Brief History of the Past and Present of High voltage Vacuum Circuit Breakers

High Voltage Vacuum Circuit Breakers: An Overview

Introduction

High voltage vacuum circuit breakers (HV VCBs) have emerged as a viable alternative to traditional SF6 gas-insulated circuit breakers, particularly in applications where frequent switching and lower maintenance costs are critical. Since 2014, HV VCBs have been increasingly adopted as an alternative to high-voltage gas circuit breakers, offering a greener and more sustainable solution by eliminating the use of SF6, a potent greenhouse gas.

Vacuum switchgear has been extensively used in distribution systems for over three decades, primarily for making and breaking fault currents and switching loads of various types. The reliability and performance of vacuum switching technology in the medium voltage range (up to 52 kV) have been exceptional, leading to its dominance in distribution systems. However, efforts to extend vacuum switching technology to transmission voltage levels began as early as the 1960s, with significant milestones achieved around 1980 when the first high-voltage vacuum circuit breakers were installed in Japan. By 2010, approximately 10,000 HV VCBs were in operation, mainly in industrial settings but also in utility applications. The preference for vacuum technology over SF6 was driven by its ability to handle frequent switching operations and lower maintenance requirements.

In the United States, vacuum capacitor bank switches have been used for several decades at voltages up to 242 kV. Around 2008, intensive research and development (R&D) programs in China and Europe aimed to develop HV VCBs, with a focus on reducing or eliminating the use of SF6. This led to the introduction of products capable of operating at voltages up to 145 kV. In China, the rapid adoption of HV VCBs in commercial applications is expected to continue, with hundreds of units already in service at voltage levels up to 126 kV. In Europe, field tests are ongoing to validate the performance of type-tested devices before they enter the market.

Technology and Design

All HV VCB products are based on the well-established medium voltage vacuum interrupter technology, which has been refined over the years. No fundamentally new technical features were required to extend this technology to higher voltage levels. The primary challenge lies in scaling the geometry of the interrupter to accommodate the higher voltage ratings. For example, the diameter and contact gap length must be increased to handle voltages above 52 kV. In some cases, for voltages exceeding 126 kV, two vacuum gaps in series are employed to ensure reliable operation.

Operational Features

- Normal Current Handling: For normal currents up to 2,500 A, there are no significant differences between HV VCBs and SF6 circuit breakers. However, achieving higher current ratings (above 2,500 A) in HV VCBs is challenging due to heat generation from the contact structure and the limited heat transfer capability of the interrupter.

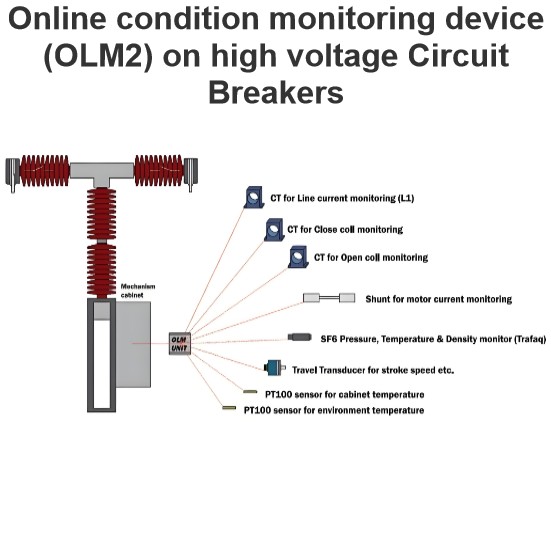

- Monitoring: It is easier to monitor the quality of the interruption medium in SF6 circuit breakers, as the degree of vacuum in HV VCBs cannot be practically monitored during service.

- Switching Operations: HV VCBs can perform a higher number of switching operations compared to SF6 circuit breakers due to the superior endurance of the vacuum contact system to arcing. This makes vacuum technology particularly attractive for applications requiring frequent switching, such as daily operations.

- Drive Energy: At a typical 72.5 kV rating, the drive energy required for a vacuum circuit breaker is significantly lower—approximately 20% of that required for an equivalent SF6 circuit breaker. The physical sizes of the two types of devices are comparable.

- Interrupter Configuration: Above 145 kV, HV VCBs may require more than one interrupter in series, whereas SF6 technology has successfully implemented single-break circuit breakers up to 550 kV since 1994, which are widely used in many countries.

- Arc Characteristics: The arc voltage in HV VCBs is much lower than in SF6 circuit breakers, typically ranging from tens of volts compared to hundreds of volts in SF6. Additionally, the duration of the arc during fault switching is shorter in vacuum switchgear, with a minimum arcing time of 5–7 ms compared to 10–15 ms for SF6 circuit breakers. This results in a higher number of possible switching operations for HV VCBs.

