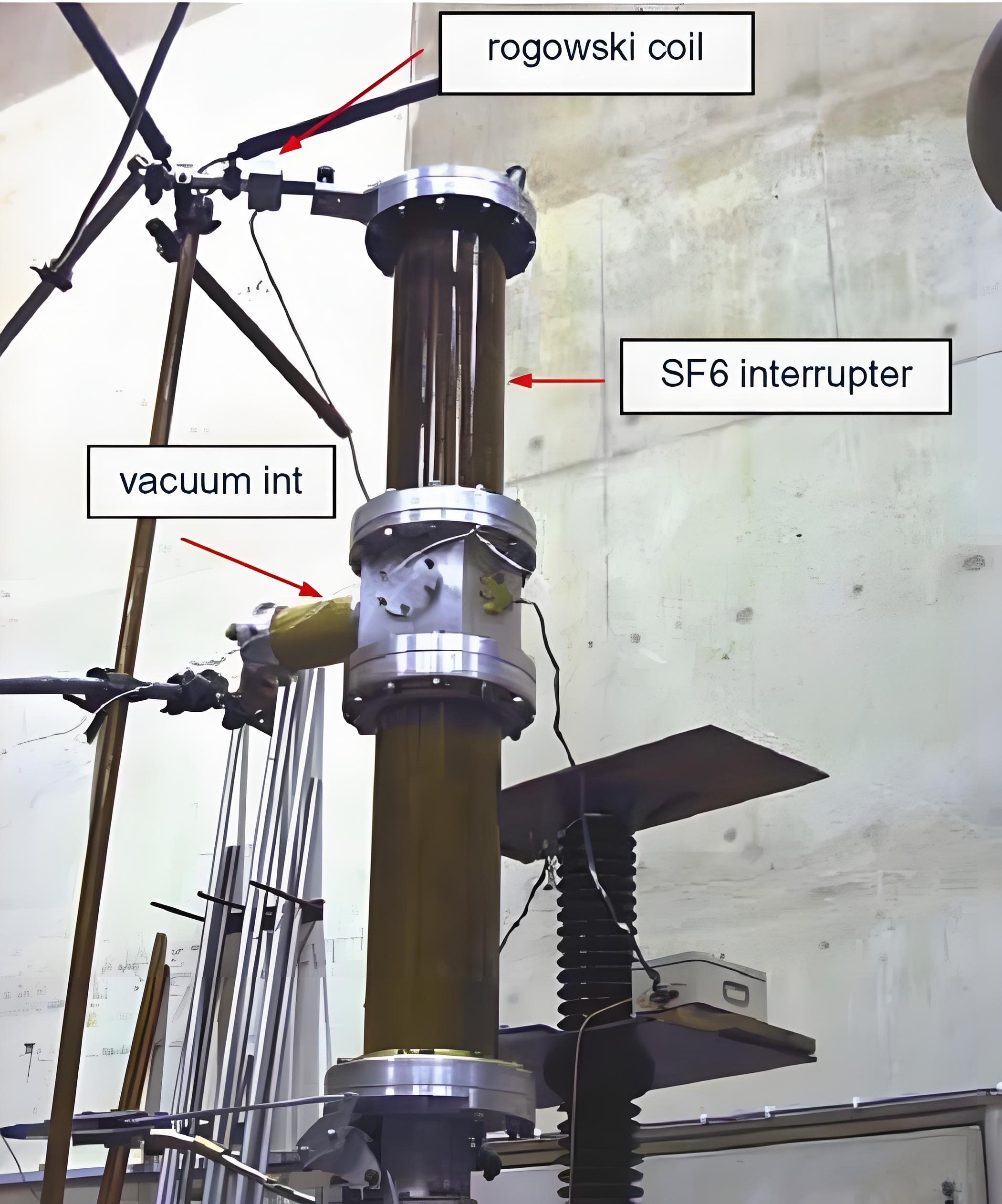

Hybrid (vacuum-gas) high voltage circuit breaker prototype

Summary of Hybrid Circuit Breaker Benefits

Hybrid circuit breakers (CBs) represent a significant advancement in high-voltage switching technology, combining the advantages of both vacuum and SF6 (now CO2) interrupters. The hybrid design leverages the unique properties of each interrupter to achieve superior performance and environmental benefits. Below is a summary of the key benefits:

1. Enhanced Interruption Performance

- Synergistic Arc Interaction: The hybrid CB design allows for a synergistic interaction between the vacuum and CO2 arcs, which improves the overall interruption process:

- Before Current Zero: The CO2 arc assists the vacuum arc in the final stages of current interruption, helping to extinguish the arc more effectively.

- After Current Zero: The vacuum arc supports the CO2 arc during the recovery phase, providing better resistance against the transient recovery voltage (TRV). This ensures a more reliable and stable interruption, especially under steep-rising TRVs.

- High Interrupting Capacity: The combination of vacuum and CO2 interrupters allows the hybrid CB to handle very high short-circuit currents (e.g., 63 kA) without the need for additional capacitors or complex auxiliary equipment. This results in a more compact and efficient design.

2. Environmental Sustainability

-

Elimination of SF6 Gas: One of the most significant advantages of hybrid CBs is the replacement of SF6 gas with CO2. SF6 is a potent greenhouse gas with a global warming potential thousands of times greater than CO2. By using CO2 as the interrupting medium, hybrid CBs significantly reduce the environmental impact associated with SF6 emissions.

-

No Environmental Concerns: CO2 is a non-toxic, non-flammable, and readily available gas, making it a safer and more environmentally friendly alternative to SF6. This also simplifies disposal and maintenance processes, further reducing the environmental footprint of the device.

3. Improved Operation at Low Ambient Temperatures

- Cold Weather Performance: Hybrid CBs are designed to function effectively in low-temperature environments. Unlike traditional SF6-based CBs, which can experience reduced performance or operational issues at low temperatures, hybrid CBs maintain their high interrupting capacity even in extreme cold conditions. This makes them suitable for use in a wide range of climates, including regions with harsh winter conditions.

4. Compact Design and Reduced Size

-

Advanced Vacuum Technology: Recent advancements in vacuum interrupter technology have enabled the development of smaller, more efficient vacuum bottles that can handle very high short-circuit currents. This reduction in size contributes to a more compact hybrid CB design, which is easier to install and integrate into existing power systems.

-

No Additional Capacitors Required: The hybrid design eliminates the need for external capacitors to assist with interruption, further reducing the overall size and complexity of the device. This results in a more streamlined and cost-effective solution.

5. Reliability and Longevity

-

Robust Performance: The combination of vacuum and CO2 interrupters provides a highly reliable and durable solution for high-voltage switching applications. The vacuum interrupter's ability to withstand steep-rising TRVs, coupled with the CO2 interrupter's excellent arc-quenching properties, ensures consistent performance over time.

-

Long Maintenance Intervals: Due to the robust design and the use of environmentally stable materials, hybrid CBs require fewer maintenance interventions compared to traditional SF6-based CBs. This reduces downtime and operational costs.

Conclusion

Hybrid circuit breakers offer a compelling solution for high-voltage switching applications, combining the best features of vacuum and CO2 interrupters. They provide enhanced interruption performance, environmental sustainability, improved low-temperature operation, and a compact design. These benefits make hybrid CBs an attractive option for modern power systems, particularly in environments where environmental concerns and operational reliability are critical factors.