Electromagnetic Flow Meter

Definition of Electromagnetic Flow Meter

An electromagnetic flow meter is a device used to measure the flow of liquid as it passes through a pipeline. More specifically, electromagnetic flow meters are used to measure the flow rate of electrically conducting fluids. An electrically conductive liquid refers to any liquid that allows an electric current to pass through it.

Working Principle of Electromagnetic Flow Meter

Electromagnetic flow meters operate based on Faraday's Law of electromagnetic induction. This law states that when a conductive liquid passes through a magnetic field, a voltage is induced across the conductor. The magnitude of this induced voltage is directly proportional to the velocity of the fluid, the length of the conductor (i.e., the distance the fluid travels through the magnetic field), and the strength of the magnetic field.

Detailed Explanation of the Working Principle

Electromagnetic flow meters do not create an obstruction in the path of the liquid to induce voltage; instead, they utilize Faraday's Law of electromagnetic induction. As the electrically conductive fluid flows through the magnetic field generated by the flow meter, a voltage is induced perpendicular to both the direction of flow and the magnetic field. This induced voltage is then detected by electrodes within the flow meter and converted into a measurement of flow rate. Since the induced voltage is directly related to the fluid velocity, measuring this voltage allows for precise determination of the flow rate.

In this way, electromagnetic flow meters provide non-invasive, highly accurate measurements of fluid flow without requiring any physical alterations to the pipeline. This characteristic makes electromagnetic flow meters an invaluable tool in many industrial applications, particularly when dealing with corrosive or high-purity fluids.

The above content has been refined to enhance clarity and readability while ensuring accurate conveyance of the working principle and importance of electromagnetic flow meters. Note that in practical applications, appropriate models and technical parameters should be selected based on specific needs.

