What are the common faults of indoor AC high-voltage vacuum circuit breakers?

1.1 Arc Extinguishing Chamber

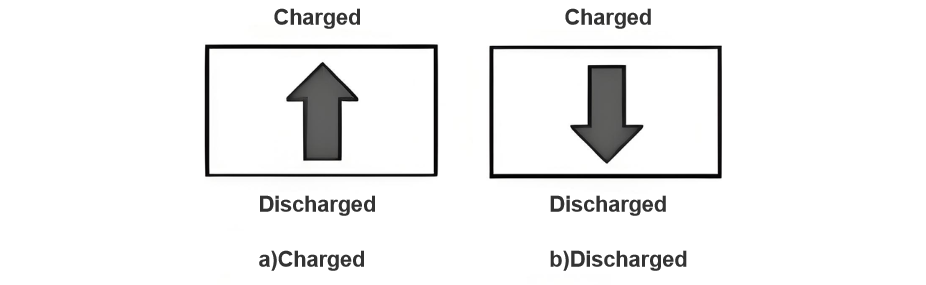

1.3.1 Energy Storage Action

1.4.1 Daily Inspection

(2) Verify that all interlock protections and signal relays are functioning normally.

(3) Ensure ammeters, voltmeters, integrated protections, and all indicator lights are in normal condition.

(2) On the weekly maintenance day, with the main machine shut down, turn the high-voltage cabinet knob to "Local", withdraw the circuit breaker trolley from the "Working Position" to the "Test Position", and inspect the electrical and mechanical components of the circuit breaker trolley for integrity.

(3) Check the tightness of bolts on all components and tighten loose bolts promptly. Regularly inspect the operating conditions of the energy storage motor, closing coil, and opening coil.

(2) Apply imported German lubricating grease to the transmission parts of the circuit breaker.

(3) Apply new conductive paste to the contact parts of the circuit breaker.

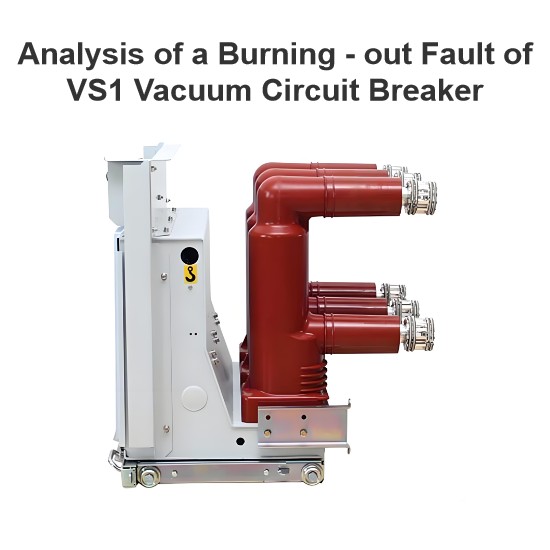

Cause Analysis:

- Faulty microswitch S1 for energy storage, preventing the energy storage motor from running normally.

- Malfunctioning limit contacts for the test/working position of the high-voltage vacuum circuit breaker, disabling the energy storage motor.

- Broken spring-hanging crank arm on the drive energy storage shaft, where the energy storage motor runs but the closing spring does not stretch.

Cause Analysis:

- Defective microswitch S1: after normal energy storage, the S1 contact fails to close.

- Faulty working position limit contacts of the high-voltage vacuum circuit breaker, which do not close properly.

- Malfunctioning auxiliary switch QF linked to the circuit breaker main shaft.

- Broken mechanical cam connecting rod, hindering normal closing operation of the mechanical mechanism.

Cause Analysis:

- Burned opening coil, disabling electric opening.

- Faulty auxiliary switch QF linked to the circuit breaker main shaft, preventing normal electric opening.

- Circuit breaker is in the closed state.

- Pushing handle is not fully inserted into the pushing hole.

- Pushing mechanism not fully in the test position, causing the tongue plate to fail to unlock with the cabinet.

