Why are Electrical Busbars Rectangular Instead of Circular?

Why are Busbars Flat or Rectangular?

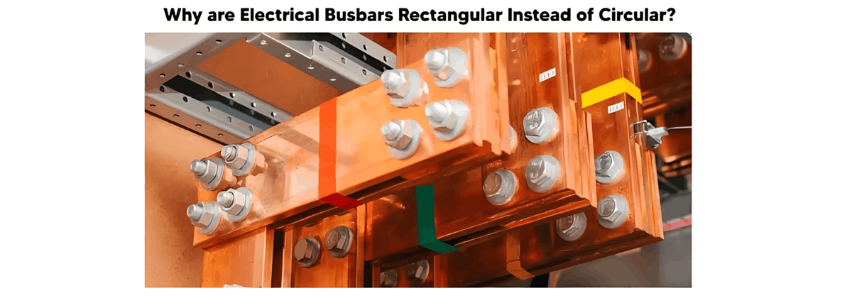

Unlike cables, which are often circular, busbars are predominantly flat or rectangular. This shape is not arbitrary; it offers several significant advantages. Firstly, the flat or rectangular form provides a larger surface area, which is essential for efficient heat dissipation and enhanced electrical conductivity. This increased surface area allows for better heat transfer to the surrounding environment, preventing overheating and ensuring the longevity of the busbar and connected equipment.

Secondly, the flat design simplifies the installation process. It allows for straightforward mounting and connection within electrical enclosures, reducing the complexity and time required for assembly. Additionally, the flat profile helps to minimize electrical losses by evenly distributing the current across the busbar's surface. This even current distribution is crucial for maintaining consistent electrical performance and preventing hotspots that could lead to failures.

Finally, the flat or rectangular shape of busbars enables the connection of multiple circuits with ease. Instead of requiring individual wiring for each circuit, busbars can accommodate multiple connections, streamlining the electrical system and reducing the amount of cabling needed. This not only saves space but also simplifies maintenance and troubleshooting, making busbars an ideal choice for power distribution applications.

Reasons for Designing Flat Busbars

The choice of flat or rectangular shapes for busbars over circular or other geometries is underpinned by several critical factors that enhance their performance, practicality, and cost - effectiveness in electrical systems:

1. Surface Area and Heat Dissipation

A rectangular cross - section offers a significantly larger surface area compared to a circular one of equivalent conductor size. This increased surface area is a key advantage for heat dissipation, which is paramount in high - current applications. In power distribution systems and other high - load environments where busbars are commonly used, overheating can not only shorten the lifespan of the busbar but also pose significant safety risks. By facilitating more efficient heat transfer to the surrounding environment, the rectangular shape ensures effective heat management, safeguarding the integrity and reliability of the electrical system.

2. Current - Carrying Capacity

The skin effect is a well - known phenomenon in alternating - current (AC) systems, where the current tends to concentrate near the surface of a conductor, particularly at higher frequencies, rather than flowing uniformly throughout its cross - section. Rectangular busbars mitigate the impact of the skin effect due to their relatively larger surface - to - cross - sectional - area ratio. This allows for improved current distribution, enabling rectangular busbars to carry more current than circular cables with the same cross - sectional area. Even in direct - current (DC) applications, where the skin effect is not a factor, the flat design promotes more uniform current flow, optimizing the busbar's performance.

3. Efficient Space Utilization

When installed within electrical panels, switchgear, or busbar trunks, rectangular busbars offer superior space - saving capabilities compared to circular conductors. Multiple flat busbars can be neatly stacked or closely arranged with insulation in between, making the most of the available space within compact electrical enclosures. This efficient space utilization is especially crucial in modern electrical systems, where equipment is often designed to be as compact as possible. Moreover, the ease of alignment and management of flat busbars simplifies the layout and installation process in large - scale electrical distribution networks.