Construction of Electromagnetic Flow Meter

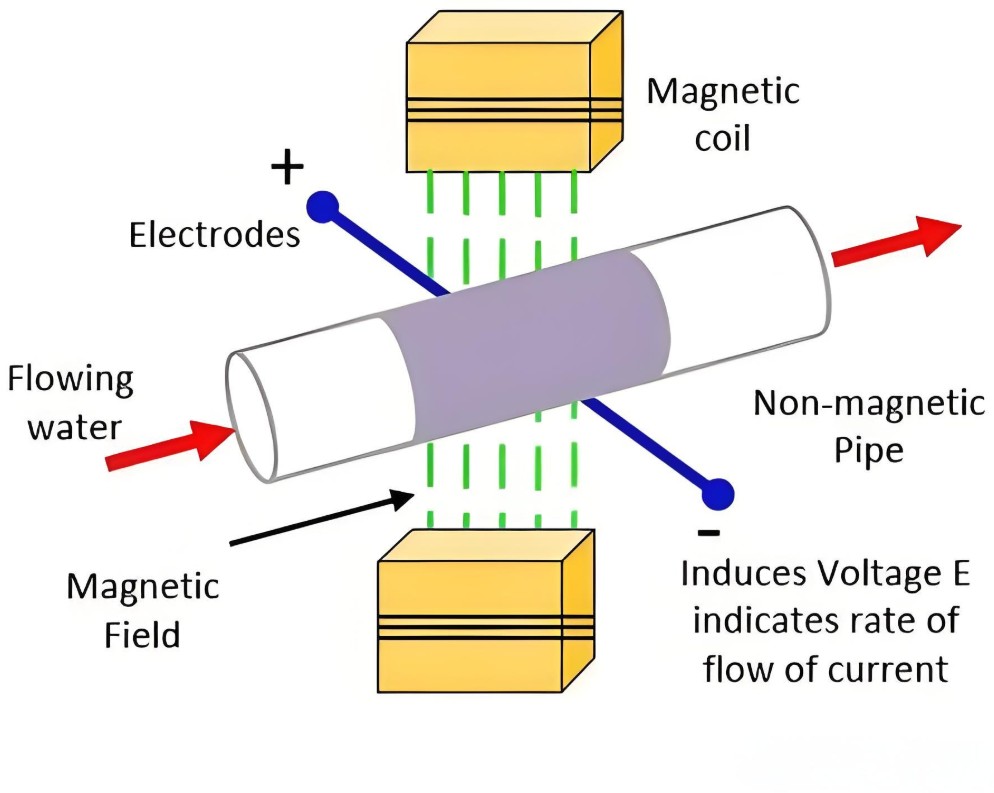

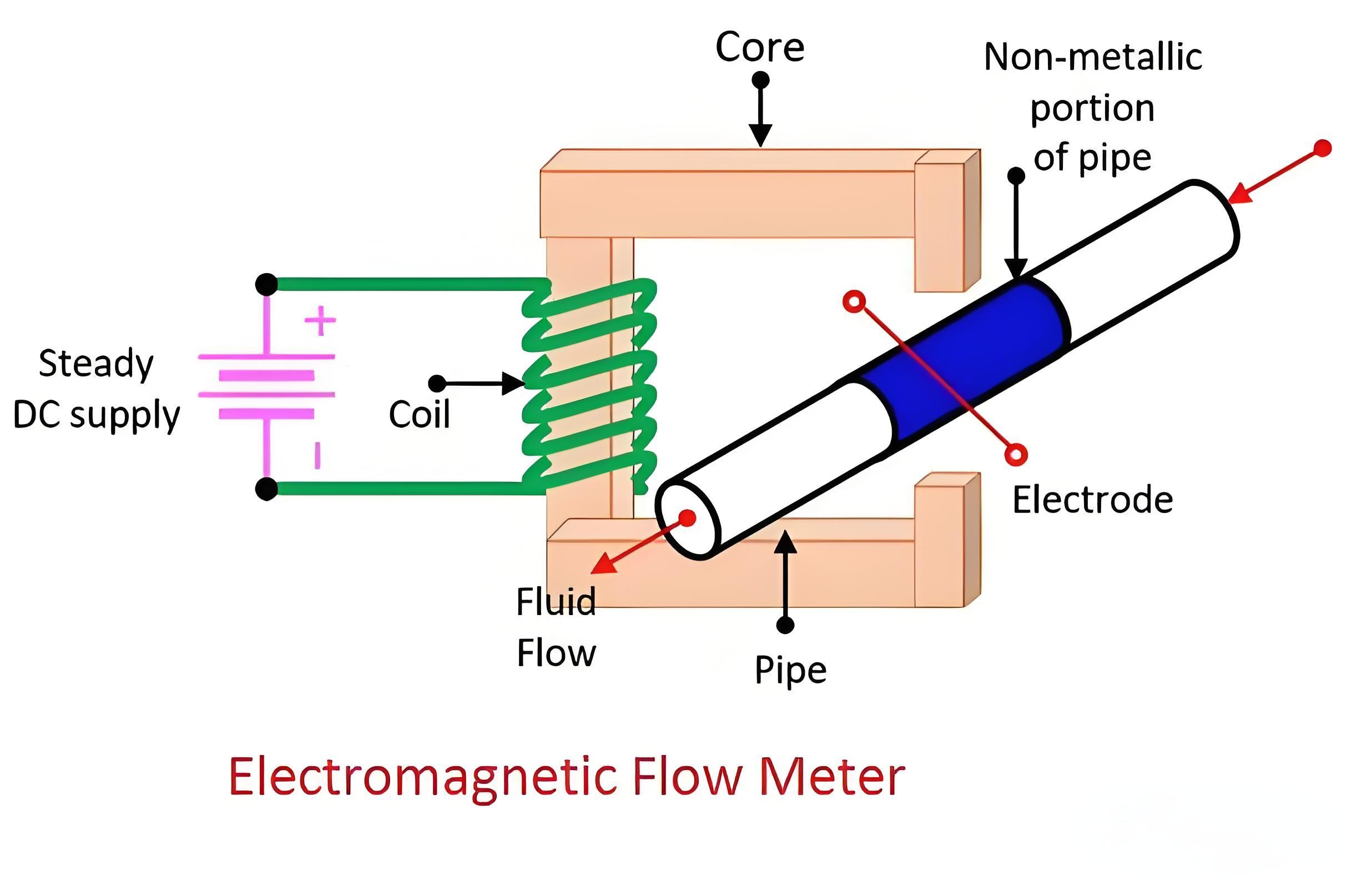

The electromagnetic flow meter primarily consists of an electrically insulated pipe, a pair of electrodes placed opposite to each other, and magnetic coils positioned around the pipe for generating the magnetic field. The electrically insulated pipe, typically made from non-conductive materials such as fiberglass, carries the liquid whose flow rate needs to be measured.

