Research on the Application of Prefabricated Optical and Electrical Hybrid Cables in Smart Substations

Echo

04/26/2025

At present, in order to rationally enhance the efficiency and effectiveness of the engineering construction phase, deeply apply various design achievements in the application phase, promote the concept of full lifecycle management, comprehensively apply various new modern technologies, establish a unified and centralized equipment management interface, and improve the efficiency of intensive engineering in the design and construction stages, State Grid Corporation of China has started to implement the design and construction of substations in a standardized distribution mode.

One of the main objectives is to standardize the parameters and interface standards of equipment, enabling primary equipment to be connected to secondary equipment, and secondary equipment to be connected to each other in a standardized manner. This ensures that secondary wiring is plug-and-play, providing more convenient services for tasks such as equipment bidding, operation and maintenance, and engineering design, while also reasonably reducing the engineering construction time. Based on this, in intelligent substations, in-depth research and analysis have been carried out on the application of prefabricated optical-electrical hybrid cables, which holds extremely important practical significance in the current situation.

1. Analysis of the Applicable Scope of Prefabricated Optical-Electrical Hybrid Cables in the Application Phase

In the modern context, the wiring methods used for the terminal blocks in traditional switchboards and fiber optic distribution boxes in substations during the connection process can no longer meet the new requirements of prefabricated substations in the installation and operation stages. At the same time, during the construction of intelligent substations, since tasks such as on-site cable and optical cable wiring, circuit connection, and circuit debugging are required when connecting the cables and optical cables inside the cabinets, the engineering construction period is relatively long.

This not only leads to low construction efficiency and relatively low reliability but also results in certain differences in the placement, installation, and wiring methods of the connection devices inside each cabinet. Therefore, the application of process technologies during the construction phase is extremely difficult, which invisibly increases the work cost in the maintenance phase and leads to generally low work efficiency in the construction debugging and subsequent maintenance phases.

Given this situation, considering comprehensively, the application of prefabricated optical-electrical hybrid cables, which have the advantages of quick plugging and unplugging, long service life, low density,small size, and high reliability, can better meet the new requirements of equipment in intelligent substations for plug-and-play functionality in the new era.

Research on the Application of Prefabricated Optical-Electrical Hybrid Cables in Intelligent Substations

Generally, prefabricated cables are suitable for the positions between the main body of high-voltage primary equipment and intelligent control cabinets. For intelligent substations using GIS (Geographic Information System) equipment, double-ended prefabricated cables can be selected for the connections between the circuit breakers inside the GIS main body and the intelligent control cabinets, between the disconnectors and the intelligent control cabinets, between the grounding switch mechanism boxes and the intelligent control cabinets, and between the main transformer terminal boxes and the intelligent control cabinets of the main transformer.

As for the connection method at both ends, aviation plug connectors can be selected for connection, and prefabricated matching sockets can be used at both ends. Then, according to the principles of separating dual-loop circuits, separating strong and weak currents, and separating AC and DC currents, a reasonable configuration can be carried out.After the application of prefabricated cables, the process level of the components inside the equipment during assembly will be enhanced. This can not only save the space inside the switchboards but also enable more convenient, rapid, and efficient installation on the construction site.

When intelligent control cabinet equipment is connected to various bay-level devices such as network analysis instruments, fault oscillograph devices, main transformer protection devices, line measurement and control devices, and line protection devices, optical cables are mainly used. However, the construction process used for the installation of ordinary optical cables is more complex than that of cables, and the requirements for the installation environment during fiber optic fusion splicing are extremely high. Therefore, prefabricated optical cables with prefabricated connectors in the factory can be selected. During on-site construction, a fusion-free connection method can be used, which can minimize the optical attenuation and loss during the construction of the fiber optic fusion points and improve the reliability and stability of the fiber optic loop during connection.

2. Analysis of the Technical Characteristics of Prefabricated Optical-Electrical Hybrid Cables

Optical-electrical hybrid cables are cables that incorporate insulated conductors within the structure of optical cables, integrating power transmission copper wires and optical fibers into one. Since power transmission and optical cable transmission belong to two completely different types of transmission methods, there will be no interference between them during the transmission process. Optical-electrical hybrid cables not only possess the characteristics of ordinary optical cables but also comply with the relevant standards and specifications for low-voltage power transmission of cables. They can simultaneously address the issues existing in the transmission of optical and electrical signals of equipment.

