Contact Nozzle Ablation in high voltage sf6 circuit breaker

Inspection and Maintenance of High-Voltage SF6 Circuit Breaker Nozzles

1. Background and Traditional Inspection Methods

High-voltage SF6 circuit breakers are widely used in power systems to protect circuits from short circuits and overloads. To ensure their reliability and safety, manufacturers typically require periodic disassembly and visual inspection of the main contacts, arc contacts, and gas nozzles. These inspections aim to assess the wear condition of these components and determine whether replacement is necessary.

Historically, these inspections have been based on several criteria:

- Time Interval: For example, it is recommended to inspect the contacts after 12 years of use for single-pressure SF6 dead-tank circuit breakers.

- Electrical Operations: For instance, inspections are advised after 2000 electrical operations.

- Fault Operations: For example, inspections are recommended after 10 rated short-circuit breaker operations.

- Combined Criteria: A combination of the above factors is sometimes used for a more comprehensive assessment.

However, over time, these time-based and operation-count-based inspection methods have revealed some limitations. While these checks help ensure equipment safety, they do not always accurately reflect the actual wear condition of the contacts and nozzles. Additionally, these inspections can be costly, inconsistent, and pose potential risks during on-site internal inspections, which may lead to equipment damage.

2. Impact of Arcing on Circuit Breaker Parameters

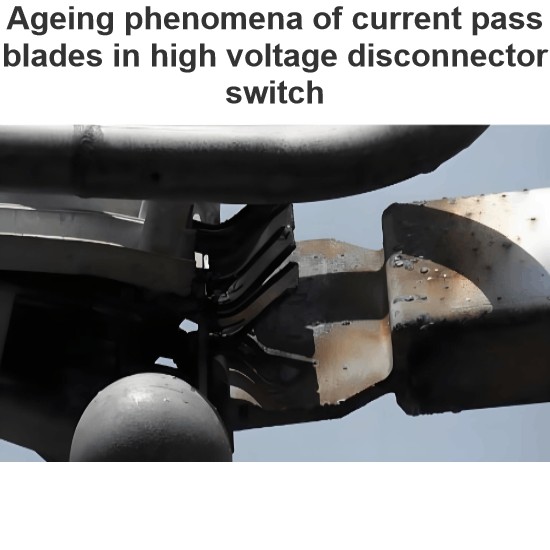

Arcing is a complex thermal and electrical process that significantly affects the performance of a circuit breaker. During the interruption of short-circuit currents, arcing can impact the breaker's parameters through nozzle ablation. Nozzle ablation refers to the erosion of nozzle material caused by the high temperature of the arc. This process has a dual effect on the breaker's interrupting capability:

- Increased Chamber Pressure: As the nozzle ablates, the cross-sectional area of the nozzle throat increases, leading to higher pressure within the breaker chamber. This increased pressure helps accelerate arc extinction by suppressing re-ignition.

- Increased Nozzle Throat Cross-Sectional Area: The enlargement of the nozzle throat allows more gas to flow into the arc region, carrying away more heat and reducing the arc temperature. However, this also disperses the arc energy, potentially weakening the self-blast capability of the breaker.

Thus, the nozzle ablation process has both positive and negative effects on the interrupting capability of a self-blast circuit breaker. When the breaker interrupts a short-circuit current, nozzle ablation removes part of the arc column's energy, increases the mass of gas in the nozzle space, and raises the gas density around the arc contacts, thereby reducing the likelihood of re-ignition.

3. Estimation of Nozzle Ablation Intensity and Its Importance

Given the significant impact of nozzle ablation on breaker performance, estimating the ablation intensity (i.e., the increase in nozzle throat diameter) and calculating the ablated mass is a crucial task. Accurate estimation of nozzle ablation helps maintenance personnel better understand the health of the breaker and make informed decisions for future maintenance.

The ablation intensity can be estimated through the following methods:

- Visual Inspection: By disassembling the breaker and directly observing the wear on the nozzle. Although this method is straightforward, it is costly and carries inherent risks, as mentioned earlier.

- Non-Intrusive Detection Techniques: Advanced non-intrusive detection technologies, such as infrared thermography and ultrasonic testing, are increasingly being used for breaker maintenance. These techniques allow for the assessment of nozzle ablation and other potential issues without disassembling the equipment.

- Data Analysis and Predictive Modeling: By analyzing historical operating data of the breaker and combining it with arc physics models, predictive models can estimate the nozzle ablation intensity. This approach reduces unnecessary disassembly inspections and improves maintenance efficiency.

4. Future Development Directions

To enhance the maintenance efficiency and reliability of high-voltage SF6 circuit breakers, future maintenance strategies may rely more on condition monitoring and intelligent diagnostic technologies. Real-time monitoring of the breaker's operating parameters (such as current, voltage, and temperature), combined with advanced data analysis algorithms, can provide a more accurate prediction of nozzle ablation and the overall health of key components. This approach can reduce unnecessary inspections and repairs, extend the equipment's lifespan, and lower maintenance costs.

Additionally, advancements in materials science will focus on developing more heat-resistant and ablation-resistant nozzle materials. The application of new materials can further improve the breaker's reliability and interrupting capability, mitigating the negative effects of nozzle ablation.

Measurement Method for Nozzle Ablation in High-Voltage Circuit Breakers

1.Principles of Nozzle Ablation Measurement

1.1 Relationship Between Pressure Signals and Nozzle Ablation

Research has demonstrated that nozzle ablation, which increases the nozzle throat diameter, alters the gas flow characteristics within the circuit breaker. This change affects the pressure distribution, leading to variations in the pressure signals that can be captured by pressure sensors. Specifically, nozzle ablation results in two primary effects:

- Changes in Pressure Waveform: An increase in nozzle diameter modifies the gas flow resistance, altering the shape of the pressure waveform.

