What is Circuit Breaker Maintenance?

What is Circuit Breaker Maintenance?

Circuit Breaker Maintenance Definition

Circuit breaker maintenance involves switching off, isolating, and regularly checking and servicing the breaker to ensure reliable operation.

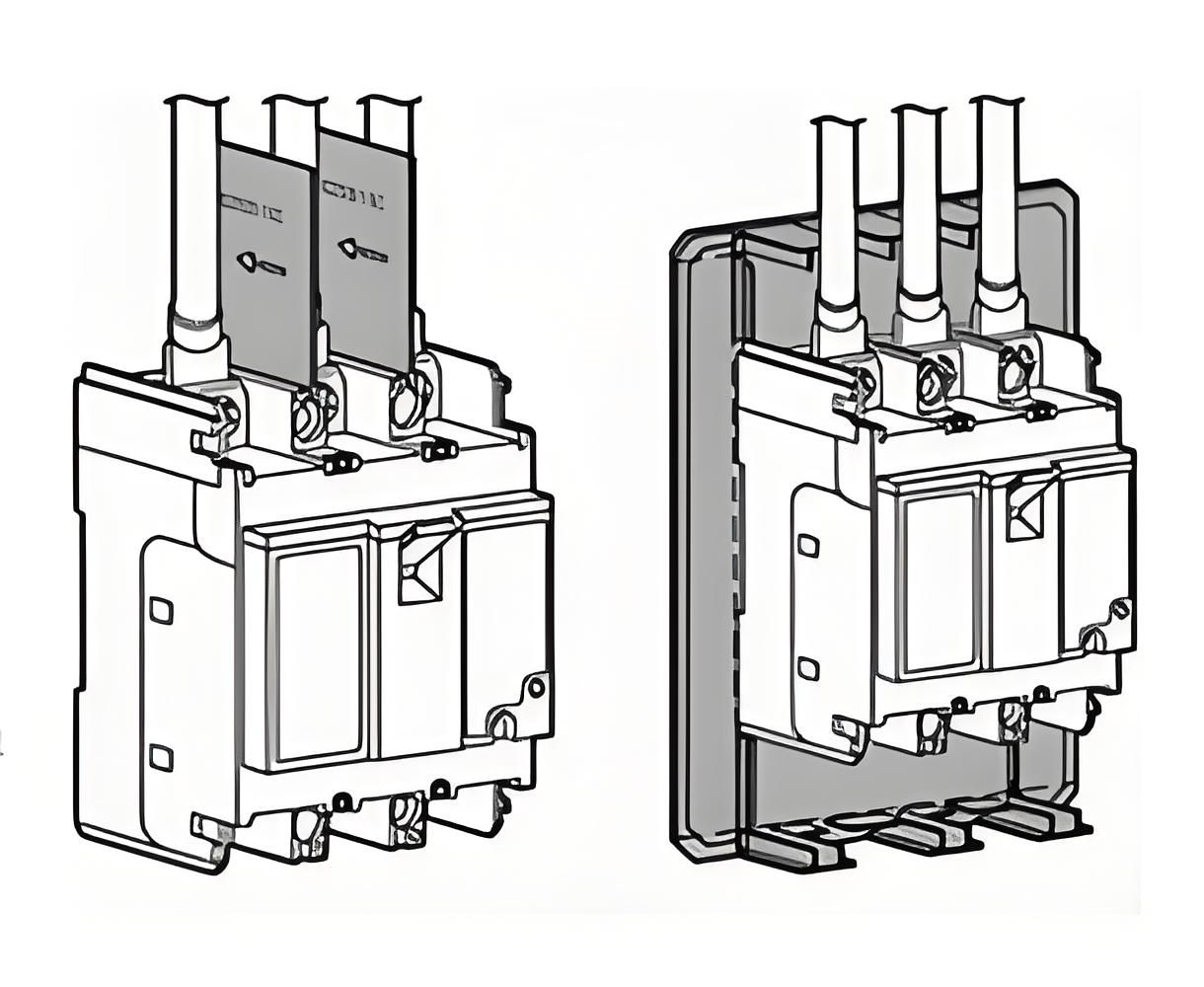

Bulk Oil Circuit Breaker

For bulk oil circuit breaker, we should check contact burning. If burning is very light, remove the burn beads and polish the surface. If burning is quite heavy, replace the tips and arcing ring by new set. We should loose and tight the tips few times before final tightening is done.

Additionally, check the extinguishing chamber. Remove it from the breaker unit, wash it with insulating oil, and keep it upside down. Replace any severely burned or damaged parts.

Next, clean and lubricate the circuit breaker mechanism. Remove rust with non-fluffy cotton cloths and lubricate the mechanism, including the gear wheel, with high-grade grease. Remember to lubricate the friction clutch. For minimum oil circuit breaker (MOCB), clean the insulator and remove any carbon deposits with Trichloroethylene or Acetone. Follow the manufacturer’s manual for detailed instructions.

Check the locking pins of the tie rods and all foundation bolts and electrical terminal connections at the circuit breaker power circuit every six months. Tighten them properly after removing any oxide coating.

The proper adjustment of auxiliary switch by ensuring correct NO NC contacts at breaker OFF and ON condition must be checked half yearly and in addition to that the auxiliary switch’s contacts should be cleaned properly with help of hard brushes.

The spring charging motor and mechanism should also be cleaned and associated bearing should also be lubricated half yearly.

Minimum Oil Circuit Breaker (MOCB) Maintenance

In case of MOCB, the breaker should be checked monthly for oil leakage and oil level. If oil leakage is found it must be attended and for low oil level top up oil up to desire level.

Perform a visual inspection of the circuit breaker, its operating mechanism, painting quality, and mechanism kiosk door gasket every quarter. Take proper action if any damage is found.

The oil dash pot in operating mechanism must be checked for oil leakage quarterly if leakage is found, replace the defective and damaged O – rings.It is also highly recommended to ensure the prescribed duty cycle of operation of the breaker including reclosing annually.

Air Blast Circuit Breaker Maintenance

For air blast circuit breaker there are some special cares to be taken in addition to general instruction for maintenance of operating mechanism. Actually for operating mechanisms and for other some features the maintenance processes and schedules are same for all oil circuit breaker, air circuit breaker, SF6 circuit breaker and vacuum circuit breaker.

In air circuit breaker, the air leakage should be checked as and when it is required. If leakage is found, plug the leakage.

The grading capacitors must be checked for oil leakage monthly. If leakage found plug it.Yearly, dew point of the operating air at the outlet of the air dryer should be measured with the help of Dew Point Meter or Hygro Meters.

SF6 and Vacuum Circuit Breaker

As we said earlier for operating mechanisms and for some other features the maintenance processes and schedules are same for all oil circuit breaker, air circuit breaker, SF6 circuit breaker and vacuum circuit breaker.

In addition to that in SF6 CB some extra care to be taken.SF6 circuit breaker must be checked for SF6 gas leakage, if unwanted SF6 low gas pressure alarm comes. This is efficiently done by gas leakage detector.If the circuit breaker is provided with gradient capacitors, these must be checked for oil leakage monthly. If leakage found plug it.Dew point of SF6 should be checked with the help of dew point meter or hygro meters in every 3 to 4 years interval.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.