What is the method for determining the temperature of a coil?

Methods to Determine Coil Temperature

There are several methods to determine coil temperature, and the choice depends on the application scenario, required accuracy, and available equipment and technology. Below are some commonly used methods to determine coil temperature:

1. Direct Measurement Methods

a. Thermocouples

Principle: Thermocouples utilize the thermoelectric effect produced by the contact of two different metal materials to measure temperature.

Usage: Install the thermocouple probe near or within the coil. Connect it to a temperature reading device to monitor temperature changes in real-time.

Advantages: Fast response time, suitable for high-temperature environments.

Disadvantages: Requires physical contact, which may affect normal coil operation; complex installation.

b. Resistance Temperature Detectors (RTDs)

Principle: RTDs measure temperature based on the characteristic that the resistance of metals changes with temperature.

Usage: Install the RTD sensor near or within the coil and measure its resistance to calculate temperature.

Advantages: High accuracy and stability.

Disadvantages: Slower response time compared to thermocouples; higher cost.

c. Infrared Thermometers

Principle: Infrared thermometers measure surface temperature by detecting the infrared radiation emitted by an object.

Usage: Non-contact measurement; simply aim the thermometer at the target area to take a reading.

Advantages: Non-contact, suitable for hard-to-reach or moving objects.

Disadvantages: Affected by environmental factors such as dust and humidity; relatively lower accuracy compared to direct contact methods.

2. Indirect Measurement Methods

a. Copper Loss Method

Principle: Estimate temperature based on changes in current and resistance within the coil. Copper losses (I²R) increase with temperature because conductor resistance increases with temperature.

Usage:

Measure the DC resistance of the coil in a cold state.

During operation, measure current and voltage to calculate copper losses.

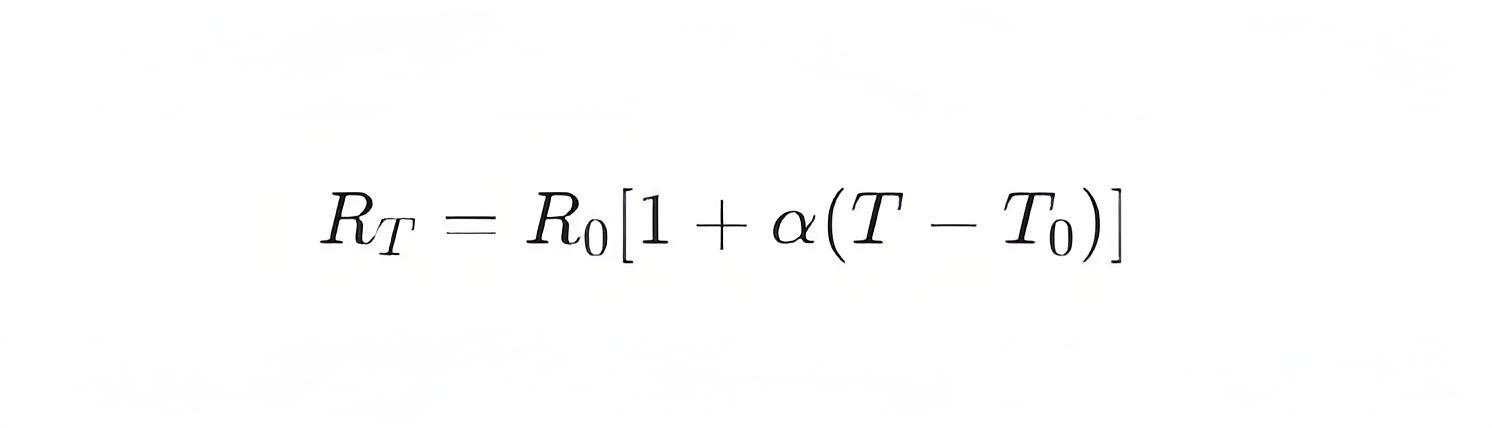

Use the resistance temperature coefficient (α) formula to calculate temperature changes:

where RT is the resistance during operation, R0 is the resistance in the cold state, α is the resistance temperature coefficient, T is the operating temperature, and T0 is the cold-state temperature.

Advantages: Does not require additional sensors, suitable for setups that already have current and voltage measurement devices.

Disadvantages: Relies on multiple assumptions, accuracy depends on initial measurements.

b. Thermal Network Model

Principle: Establish a thermal transfer model for the coil and its surrounding environment, considering heat conduction, convection, and radiation, to simulate temperature changes.

Usage:

Create a thermal network model of the coil and its cooling system.

Input operational parameters (e.g., current, ambient temperature), and use numerical simulation to calculate temperature distribution.

Advantages: Can predict temperature changes under complex conditions, suitable for design and optimization phases.

Disadvantages: Complex model requiring detailed data and computational resources.

c. Fiber Optic Temperature Sensors

Principle: Fiber optic temperature sensors use optical properties (such as Brillouin scattering, Raman scattering) that change with temperature to measure temperature.

Usage: Embed or wrap fiber optic sensors around the coil and use optical signal transmission and analysis to obtain temperature information.

Advantages: Resistant to electromagnetic interference, suitable for high-voltage and strong magnetic field environments.

Disadvantages: Higher cost and more complex technology.

3. Combined Methods

In practical applications, multiple methods are often combined to improve measurement accuracy and reliability. For example, thermocouples or RTDs can be installed at critical locations for direct measurement, while the copper loss method or thermal network models can be used for auxiliary calculations and validation.

Conclusion

Methods to determine coil temperature include both direct and indirect measurement approaches. Direct measurement methods, such as thermocouples, RTDs, and infrared thermometers, are suitable for scenarios requiring real-time monitoring. Indirect measurement methods, including the copper loss method, thermal network models, and fiber optic temperature sensors, are suited for specific applications or design optimization phases. Choosing the appropriate method based on specific needs and conditions ensures the safe operation and performance stability of the coil.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.