Definition

A Platinum Thermal Resistance (PTR), also known as a Platinum Resistance Thermometer (PRT), utilizes platinum as the sensing material to measure temperature. Its operation is grounded in the principle that the electrical resistance of platinum varies predictably with temperature changes. This type of thermometer is capable of accurately measuring temperatures within a wide range, from -200°C to 1200°C.

Platinum, an inert metal, possesses excellent malleability, allowing it to be easily drawn into fine, uniform wires. These unique properties—chemical stability and consistent resistance - temperature characteristics—make platinum an ideal choice for use as the sensing element in thermometers, ensuring reliable and precise temperature measurements across diverse applications.

How Platinum Resistance Thermometers Work

The resistance of platinum exhibits a near-linear relationship with temperature, a fundamental property harnessed for accurate temperature measurement. To determine the resistance value, an alternating or direct current is passed through the platinum element. As current flows, a voltage drop is induced across the metal, which can be precisely measured using a voltmeter. Leveraging a pre-established calibration equation, the measured voltage reading is then converted into a corresponding temperature value, enabling accurate temperature determination.

Construction of Platinum Resistance Thermometers

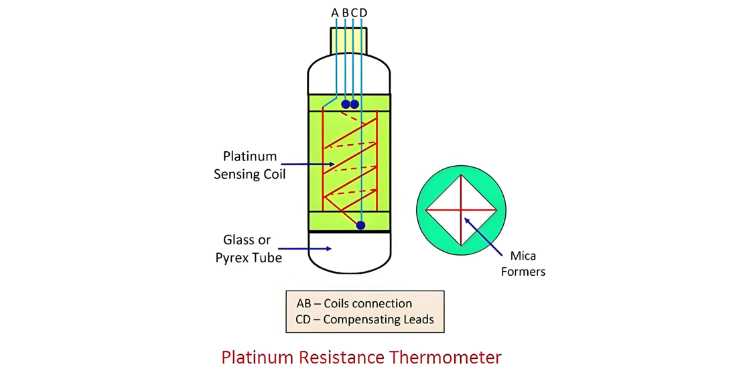

The diagram below illustrates the structure of a typical platinum resistance thermometer. At its core, the platinum sensing coil is encased within a protective bulb, commonly fabricated from glass or Pyrex. These materials provide thermal stability and electrical insulation, safeguarding the integrity of the sensing element. Additionally, an insulating layer deposited on the surface of the glass tube further enhances the thermometer's performance, contributing to accurate and consistent temperature sensing.

Structural Details of Platinum Resistance Thermometers (PTRs)

In a PTR, a double-strand platinum wire is wound around a mica strip. This dual-wire configuration minimizes inductive effects caused by alternating current, ensuring measurement accuracy. The mica strip, acting as an electrical insulator, is positioned at the ends of the tube to secure the coil and prevent short circuits.

An ebonite cap seals the open end of the tube, providing mechanical stability and insulation. The platinum wire’s terminals are connected to thick copper leads, which in turn attach to terminals (labeled AB) embedded in the ebonite cap. To counteract the resistance of the copper wires and improve precision, two identical copper wires (called compensating leads, labeled CD) are connected to the upper-end terminals. This “four-wire” arrangement eliminates errors caused by lead wire resistance, a critical feature in high-accuracy applications.

Industrial-Grade PTR Design

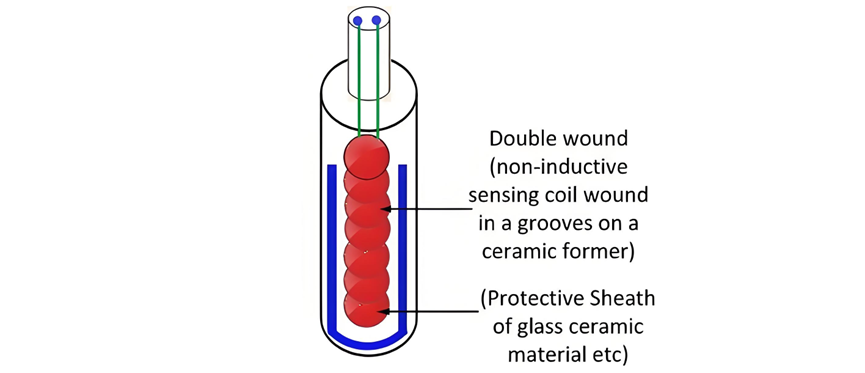

The figure below depicts an industrial platinum resistance thermometer. Here, the platinum sensing coil is safeguarded by a stainless steel sheath or a glass/ceramic coating. This dual-layer sealing offers two key benefits:

- Mechanical Strength: The robust casing protects the fragile platinum wire from physical damage in harsh industrial environments.

- Chemical Resistance: The glass or ceramic sealant shields the sensing element from corrosive substances, ensuring long-term reliability and accuracy in chemically aggressive settings.

This design balances durability with measurement precision, making platinum resistance thermometers suitable for applications ranging from laboratory research to high-temperature industrial processes.

Advantages of Platinum Resistance Thermometers

- Ease of Use: Temperature measurement with a platinum resistance thermometer is more straightforward compared to gas thermometers, requiring less complex setup and maintenance.

- High Precision: The meter delivers highly accurate temperature readings, making it ideal for applications demanding precision, such as calibration labs or industrial quality control.

- Wide Temperature Range: It operates effectively across a broad temperature spectrum, from -200°C to 1200°C, accommodating diverse environments from cryogenic to high-temperature settings.

- Sensitivity: The thermometer exhibits excellent sensitivity to subtle temperature changes, ensuring reliable detection of even minor fluctuations.

- Reproducibility: Platinum’s resistance-to-temperature relationship is highly consistent. For a given temperature, platinum consistently exhibits the same resistance value, ensuring repeatable measurements.

Disadvantages of Platinum Resistance Thermometers

- Slow Response Time: The thermometer has a relatively sluggish response to rapid temperature changes, limiting its suitability for applications requiring real-time tracking of fast dynamics.

- Upper Temperature Limitations:

- While platinum has a high melting point (~1768°C), prolonged exposure to temperatures above 1200°C causes the metal to gradually evaporate, compromising the sensor’s integrity and accuracy over time.

- This restricts its use in extremely high-temperature environments beyond its recommended operational range.

- Sensitivity to Construction Quality: Achieving excellent sensitivity and a wide measurement range relies heavily on meticulous manufacturing. Poorly constructed units may exhibit reduced performance or reliability, necessitating careful calibration and maintenance.

Key Considerations

Despite its limitations, the platinum resistance thermometer remains a preferred choice in many fields due to its unmatched stability, precision, and broad temperature range. For applications requiring ultra-high temperatures or rapid response, alternative sensors (e.g., thermocouples) may be more suitable, but PTRs excel in scenarios demanding consistency and long-term reliability.