- Changes in Spectral Characteristics: Nozzle ablation also influences the spectral characteristics of the pressure signals, particularly in the high-frequency range.

By analyzing these pressure signal features, it is possible to indirectly infer the extent of nozzle ablation.

1.2 Installation and Measurement of Pressure Sensors

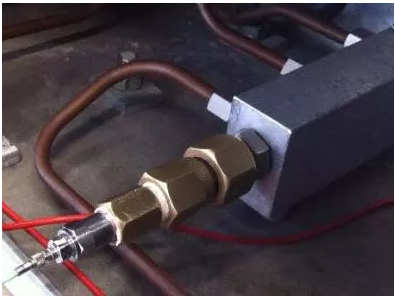

To obtain accurate pressure signals, pressure sensors can be installed at different points depending on the circuit breaker's structure and measurement requirements:

- Single-Pole Measurement: Each pole has a valve at its bottom, which can be used to connect pressure sensors. This setup allows for the measurement of pressure waves from a single pole, avoiding interference from multi-pole signal superposition.

- Three-Pole Measurement: During standard operation, the three poles are connected via copper tubes, with a main filling valve located inside the circuit breaker base, connecting all three poles. If the main filling valve is used as the connection point for the pressure sensor, the measured signal will be the superposition of three individual pressure signals.

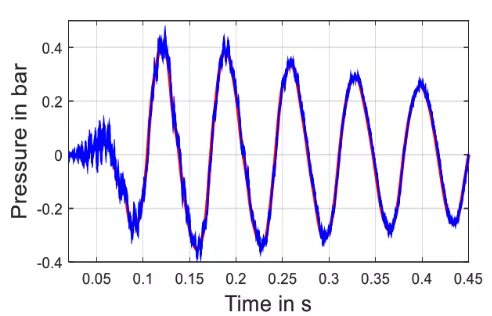

To ensure accurate measurements, high-sensitivity piezoelectric pressure sensors equipped with appropriate charge amplifiers are used. Pressure data are recorded from the start of the switching operation until the end of the sixth oscillation. The raw pressure signal can be processed either with or without filtering, depending on the analysis requirements.

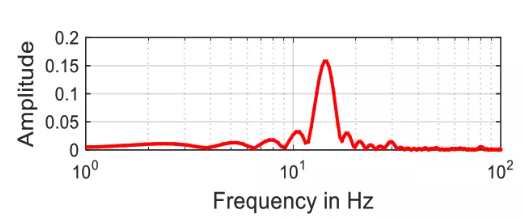

- Unfiltered Signal: The Fast Fourier Transform (FFT) is applied directly to the unfiltered signal to analyze its frequency domain characteristics.

- Filtered Signal: A 100 Hz low-pass filter is used to remove high-frequency noise, retaining only the low-frequency components.

Figures 1 and 2 illustrate the pressure history and spectrum, providing a visual representation of the pressure signal characteristics.

- Nozzle Condition Classification Using Machine Learning

To enhance the accuracy of the diagnosis, this study employs a machine learning algorithm based on the k-Nearest Neighbors (k-NN) method. The process involves the following steps:

- Feature Extraction: Key features are extracted from the pressure signals, such as peak and valley values, frequency components, etc. These features serve as input parameters for the machine learning algorithm.

- Model Training: The k-NN model is trained using known data on nozzle and electrode conditions. During training, the algorithm determines the nearest neighbors based on feature distances to perform classification.

- Classification of New Data: For new, unknown measurements, the trained model is used to classify the condition of the nozzles and electrodes.

This approach enables the assessment of nozzle ablation and other critical component conditions without opening the gas chamber, providing accurate maintenance recommendations and extending the lifespan of the circuit breaker.

Connection point with pressure sensor for nozzle ablation(photo from the source no 1)

Connection point with pressure sensor for nozzle ablation(photo from the source no 1)

Raw data of measurement at the main filling valve in original condition (blue), filtered signal (red)(photo from the source no 1)

Frequency spectrum of raw data in high voltage circuit breaker pressure method(photo from the source no 1)

Conclusion of the Transient Pressure Method for High-Voltage Circuit Breaker Nozzle Ablation

1. Feature Extraction from Filtered and Unfiltered Pressure Signals

Several features can be derived from both filtered and unfiltered pressure signals. These features capture the unique characteristics of different measurement signals and are essential for identifying the condition of the nozzles. Due to the wide dispersion of these features, it is not feasible to directly match different ablation conditions with individual features. To address this challenge, the k-Nearest Neighbors (k-NN) algorithm is employed for evaluation.

The k-NN algorithm generates an n-dimensional vector for each measurement, where n represents the number of features. The distance between two vectors is calculated using the Euclidean distance, with an additional variance weighting to account for the variability in the data. This approach ensures that the algorithm can effectively distinguish between different ablation conditions based on the combined information from multiple features.

2. Advantages and Challenges of the Transient Pressure Method

The transient pressure method is advantageous because it can be easily implemented using existing filling valves to connect pressure sensors. However, one of the main challenges is the poor dispersion of state indicators (features), which makes it difficult to diagnose nozzle conditions accurately. To overcome this limitation, the feature scales were optimized through sensitivity analysis. While a single feature may not provide sufficient information for all cases, combining all seven features with the k-NN classification algorithm significantly improves diagnostic accuracy.

3. Evaluation of Classification Algorithms

Several classification algorithms were tested, and the results showed that the k-NN algorithm, using standard Euclidean distance, achieved the lowest error rate of less than 0.9% during cross-validation. This combination of features and the k-NN algorithm was then applied to classify field measurements for different types of circuit breakers. For the considered circuit breaker measurements, this approach was able to perform the classification without any errors.