VS1 Indoor High - Voltage Vacuum Circuit Breaker Fault Analysis and Improvement Measures

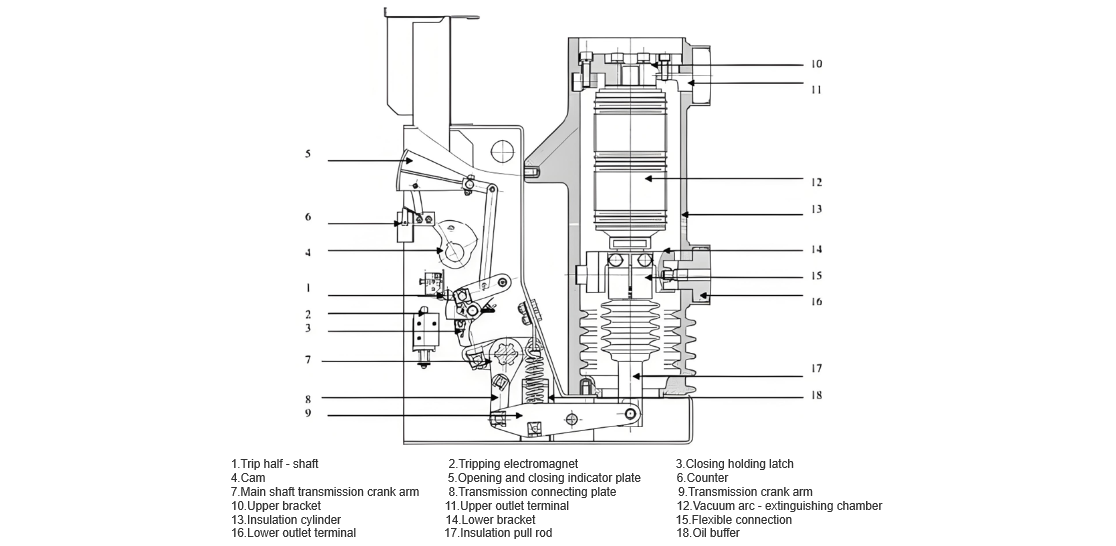

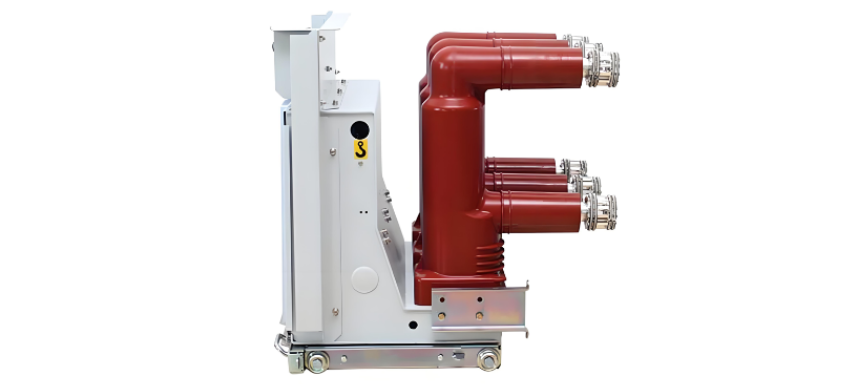

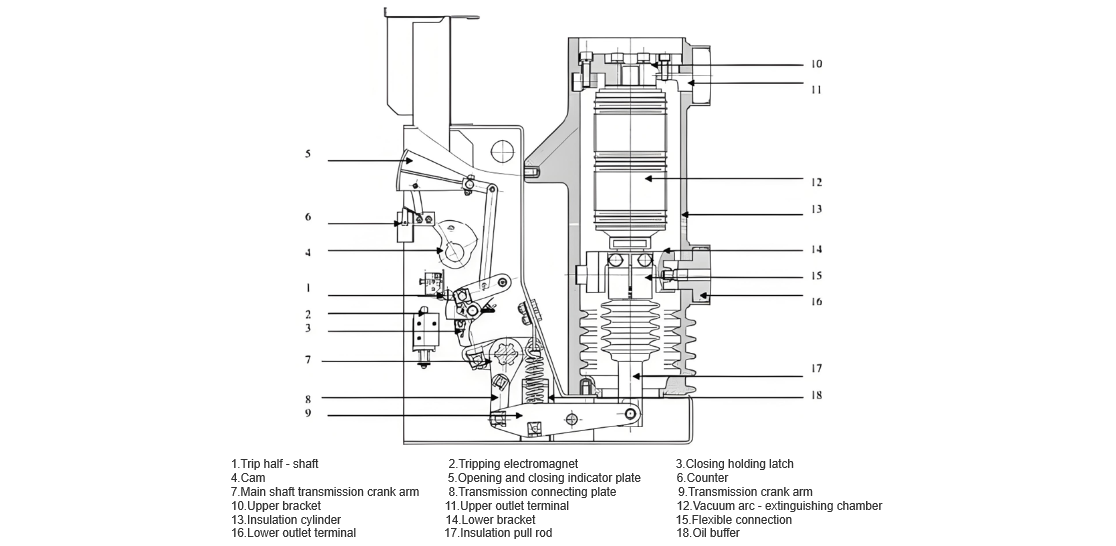

The VS1 indoor high - voltage vacuum circuit breaker is an indoor switching device used in 12 kV power systems. Due to its excellent performance, it is especially suitable for places that require frequent operation at rated working current or multiple interruptions of short - circuit current. The operating mechanism of the VS1 indoor high - voltage vacuum circuit breaker is integrated with the circuit breaker body.

