What are the key features of a paper insulated copper cable?

Main Features of Paper-Insulated Copper Cable (PCC)

1. Excellent Electrical Performance

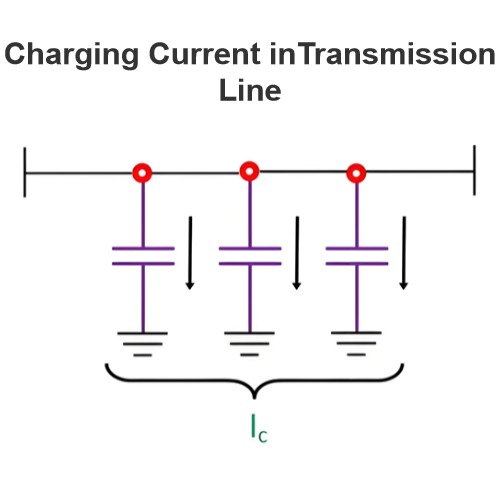

High Insulation Strength: The paper insulation, when impregnated with insulating oil, provides excellent insulation strength, making it suitable for high-voltage and ultra-high-voltage transmission systems.

Low Dielectric Loss: The dielectric loss tangent of the paper insulation is low, reducing energy losses and improving transmission efficiency.

Good Heat Resistance: The paper insulation maintains stable electrical properties at higher temperatures, ensuring reliable operation over long periods.

2. Superior Mechanical Properties

Good Flexibility: Paper-insulated copper cables are flexible, making them easy to install in complex environments and allowing for bending without damage.

High Tensile Strength: Copper conductors have high tensile strength, enabling the cable to withstand significant mechanical stress, suitable for long-distance overhead or underground installations.

Strong Corrosion Resistance: Copper conductors exhibit excellent corrosion resistance, especially in humid or corrosive environments, extending the cable's service life.

3. Excellent Thermal Stability

Heat Resistance: The paper insulation, after special treatment, can operate stably at high temperatures, typically up to 90°C or higher.

Good Heat Dissipation: The high thermal conductivity of copper allows heat to be efficiently dissipated from the cable's interior to the exterior, preventing overheating and ensuring safe operation.

4. Long Service Life

Extended Lifespan: Paper-insulated copper cables can last several decades or longer, particularly with proper maintenance. Their durability and reliability make them a preferred choice for many power systems.

Slow Aging: The paper insulation, when impregnated with oil, ages slowly, maintaining good insulation properties over time.

5. Cost-Effective

High Cost-Benefit Ratio: Although the initial investment for paper-insulated copper cables may be higher, their long lifespan and low maintenance costs result in lower overall ownership costs, offering good economic value.

Recyclable Materials: Both the copper conductor and paper insulation are recyclable, aligning with environmental sustainability goals and reducing resource waste.

6. Wide Range of Applications

High-Voltage and Ultra-High-Voltage Transmission: Paper-insulated copper cables are widely used in high-voltage (e.g., 110kV, 220kV) and ultra-high-voltage (e.g., 500kV and above) transmission systems, especially for long-distance power transmission.

Underground and Overhead Installations: These cables are suitable for both underground and overhead applications, adapting to various installation environments and requirements.

7. High Safety

Good Fire Resistance: The impregnated paper insulation has certain fire-resistant properties, maintaining cable integrity in case of fire and reducing safety hazards.

Low Leakage Risk: With its high insulation strength and low dielectric loss, paper-insulated copper cables have a very low risk of leakage, ensuring safe power transmission.

8. Easy Maintenance

Simple Inspection and Repair: The relatively simple structure of paper-insulated copper cables allows for easy inspection using conventional electrical testing methods. Potential issues can be detected and repaired promptly.

Accurate Fault Localization: In the event of a fault, partial discharge detection and other methods can accurately locate the fault point, facilitating quick repairs and minimizing downtime.

Summary

Paper-Insulated Copper Cables (PCC) are characterized by their excellent electrical performance, superior mechanical properties, thermal stability, long service life, cost-effectiveness, wide range of applications, high safety, and ease of maintenance. Despite advancements in modern cable technology, PCC remains widely used due to its reliability and durability, particularly in high-voltage and ultra-high-voltage transmission systems where long-term reliability is crucial.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.