Electrically Insulated Pipe: This pipe is made from electrically insulating materials to ensure that the liquid passing through it can be accurately measured without interference from external electrical influences.

Electrodes: Two electrodes are mounted opposite each other on the pipe. Their function is to detect the induced voltage generated as the liquid flows through the magnetic field. These electrodes come into direct contact with the flowing liquid and transmit the detected voltage signals to a converter for processing.

Magnetic Coils: Magnetic coils are wrapped around the pipe. When current passes through these coils, they generate a magnetic field perpendicular to the direction of liquid flow. This magnetic field is crucial for inducing the voltage according to Faraday's Law of electromagnetic induction, which is proportional to the velocity of the fluid.

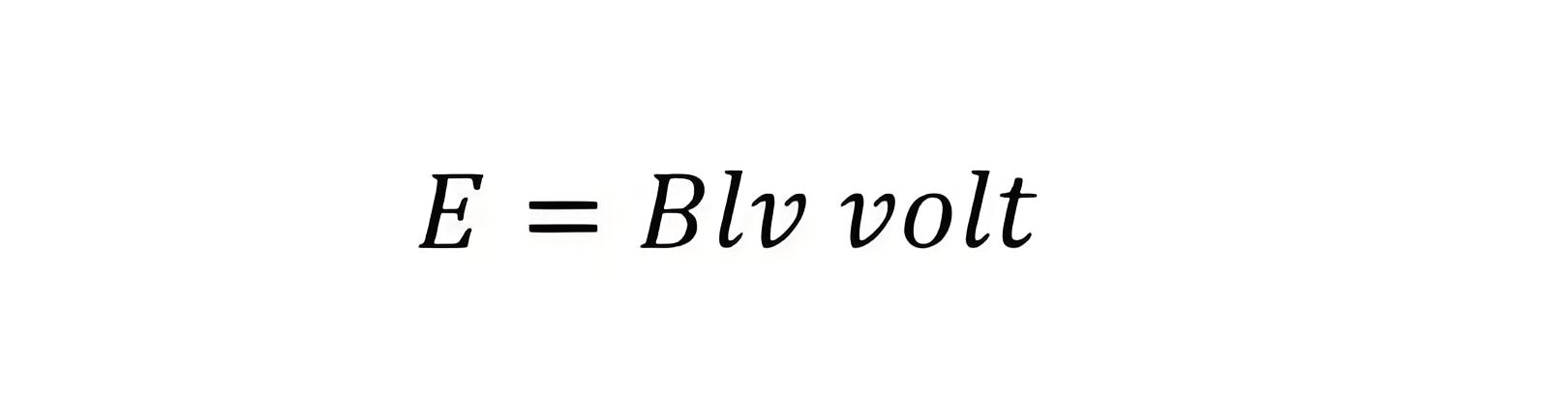

An electromagnet is positioned around an insulated pipe, generating a magnetic field in its vicinity. This setup is analogous to a conductor in motion within a magnetic field. As the liquid flows through the pipe, a voltage is induced across the coil, which can be expressed as follows.

v represents the velocity of the conductor (equivalent to the flow velocity), measured in meters per second (m/s).

l is the length of the conductor, which is equal to the diameter of the pipe, measured in meters (m).

Bdenotes the magnetic flux density, with the unit webers per square meter (wb/m²).

When the magnetic field around the pipe stays constant, the induced voltage is directly proportional to the velocity of the fluid.

Advantages of Electromagnetic Flow Meters

The output voltage of an electromagnetic flow meter is proportional to the liquid's flow rate.

The output remains unaffected by variations in liquid properties such as viscosity, pressure, and temperature.

These flow meters are capable of measuring the flow of slurries and greasy substances, and can handle corrosive fluids.

They can function as bidirectional meters.

Electromagnetic flow meters are also able to measure extremely low flow rates.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.