- X-ray Emissions: HV VCBs with rated voltages up to 145 kV emit X-rays within the standardized limit of 5 µSv/h under normal operating conditions. SF6 circuit breakers do not emit X-rays.

Electrical Features

- Fault Current Interruption: HV VCBs excel in interrupting fault currents with very steep rates of rise of transient recovery voltage (TRV) due to their rapid dielectric recovery, which is faster than that of SF6 circuit breakers.

- Breakdown Statistics: While vacuum gaps theoretically have very high breakdown voltages, there is a small probability of breakdown at relatively moderate voltages. Vacuum gaps can also experience spontaneous late breakdown, occurring up to several hundred milliseconds after current interruption. However, the consequences of such events are limited because the vacuum gap immediately restores its insulation. The system implications of late breakdown are not yet fully understood.

- Inductive Load Switching: In applications involving inductive loads, such as shunt reactor switching, HV VCBs tend to experience a higher number of repeated re-ignitions at one power frequency current zero. This is due to the vacuum's ability to interrupt high-frequency currents that follow re-ignition. The effects of these re-ignition transients on interacting apparatus, such as RC snubbers and metal-oxide arresters, are currently under investigation.

- Capacitor Bank Switching: When switching capacitor banks, it is crucial to avoid very high inrush currents, as they can degrade the dielectric properties of the contact system through pre-strike arcs. This challenge applies to both HV VCBs and SF6 circuit breakers. Mitigation strategies include the use of series reactors or controlled switching, though there is limited field experience with the latter for HV VCBs.

Future Prospects and Market Perception

A survey conducted among users of high-voltage switchgear revealed that the absence of SF6 is seen as the primary advantage of vacuum switchgear, provided that the external insulation is also SF6-free. However, the lack of extensive service experience at transmission voltage levels remains a significant hesitation for the widespread adoption of HV VCBs. Despite this, the environmental benefits and operational advantages of vacuum technology are driving continued interest and development in this area.

Potential users of high voltage vacuum circuit breakers (HV VCBs) frequently raise concerns about the generation of overvoltages due to current chopping and the possibility of X-ray emissions during switching operations. These issues are critical for ensuring the safe and reliable operation of HV VCBs, especially as they are increasingly considered for transmission voltage applications.

X-ray Emission

For single-break devices, X-ray emissions from HV VCBs with rated voltages up to and including 145 kV remain well below the standardized limit of 5 µSv/h under normal operating conditions. Multiple-break devices exhibit even lower levels of X-ray emissions. This is an important consideration for regulatory compliance and safety, as it ensures that HV VCBs can be deployed without posing significant radiation risks to personnel or the environment.

Pilot Projects

A large majority of respondents expressed a strong interest in initiating pilot projects to gain practical experience with HV VCB technology. Such projects would allow utilities and system operators to evaluate the performance, reliability, and operational characteristics of HV VCBs in real-world conditions. Solidly earthed networks are recommended for these pilot projects, as the network conditions in medium voltage systems are not always comparable to those in transmission voltage networks, particularly regarding earthing conditions. This approach will help ensure that the experiences gained are relevant and applicable to transmission-level applications.

Standardization

The current IEC circuit breaker standard, IEC 62271-100, has a strong focus on SF6 switching technology, which may not fully address the unique characteristics and challenges of vacuum switching. For example, test duties that are challenging for SF6, such as short-line fault tests, may not be as critical for vacuum technology. Conversely, the application of continuous recovery voltage in synthetic testing, which is less relevant for SF6, could be more important for demonstrating the absence of late breakdown in vacuum interrupters. As HV VCBs gain more traction, there may be a need to revise or supplement the existing standards to better accommodate vacuum technology.

Technical Implications of SF6-Free Design

When SF6 is absent as an external insulating medium, other technical implications must be considered. For instance, alternative insulation methods may require higher pressure, increased weight, larger footprint, or different design considerations to ensure adequate insulation performance. Manufacturers are actively exploring these alternatives to develop viable replacements for SF6, but until a new technology that can cover all voltage ratings is found, SF6 will likely remain essential for certain transmission network applications.

Manufacturer Commitment

Manufacturers are committed to developing and making available industrially viable alternatives to SF6 technology. While SF6 has been the dominant insulating gas for high-voltage applications due to its excellent dielectric properties, the environmental concerns associated with SF6, particularly its high global warming potential, have driven the search for greener solutions. HV VCBs represent one such solution, offering a sustainable alternative for applications where frequent switching and lower maintenance are required. However, the transition away from SF6 will be gradual, as manufacturers continue to innovate and refine new technologies to meet the diverse needs of the power industry.