4. Mechanical Stability

Flat, rectangular busbars exhibit greater rigidity and mechanical stability than circular cables. Under high - current conditions, this rigidity helps to minimize vibrations and movement, ensuring consistent and reliable operation over extended periods. In contrast, circular cables are more flexible, making them better suited for applications where movement or bending is necessary, such as in wiring systems. The enhanced mechanical stability of rectangular busbars contributes to their long - term durability and reduces the likelihood of mechanical failures.

5. Cost Efficiency

For specific applications, the manufacturing process of rectangular busbars can be optimized to achieve greater material efficiency. The shape allows manufacturers to make the most of copper or aluminum, reducing material waste and overall costs in large - scale installations. Additionally, the fabrication techniques for flat busbars, such as punching, cutting, and bending, are generally simpler compared to the more complex processes involved in producing round conductors and cables, such as drawing, extrusion, and intricate calculations. These factors combined result in lower overall manufacturing costs for rectangular busbars.

6. Ease of Connection and Installation

The flat surfaces of rectangular busbars simplify the connection process. Drilling holes for attaching other conductors or equipment is straightforward, and they can be terminated easily. Unlike round busbars, which may require specialized connectors or adapters for joints, bends, and tap connections, rectangular busbars can be securely bolted or clamped into place, streamlining the installation process and reducing the need for additional components.

While rectangular busbars offer numerous advantages, the selection of busbar shape ultimately depends on specific application requirements. For example, circular busbars may be preferred in situations involving extreme mechanical stresses, such as in high - voltage direct - current (HVDC) transmission systems. Nevertheless, for high - power electrical systems, rectangular busbars remain the top choice due to their exceptional heat dissipation, high current - carrying capacity, efficient space utilization, robust mechanical stability, and user - friendly installation characteristics.

Why Busbars are Preferred over Cables?

In numerous electrical systems, busbars have emerged as the favored choice over cables, primarily due to their exceptional performance in high - current scenarios, efficient space utilization, and simplified maintenance requirements. The flat and wide design of busbars endows them with a significantly larger surface area compared to cables. This enhanced surface area facilitates superior heat dissipation, effectively reducing the risk of overheating that is often associated with bundled cables. As a result, busbars can operate more reliably and safely in demanding electrical environments.

One of the key advantages of busbars lies in their power distribution capabilities. A busbar chamber offers a streamlined and straightforward method for channeling incoming power to multiple distribution boards and panels. Unlike cables, which often require numerous joints and connections, busbars eliminate much of this complexity. This simplicity makes tapping and terminating busbars a far easier task, especially within intricate power distribution circuits. The reduced need for multiple joints also minimizes potential points of failure and reduces the associated labor and material costs.

Busbars are engineered to handle higher currents with lower impedance, a crucial factor in electrical systems. This characteristic results in a reduced voltage drop over long distances, ensuring a more stable and consistent power supply. Their rigid structure provides greater mechanical strength, enabling them to withstand environmental and physical stresses with ease. This durability not only extends the lifespan of the busbars but also reduces the frequency of replacements and maintenance interventions, contributing to overall cost - savings in the long run.

In terms of design flexibility, busbars offer significant advantages. They are highly adaptable, allowing for modular expansion as electrical systems grow and evolve. This modularity makes them an ideal choice for compact spaces, such as electrical switchgear and industrial power distribution systems, where space optimization is crucial. Additionally, busbars can safely handle higher fault currents during short - circuit events. Their ability to manage these surges effectively enhances the overall safety and reliability of the electrical system, protecting connected equipment and minimizing the risk of damage or disruption.

When considering the cumulative benefits of superior heat management, simplified power distribution, efficient current - carrying capacity, robust mechanical strength, and design flexibility, it becomes clear that busbars represent a more efficient, scalable, and organized solution for electrical power distribution. These qualities make them the preferred option over traditional cabling systems, particularly in high - power applications where performance, reliability, and ease of maintenance are of utmost importance.