- Cabinet grounding knife is not disconnected.

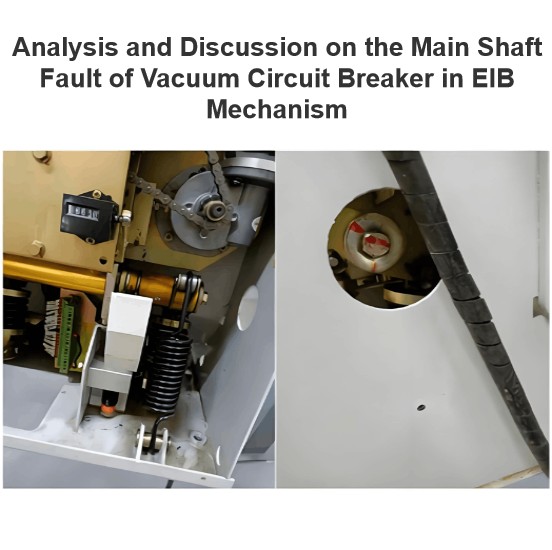

Diagnosis and Troubleshooting Process

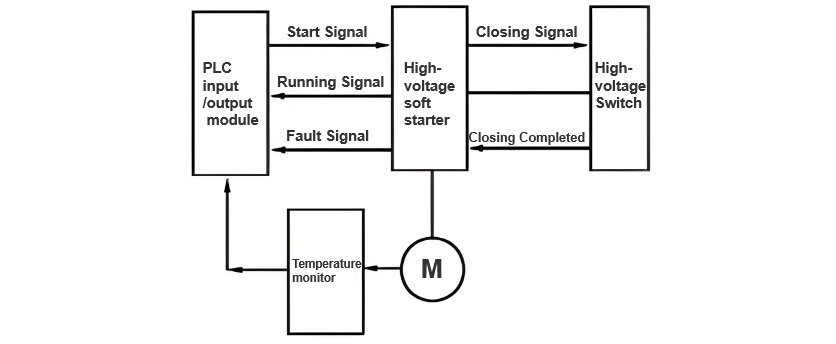

After diagnosis, during the startup process, the PLC sent the motor start command to the soft starter. The soft starter received the closing command, and the relay control board, after calculation, output the closing command to the high-voltage cabinet. However, the high-voltage cabinet did not execute the closing command. The inspection process was as follows:

- The energy storage indicator light of the high-voltage cabinet was on, indicating that the high-voltage vacuum circuit breaker had stored energy.

- A multimeter was used to measure the voltage between terminals ln4X1 and ln4x6 of the NARI integrated protection device. It should be DC 220 V. After measurement, the voltage was normal.

- The indicator light for the trolley operation position was checked. It was on, indicating that the high-voltage vacuum circuit breaker was in the working position.

- The knob was in the "Remote" position, and the indication was correct.

- When attempting remote closing again, the high-voltage vacuum circuit breaker still did not act.

- The knob was rotated to "Local", and the trolley was shaken from the working position to the test position. The plug was removed, and terminals 10# and 20# of the plug were measured. It was found that the resistance of these two terminals was very small. Under normal circumstances, it should be 12,000 Ω, indicating that the locking electromagnet coil was burned out.

- In the test position, energy storage was carried out first, and the S1 microswitch was measured, which worked normally.

- In the test position, energy storage was carried out first, and the locking contact was manually closed. The resistance of terminals 4# and 14# of the plug was measured to be 198 Ω, indicating that the closing coil was normal.

Hey there! I'm an electrical engineer specializing in Failure and Maintenance. I've dedicated my career to ensuring the seamless operation of electrical systems. I excel at diagnosing complex electrical failures, from malfunctioning industrial motors to glitchy power distribution networks. Using state - of - the - art diagnostic tools and my in - depth knowledge, I pinpoint issues quickly. On this platform, I'm eager to share my insights, exchange ideas, and collaborate with fellow experts. Let's work together to enhance the reliability of electrical setups.