1. Introduction

In the modern power grid infrastructure, high - voltage reclosers play a pivotal role in enhancing the reliability and efficiency of power supply. This is particularly crucial in regions like Indonesia, which has a vast and complex power distribution network spanning numerous islands, and Vietnam, with its developing coastal power systems. The 20kV voltage level, falling within the medium - high - voltage range, is widely adopted in urban grids, industrial power supply, and certain high - voltage transmission lines due to its advantages in power transmission efficiency and cost - effectiveness.

2. Function and Significance of High - Voltage Reclosers

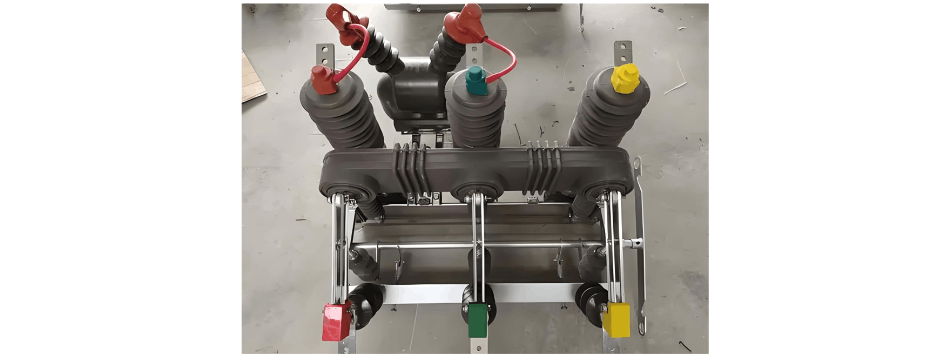

A high - voltage recloser is an intelligent switchgear used in power distribution network automation. It has the "self - contained" ability to detect fault currents, interrupt them within a given time, and perform a specified number of reclosures. When a short - circuit fault occurs in the line, the recloser operates to open and reclose according to a pre - set sequence and time interval. In the case of a permanent fault, after completing the pre - determined operation sequence and if the reclosure fails, it will lock in the open - circuit state, isolating the faulty section. Once the fault is resolved, manual reset is usually required to release the lock. For transient faults, the subsequent opening and closing operations will be terminated as soon as any reclosure is successful, and after a certain delay, it will return to the initial set state, preparing for the next potential fault.

In Indonesia, with its large - scale power grid covering a wide area, high - voltage reclosers are essential for quickly restoring power supply after faults, reducing power outage time, and improving the overall reliability of power supply. Similarly, in Vietnam's coastal areas, where environmental factors such as humidity and salt - fog can pose challenges to the power grid, reclosers help maintain stable power supply.

3. Design Considerations for 20kV High - Voltage Reclosers

3.1 Electrical Performance Design

3.1.1 Rated Voltage and Current

For 20kV reclosers, the rated voltage is designed to be 20kV to match the grid voltage level. The rated current needs to be determined based on the actual load current in the power grid section where it is installed. In industrial areas of Indonesia or Vietnam with high - power equipment, a higher - rated current recloser may be required to ensure normal operation under heavy - load conditions.

3.1.2 Fault - Breaking Capacity

The recloser must have sufficient fault - breaking capacity to interrupt large - magnitude short - circuit currents. In a 20kV system, short - circuit currents can reach several kilo - amperes. The design should consider the worst - case short - circuit scenarios in the local power grid, such as three - phase short - circuits near the power source. For example, in a typical 20kV industrial distribution network in Indonesia, the short - circuit current may be around 20 - 30kA, so the recloser should be designed to break such currents safely and reliably.

3.2 Mechanical Design

3.2.1 Operating Mechanism

The operating mechanism of the recloser should be highly reliable and capable of withstanding frequent operations. Spring - type or permanent - magnet - type operating mechanisms are commonly used. In the harsh environmental conditions of Vietnam's coastal areas, a well - sealed and corrosion - resistant permanent - magnet operating mechanism may be preferred. It can ensure stable operation even in the presence of salt - fog and high humidity, reducing the risk of mechanical failures due to corrosion.

3.2.2 Contact System

The contact system of the recloser is crucial for its performance. High - quality contact materials with good electrical conductivity and anti - arcing properties are selected. For 20kV reclosers, materials like copper - tungsten alloys are often used. The contact design should ensure good contact pressure to minimize contact resistance and prevent overheating during normal operation. Additionally, the contact system should be able to withstand the high - energy arcs generated during fault - breaking operations, with a long service life.