In terms of the advantages of optical-electrical hybrid cables, they have the characteristics of occupying a small space, being lightweight, and having a small outer diameter. In most cases in the past, problems that required the use of multiple cables and optical cables to solve together can now be reasonably addressed by simply using one hybrid cable. At the same time, the application of optical-electrical hybrid cables also has the following advantages:

- During the transmission process, it can provide multiple different types of transmission technologies simultaneously. The equipment has strong expandability and good adaptability during application, and the product has a relatively wide coverage in terms of applicability.

- In terms of application performance, it has excellent internal pressure resistance and bendability, with relatively high superiority and a relatively high level of convenience during construction.

- Customers do not need to spend excessive costs during the procurement process, and the cost during construction is relatively low.

Since the hybrid cable is of the prefabricated type, during the initial design stage, it is necessary to accurately calculate and predict the actual laying length of the prefabricated optical cable to prevent, as much as possible, situations where the length does not meet the standard or exceeds the standard. At present, equipment manufacturers can provide prefabricated optical-electrical hybrid cables. The customization range of the number of cores in the optical cable is approximately 6 to 48 cores, and it can be selected as multimode or single mode. The types of armors are mostly copper or corrugated aluminum. The length can be prefabricated in advance, and various different types of electrical connectors or optical connectors can be selected for the connectors at both ends.

When selecting a distribution frame, it is recommended to use a modular optical-electrical hybrid distribution frame, which can flexibly and scientifically configure the ratio of optical fibers to copper according to the different differences of the user equipment ports, maximizing the satisfaction of various requirements in the power distribution management process.

According to the characteristics of optical-electrical hybrid cables, in an intelligent substation, the intelligent terminals of each bay can be uniformly combined into power loss alarm signals and unit optical signals, and transmitted to the bay protection, measurement, and control equipment using the same type of optical-electrical hybrid cable. When the AC and DC power supplies are connected from the AC and DC distribution panels of the switchgear factory, the wiring used for connecting the equipment across different floors and sites can be uniformly simplified into optical-electrical hybrid cables, enabling the realization of the idea that all control signals of a typical bay are connected using one cable .

3. Specific Case Analysis of the Application of Prefabricated Optical-Electrical Hybrid Cables

This article takes the typical bays on the 110 kV and 220 kV sides of a certain intelligent substation as the main cases. By comparing the specific situations of the application of prefabricated optical-electrical hybrid cables, it specifically elaborates on the main characteristics of the application of prefabricated optical-electrical hybrid cables as follows:

(1) Statistical Analysis of the Specifications and Quantities of Optical-Electrical Hybrid Cables on the 110 kV Side

Based on the double-busbar wiring mode on the 110 kV side and the use of GIS equipment for research, there is a single-set configuration in the integrated device of the intelligent terminal merging unit for the 110 kV power line and the sectionalization; there is a double-set configuration in the integrated device of the intelligent terminal merging unit for the 110 kV main transformer incoming line. Two bus voltage merging units are installed in the intelligent control positions of the busbar equipment.

The following mainly takes the 110 kV line bay as an example. By centrally analyzing the quantities of optical cables and cables between the intelligent control cabinet and the secondary equipment, the specifications and quantities of the optical-electrical hybrid cables on the 110 kV side are sorted out and analyzed.

