Puffer interruption in gas HV CB

Detailed Explanation of the Arc Quenching Process in a Puffer-Type SF6 Circuit Breaker

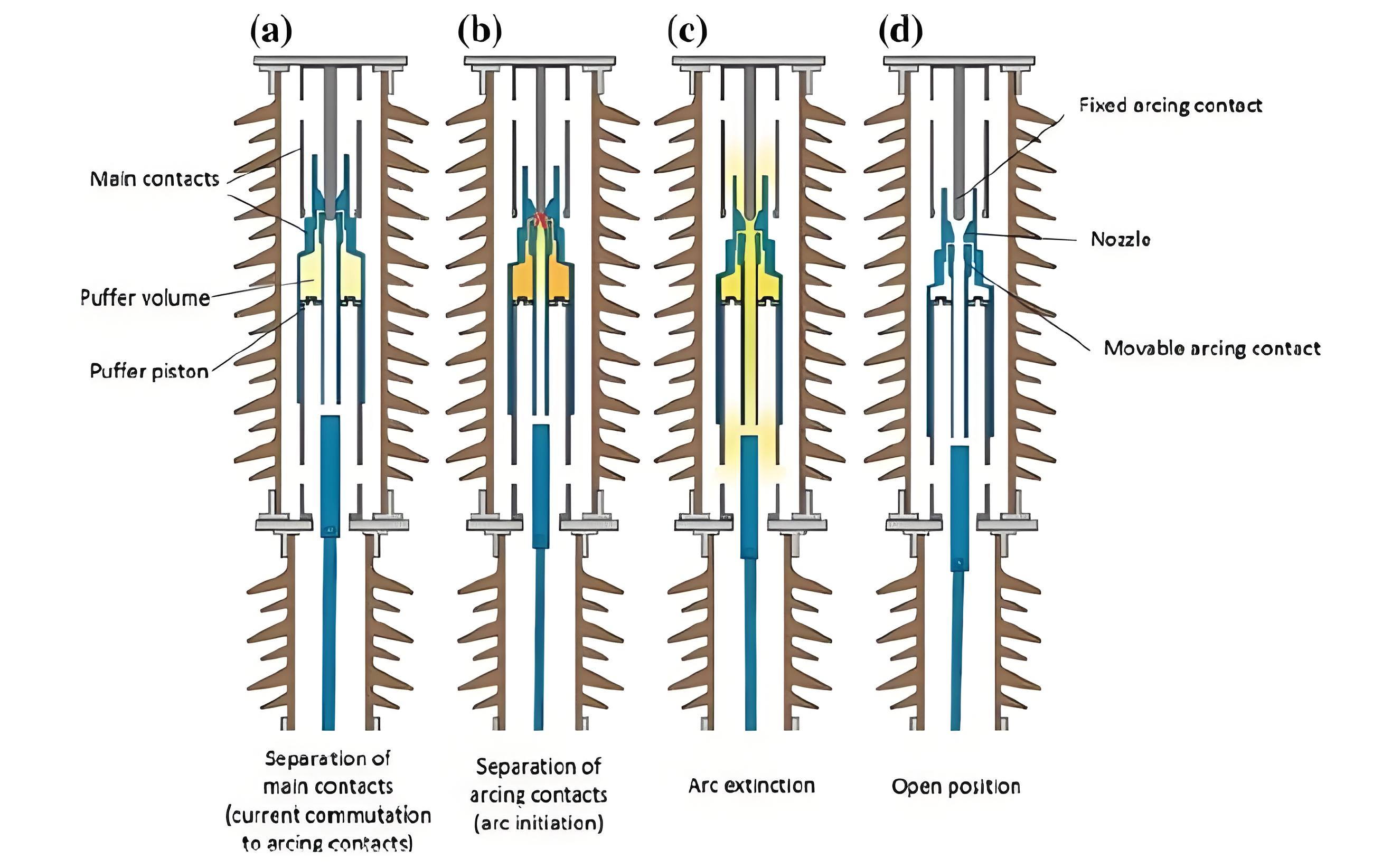

In a puffer-type SF6 circuit breaker, the arc quenching process is a critical mechanism that ensures the reliable interruption of high currents, especially during short-circuit conditions. The process involves the interaction between the main contacts, arcing contacts, and a PTFE (Polytetrafluoroethylene) nozzle, which guides the flow of compressed SF6 gas to extinguish the arc. Below is a detailed explanation of the arc quenching process, step by step:

- Initial State: Main Contacts Open, Current Commutated to Arcing Contacts

- Main Contacts: The main contacts, which are larger and designed for carrying normal load current, are placed concentrically outside the arcing contacts. In this initial state, the main contacts have already opened, and the current has been transferred (commutated) to the arcing contacts.