3.3 Insulation Design

3.3.1 Insulation Materials

In 20kV reclosers, appropriate insulation materials are selected based on the operating environment. In Indonesia's tropical climate with high humidity, materials with excellent moisture - resistant insulation properties, such as epoxy resin, are widely used. Epoxy - resin - based insulation can effectively prevent electrical breakdown caused by moisture absorption. In Vietnam's coastal areas, considering the additional factor of salt - fog, special anti - salt - fog insulation coatings may be applied to the insulation materials to further enhance their insulation performance.

3.3.2 Insulation Structure

The insulation structure of the recloser is designed to ensure sufficient electrical insulation distance and withstand the rated voltage and transient over - voltages. For example, the design of the insulation between the live parts and the grounded parts should comply with relevant international and national standards. In Indonesia, the recloser design should meet the requirements of the SNI 04 - 0225 standard, which specifies the minimum insulation distances and withstand voltage levels for high - voltage electrical equipment.

4. Standards Compliance: IEC 60068 - 2 - 52 and SNI 04 - 0225

4.1 IEC 60068 - 2 - 52

The IEC 60068 - 2 - 52 standard is relevant for reclosers in terms of environmental testing. In the context of Vietnam's coastal areas, reclosers need to meet the requirements of this standard regarding resistance to salt - fog corrosion. This standard stipulates specific test methods and acceptance criteria for equipment exposed to salt - fog environments. For example, reclosers are required to undergo a certain period of salt - fog spraying tests, and after the test, their electrical and mechanical performance should still meet the specified requirements. Compliance with this standard ensures that the reclosers can operate reliably in the harsh coastal environment of Vietnam.

4.2 SNI 04 - 0225

In Indonesia, the SNI 04 - 0225 standard is of great significance for high - voltage electrical equipment, including reclosers. This standard covers aspects such as electrical safety, insulation requirements, and mechanical performance. Reclosers designed for the Indonesian market must comply with the voltage - withstand test requirements specified in this standard. For instance, the insulation of the recloser should be able to withstand the specified AC and DC voltage tests without breakdown, ensuring the safety of personnel and equipment in the power grid.

5. Special Requirements for Reclosers in Indonesia and Vietnam

5.1 Indonesia

5.1.1 Island - based Power Grid

Indonesia's power grid is characterized by its vast expanse across numerous islands. Reclosers need to be designed for easy installation and maintenance in remote island areas. Compact - sized reclosers with self - contained operation and control systems are preferred. These reclosers can be easily transported to islands and installed on poles or in small substations. Additionally, due to the often - limited power supply capacity on some islands, reclosers should be able to operate efficiently with relatively low - power auxiliary power sources.

5.1.2 Tropical Climate

The tropical climate in Indonesia, with high temperatures and humidity throughout the year, poses challenges to the performance of reclosers. The recloser design should incorporate effective heat - dissipation measures. For example, using heat - conducting materials in the enclosure and designing proper ventilation channels to prevent overheating of internal components. Moreover, the selection of materials should consider their resistance to humidity - induced corrosion to ensure a long service life.

5.2 Vietnam (Coastal Areas)

5.2.1 Salt - fog and Humidity

In Vietnam's coastal areas, the high concentration of salt - fog in the air and high humidity levels are major concerns. Reclosers need to be highly resistant to salt - fog corrosion. As mentioned earlier, compliance with standards like IEC 60068 - 2 - 52 helps in this regard. In addition to using corrosion - resistant materials, the recloser enclosure should have a high - level of protection, such as an IP68 - rated enclosure. An IP68 - rated recloser in Vietnam's coastal areas can prevent the ingress of salt - water and dust, ensuring reliable operation even in the harshest coastal conditions.

5.2.2 High - Wind and Storm Conditions

Coastal areas in Vietnam are also prone to high - wind and storm events. Reclosers should be designed to withstand strong winds. Their installation structures need to be robust, and the enclosure should be able to resist the impact of flying debris during storms. For example, the recloser can be installed on a sturdy pole with proper guy - wires, and the enclosure should be made of impact - resistant materials.

6. Conclusion

The design of high - voltage reclosers for 20kV systems in Indonesia and Vietnam, especially in Vietnam's coastal areas, requires careful consideration of various factors. From electrical and mechanical performance to insulation design, and compliance with international and national standards such as IEC 60068 - 2 - 52 and SNI 04 - 0225. Meeting the specific environmental and power grid requirements of these regions, such as the island - based power grid and tropical climate in Indonesia, and salt - fog, humidity, high - wind conditions in Vietnam's coastal areas, is essential for ensuring the reliable operation of the power grid. Well - designed reclosers can significantly improve the power supply reliability, reduce power outage time, and support the stable development of the power industry in these regions. As the power demands in Indonesia and Vietnam continue to grow, continuous innovation and improvement in recloser design will be crucial to meet the future challenges of power grid operation.