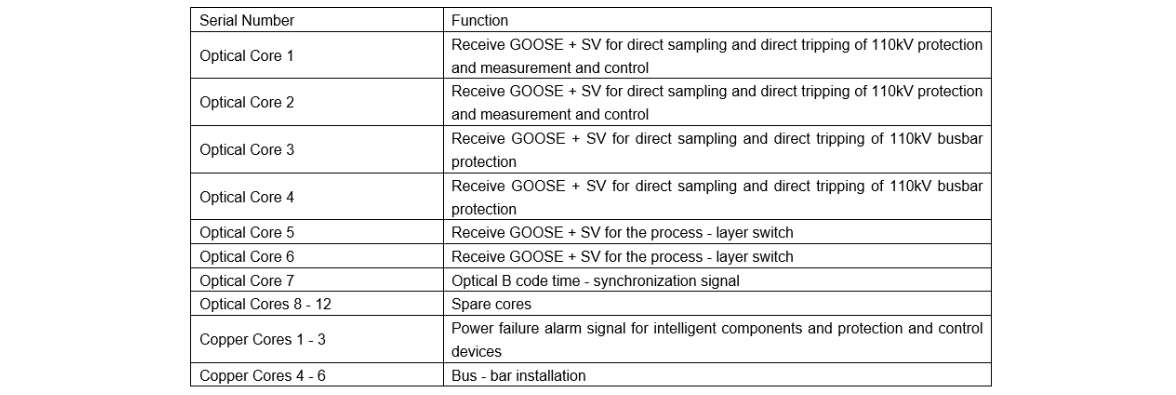

Table 1 Statistics of cable and optical cable coefficients in 110-kilovolt line intervals

As shown in Table 1, by centrally counting the number of optical fiber cores and cable cores from the process layer to the bay layer in the 110 kV line bay, and comprehensively considering the maximum demand and actual spare cores, a prefabricated optical - electrical hybrid cable composed of one 12 - core optical fiber plus 6×1.5 - sized copper wires is selected for the outgoing line and sectionalization bays. According to the dual - configuration of the main substation, two prefabricated optical - electrical hybrid cables, each composed of 12 - core optical fibers plus 6×1.5 - sized copper wires, are selected for the main intelligent control cabinet on the 110 kV side.

(2) Statistical Analysis of the Specifications and Quantities of Optical - Electrical Hybrid Cables on the 220 kV Side

Based on the double - busbar wiring mode on the 220 kV side and the use of GIS (Geographic Information System) equipment, the intelligent terminals and merging units are uniformly arranged in the intelligent control cabinet. The research on the configuration of the process layer and the bay layer is carried out using a dual - configuration method.

