What are the key considerations for photovoltaic transformer selection?

Echo

06/27/2025

As an expert in the application and trends of electrical equipment, I have a profound mastery of knowledge in circuits, power electronics, etc. I possess a comprehensive set of abilities including equipment design, fault diagnosis, and project management. I can precisely grasp the industry's pulse and lead the development of the electrical field.

What aspects need attention during the installation of dry-type transformers?

1 Pre - installation PreparationAs a front - line installer, I know very well that the preparation work before installing a dry - type transformer must be thorough. First, I will carefully review the design drawings and technical documents, and check one by one the technical parameters such as the model specification, rated capacity, and voltage level of the transformer to ensure they are in full compliance with the design requirements. Then, I will conduct an unpacking inspection of the transfo

James

07/01/2025

What is included in the operational procedures of a smart electricity meter load switch?

As a frontline operator who deals with smart electricity meters daily, I’m well - versed in the design and operational norms of load switches (both internal and external) in these meters. Below, I’ll break down the technical requirements and practical key points based on my on - site experience for easy reference.I. Basic Understanding of Internal and External Load SwitchesIn the type specifications for single - phase and three - phase smart electricity meters (such as environmental

James

06/28/2025

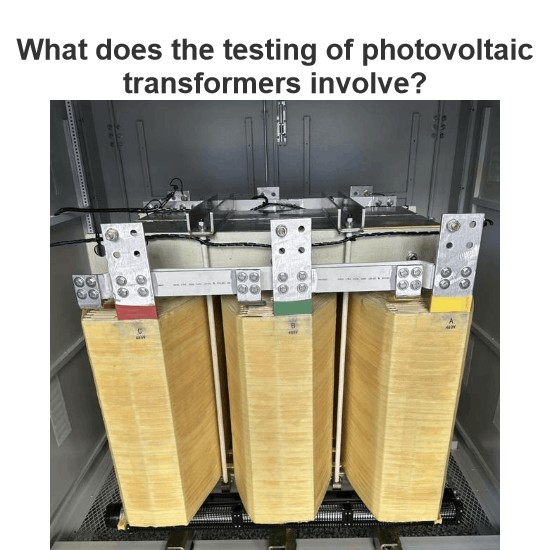

What does the testing of photovoltaic transformers involve?

1. Specificities and Testing Requirements of Photovoltaic TransformersAs a new energy systems technician, I recognize photovoltaic transformers' unique design and application traits: Inverter - output AC carries abundant 5th/7th - order odd harmonics, with PCC harmonic current distortion reaching 1.8% (higher voltage distortion under low load), causing winding overheating and accelerated insulation aging. Photovoltaic systems use TN - S grounding, requiring reliable N - phase output from the sec

Oliver Watts

06/27/2025

What are the advantages of split - winding transformers in grid - connected photovoltaic power stations?

Solar energy, as a clean and renewable energy source, is a key new energy supported in China. It has abundant theoretical reserves (17,000 billion tons of standard coal equivalent annually) and enormous development potential. Photovoltaic power generation, once mainly operating off - grid in remote areas, is now rapidly evolving towards building - integrated photovoltaics and large - scale desert - based grid - connected projects.This paper analyzes split - winding transformers in grid - connect

Echo

06/25/2025