It can be used not only to form a trolley unit with a special propulsion mechanism but also as a fixed - installation unit. Moreover, the fixed - type circuit breaker can improve the reliability of the mechanical interlock. This paper analyzes a burning - out fault of a VS1 vacuum circuit breaker and proposes improvement measures in terms of material selection, installation, operation, and maintenance for reference.

1. Fault Situation

In April 2024, the No. 224 circuit breaker (VS1 vacuum circuit breaker) of the X - capacitor bank in a 220 kV substation tripped due to a fault. After inspection by on - site operating personnel, it was found that the moving and static contacts and the contact arms of phase W of the circuit breaker were severely burned out and could not be re - put into operation. The situation was reported immediately. After the maintenance personnel arrived at the site, with the approval of the dispatching department, the No. 224 circuit breaker and the 10 kV busbar were shut down.

At 13:00 on the same day, an accident emergency repair order was filled out for defect handling. The maintenance personnel inspected the relevant parts of the accident switch on - site and found that the moving and static contacts of phase W of the No. 224 circuit breaker and the contact box in the cabinet were severely burned out.

2. Fault Cause Analysis

The No. 224 circuit breaker of the X - capacitor bank has a model of VS1 - 12/T1250 - 25 and was put into operation on June 3, 2005. After a comprehensive inspection, the following analysis of the accident situation is made based on the actual on - site situation:

- Main Cause: The aging of the spring of the plum - blossom moving contact of the circuit breaker body is the main cause of this accident. During the on - site maintenance process, the maintenance personnel found that the most severely burned - out component was the spring of the plum - blossom moving contact. The on - site situation was that most of the spring of the moving contact of phase W had completely melted, and the spring of the moving contact of phase V had experienced annealing. By comparing the old and new contacts, it can be seen that due to the long operation time of the No. 224 circuit breaker, the spring of the old contact was severely aged, resulting in a decrease in the contact pressure of the moving contact and an increase in the contact resistance, which was prone to cause overheating. At the same time, since the circuit breaker of the capacitor bank has high requirements for the breaking capacity of large currents and the capacitor switching is relatively frequent, during the breaking process, it is easy to cause the moving and static contacts to be in poor contact, which also causes the spring to age and leads to virtual - connection discharge, resulting in the burning - out of the contacts.

- Secondary Cause: The long - term operation of the circuit breaker body and the oscillatory displacement of the car body is the secondary cause of this accident. The No. 224 circuit breaker has been in operation or hot standby for a long time. During the switching process of the capacitor bank, the circuit breaker body vibrates, causing the car body to shift slightly, which makes the contact between the three - phase moving and static contacts shift. When the maintenance personnel carried out the rack - in and rack - out operations on - site, they found that there was a certain gap between the car body and the cabinet track. During the long - term switching operation of the circuit breaker, the trolley may shift (by comparing the burned - out phase W with the other two non - faulty phases, this conclusion can be drawn. The spring and contact fingers of the moving contact of phase V had experienced annealing, while the moving contact of phase U had not changed at all). Based on this judgment, when the accident occurred, the contact size of the moving and static contacts of phase U was normal, the contact of the moving and static contacts of phase V was a little shallow, and phase W was in virtual connection or had an unqualified contact size.

3. Fault Handling Situation

The maintenance personnel replaced the moving and static contacts of phase W of the No. 224 circuit breaker and the contact box in the cabinet on - site. After completion, they carried out mechanical characteristic tests and contact resistance measurements on the No. 224 circuit breaker. At the same time, they carried out withstand voltage tests on the 10 kV busbar and the No. 224 circuit breaker. All tests were qualified, meeting the requirements for commissioning. Power supply was restored at 17:00 on the same day.

4. Improvement Measures

- Material Selection: Strictly control the material selection of all components of the incoming - network vacuum circuit breaker. For the selection of the material and mechanical dimensions of components such as plum - blossom contacts, operating mechanisms, and secondary plugs, strictly follow the product technical requirements to improve the reliability of the equipment.

- Installation Process: Strengthen the installation process of the trolley and the cabinet of the vacuum circuit breaker. The trolley and the circuit breaker must be installed firmly and reliably. The trolley should move in and out of the cabinet flexibly without jamming. When the trolley is in the operating, maintenance, or standby position, it should be firmly fixed. At the same time, the contact pressure and insertion depth of its moving and static contacts should meet the product technical requirements. It is strictly prohibited to have insufficient contact pressure or oscillatory displacement.

- Equipment Inspection: Strengthen the inspection of equipment. Strengthen the overall inspection of the 10 kV capacitor bank circuit breakers with VS1 vacuum circuit breakers in the cabinet. Conduct regular inspections according to the number of switching operations to ensure that the contact pressure of the moving and static contacts meets the requirements for the safe and stable operation of the equipment.