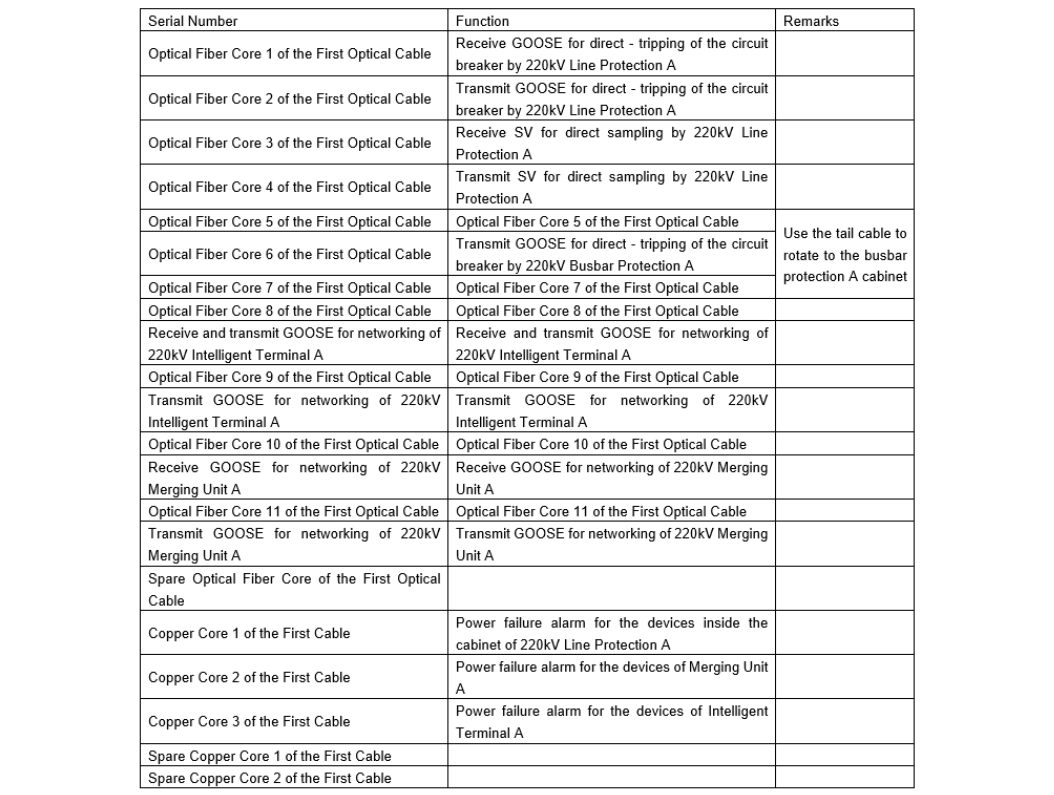

The following mainly takes the 220 kV line bay as a specific example. By statistically analyzing the quantities of optical cables and cables from the intelligent control cabinet to the secondary equipment room, the actual specifications and quantities of the 220 kV optical - electrical hybrid cables are sorted out and summarized.

Considering the dual - configuration on the 220 kV side, the number of cable cores and optical fiber cores of the second cable and its configuration are the same as those of the first cable. The specific content is shown in Table 2. By statistically analyzing the number of cable cores and optical fiber cores from the process layer to the bay layer in the 220 kV line bay, and systematically considering the maximum demand and spare cores, each intelligent control cabinet can use two prefabricated optical - electrical hybrid cables with a specification of 24 - core optical fibers plus 6×1.5 copper wires .

(3) Data Aggregation and Analysis of the Application of Optical - Electrical Hybrid Cables in Intelligent Substations

Based on the data from the above - mentioned statistical process, the analysis shows that in terms of specifications, the prefabricated optical - electrical hybrid cables used inside intelligent substations can be optimized into 24 - core optical cables + 6 - core cables and 12 - core optical cables + 6 - core cables.

The number of cables from the intelligent control cabinets on each side of the 220 kV and main substations to the secondary equipment room can be minimized to two, and the number of cables from the intelligent control cabinet on the 110 kV side to the secondary equipment room can be minimized to one.

As the cost of equipment materials in the investment process continues to decrease, a series of indirect economic benefits are generated, as follows:

- The process - oriented and streamlined levels of cable component assembly are higher, and the work efficiency in the construction process is higher. This can maximize the savings in labor and engineering time and reduce the cost of on - site installation and construction.

- After using prefabricated cables, it can specifically improve the standardization level of users, reduce the variety and quantity of materials, reasonably release the occupancy of the original inventory of users, and reduce the cost of management.

- It reduces the workload in the later operation and maintenance process, has better green and environmental protection performance, and is more in line with the overall requirements of the construction of "two - type and one - standardization" substations.

Table 2 Statistics of Cable Cores and optical cable Cores in 220-kilovolt line intervals

4. Conclusion

In summary, the application of prefabricated cables in intelligent substations aims to achieve standardized and regulated connections for optical cables and cables between primary and secondary equipment, as well as among secondary equipment. This can specifically enhance the construction efficiency and process quality of secondary equipment during the construction phase.

This article has mainly discussed the application scope and technical characteristics of prefabricated optical - electrical hybrid cables. It has studied and analyzed the specific application of optical - electrical hybrid cables in 220 kV intelligent substations, and summarized and analyzed several common standard interfaces of hybrid cables used in 220 kV substations.

The use of prefabricated optical - electrical hybrid cables can organically integrate cables and optical cables. It can specifically reduce the laying workload at the construction site, decrease the cross - sectional size of cable trenches and the actual occupied area, and effectively cut down the project cost throughout the entire project cycle of intelligent substations.

The research content in this article mainly focuses on how to use optical-electrical hybrid cables to replace prefabricated optical cables for connecting secondary equipment between switchboards across different sites and in areas such as across rooms .

As an expert in the application and trends of electrical equipment, I have a profound mastery of knowledge in circuits, power electronics, etc. I possess a comprehensive set of abilities including equipment design, fault diagnosis, and project management. I can precisely grasp the industry's pulse and lead the development of the electrical field.