- Arcing Contacts: The arcing contacts are smaller and specifically designed to handle the high temperatures and pressures generated during arcing. They are about to open, and as they do, an arc will ignite between them.

- Arc Ignition: Arcing Contacts Begin to Separate

- As the arcing contacts start to separate, the current continues to flow through the small gap between them, forming an arc. At this point, the arc is still relatively stable, and the PTFE nozzle, which is fixed to the moving contact, begins to guide the compressed SF6 gas from the puffer volume toward the arc.

- The flow of gas is initially limited because the arc cross-section may be large, especially at high short-circuit currents. This phenomenon, where the arc cross-section is larger than the nozzle throat diameter, is known as current clogging. During current clogging, the gas flow is partially blocked by the arc, preventing it from effectively cooling the arc.

- Gas Pressure Build-Up and Arc Constriction

- Mechanical Movement and Heat Transfer: As the arcing contacts continue to separate, the mechanical movement of the contacts further compresses the SF6 gas in the puffer volume. Additionally, heat from the arc is transferred to the gas, causing its temperature to rise rapidly. This combination of mechanical compression and heat transfer leads to a significant increase in gas pressure within the puffer volume.

- Approach to Current Zero Crossing: As the arc approaches its natural zero crossing (the point where the alternating current passes through zero), the arc's cross-section begins to decrease. This reduction in arc size allows the compressed SF6 gas to flow more freely through the nozzle.

- Powerful Gas Blast: Just as the arcing contacts fully separate, the compressed gas in the puffer volume is released through the nozzle, creating a powerful blast that blows directly onto the arc. This high-velocity gas flow cools the arc rapidly, stretches it, and disrupts the ionized plasma, leading to the extinction of the arc.

- Arc Extinction and Dielectric Strength Recovery

- Arc Extinguishment: Once the arc is extinguished at the current zero crossing, the flow of current ceases, and the arc no longer exists. The absence of the arc means that the heat source is removed, allowing the SF6 gas to cool down.

- Recombination of Gas Particles: After the arc is extinguished, the decomposed SF6 gas particles (such as SF4, S2F10, etc.) begin to recombine, restoring the original chemical structure of SF6. This recombination process also restores the insulating properties of the gas.

- Dielectric Strength Recovery: The rapid recombination of gas particles and the cooling of the gas lead to a quick recovery of the dielectric strength between the contacts. This ensures that the arc does not reignite when the voltage across the contacts increases after the current has passed through zero.

- Contact Movement Stops: With the arc extinguished and the dielectric strength restored, the movement of the contacts stops. The gas pressure inside the circuit breaker (CB) then stabilizes, and the system returns to a normal, non-conductive state.

Key Points to Note:

- Current Clogging: At high short-circuit currents, the arc cross-section can be larger than the nozzle throat diameter, temporarily blocking the gas flow. This phenomenon is called current clogging. Despite this, the gas pressure continues to build up due to mechanical compression and heat transfer from the arc.

- Puffer Volume and Nozzle Design: The puffer volume is a crucial component that stores the compressed SF6 gas, which is then released through the PTFE nozzle. The nozzle is designed to direct the gas flow precisely onto the arc, ensuring effective cooling and arc quenching.

- Rapid Dielectric Strength Recovery: One of the key advantages of SF6 gas is its ability to quickly recover its insulating properties after the arc is extinguished. This ensures that the circuit breaker can safely interrupt high currents without risking arc reignition.

Conclusion

The puffer-type SF6 circuit breaker's arc quenching process is a highly efficient and reliable method for interrupting high currents, especially during short-circuit conditions. The combination of mechanical compression, gas flow, and the unique properties of SF6 gas ensures that the arc is rapidly extinguished, and the dielectric strength between the contacts is quickly restored. This design allows the circuit breaker to handle large fault currents while maintaining the integrity and safety of the electrical system.