Wind Energy Converter System Solution

Wind power generation control methods have evolved from simple constant pitch stall control to full blade variable pitch and variable speed control. At present, the doubly fed converter system with variable speed and constant frequency control is widely used in the wind power generation market.

Operating Principle

The rotor is excited by two back-to-back connected VSC converters with PWM. This arrangement is referred to as generator side converter and grid side converter respectively. The doubly PWM converters supply excitation current to rotor winding in order to realize the maximum capture of wind energy and the adjustment of static reactive power output. When the turbine operates at a sub-synchronous speed, power is fed into the rotor and the grid side converter runs as a rectifier while the rotor side converter runs as an inverter, providing the excitation current to the turbine. When the turbine operates at super- synchronous speed, stator and rotor can both feed energy to the grid. If the turbine operates in synchronous status, the generator runs as a synchronous motor and the converter system provides DC excitation to the rotor.

The grid side converter and the generator side converter are controlled by two control units. The grid side control unit is used to maintain DC busbar voltage stability and ensure high quality input current waveform and unit power factor. The generator side control unit is used to controls the rotor current torque and the excitation components of a doubly fed motor to adjust its active power and reactive power output, and tracks active power order and reactive power order. So that the doubly fed motor can run on the optimum power curve of wind turbine to realize the maximum capture of wind power.

System Configuration

• Cabinet Arrangement

Rockwill doubly fed converter system is especially designed for doubly fed wind power turbines. It consists of a grid interconnection/control cabinet (1200mm*800mm*2200mm, protection class is IP54), and power module cabinet (1200mm*800mm*2200mm, protection class is IP23).

-- The grid interconnection/control system is divided into two isolated cabinets, which are the control cabinet and the grid interconnection cabinet. The control cabinet is composed of controller, UPS, low voltage circuit breakers, protection devices and wiring terminals, etc. The grid interconnection cabinet incorporates a distribution transformer, main circuit breaker, grid interconnection contactor, grid side contactor, main fuse, and pre- charging resistor, etc.

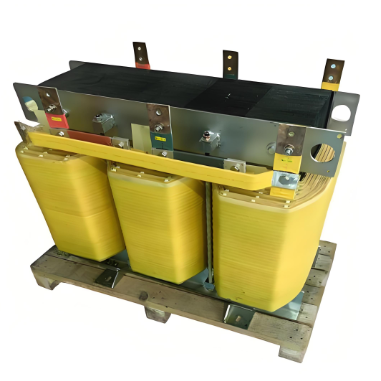

-- The power module cabinet is the main part for accomplishing current conversion. In addition, there are three power units at both grid and generator sides. Each integrate IGBT, drive board, radiator, DC capacitor, absorption capacity, temperature measuring resistor, etc. The power module cabinet also includes laminated busbar, grid side reactor, bridge arm side reactor, generator side reactor, grid side and generator side filtering resistor and capacitor, large and small fans, heater, etc.

• Primary Part

The primary part of the converter system consists of power modules, filtering system, temperature control system, precharging system, LVRT (Low Voltage Ride Through) unit and distribution system, etc.

-- The power module is composed of IGBT and its drive, protection, heat dissipation accessories. In one converter system, it includes six groups of power modules, which are connected by the laminated DC busbar.

-- The filtering system consists of grid-side LCL filter and generator-side du/dt filter. The grid-side LCL filter can effectively filter high frequency harmonics from converter to grid. The du/dt filter, together with the choking reactor in generator side, can suppress the voltage peak and fast transient voltage of rotor insulating components.

-- The temperature control system adjusts the temperature inside the cabinet is during the normal range by heating and cooling, the heating is performed by the heater inside the cabinet and the cooling is performed by the fan cooling system.

-- The pre-charging system is used to raise the DC voltage of DC capacitor to certain amplitude before the startup of the converter. Thereby, it can reduce the current impulse during converter startup.

-- The LVRT unit can protect the power semiconductor devices at generator side in case of operation fault, line fault, or rotor overvoltage. And by the LVRT unit, the converter system can supply current to the grid even in the case of grid fault, thus achieving low voltage ride through.

-- The power distribution system provides uninterrupted power supply for each active device of the converter.

• Control and Protection System

The control and protection system are the brain of the doubly fed converter system, it significantly influences the convertor's performance. The control and protection system mainly performs the following functions:

-- Control functions: grid-side control, generator-side control and LVRT control.

-- Protection functions: overcurrent protection of grid-side and generator-side converter, undervoltage and overvoltage protection of grid-side and generator-side converter, negative sequence overcurrent protection of grid-side and generator side converter, undervoltage and overvoltage protection of DC busbar, overtemperature protection of grid-side and generator-side converter, generator overspeed protection.

Features

• Fast response capabilities and high control precision;

• Complete fault recording function conformed to IEEE COMTRADE format;

• Highly reliable and flexible integrated protection system;

• Grid interconnection control strategy based on self-adaptive positioning of rotor that can realize “zero” impulse grid synchronization;

• Photo-electric encoder, which adopts software reset mode, can improve the accuracy and reliability of motor rotation speed acquisition;

• High voltage and low voltage ride through control strategies are used to guarantee the converter fault ride through capability;

• Harmonics suppression control strategy and dead zone compensation strategy are adopted to effectively ensure the quality of power delivered from converter to grid;

• Compatible with various industrial fieldbus communication interfaces, such as CANopen and Profibus;

• Identical IGBT converter bridge modules are connected in parallel, and installation and removal of each power module is made convenient;

• Elaborately designed filtering system and a harmonics restraint control strategy ensure the superior quality of power delivered to the grid;

• This product can withstand high/low temperatures and high humidity. All circuit boards are equipped with anti- corrosion coating and all cabinets have very high protection class.