Types and Working of Cooling Tower

Purpose of a cooling tower is to reduce the temperature of circulating hot water to re-use this water again in the boiler. This hot water is coming from the condenser.

How Cooling Tower Works?

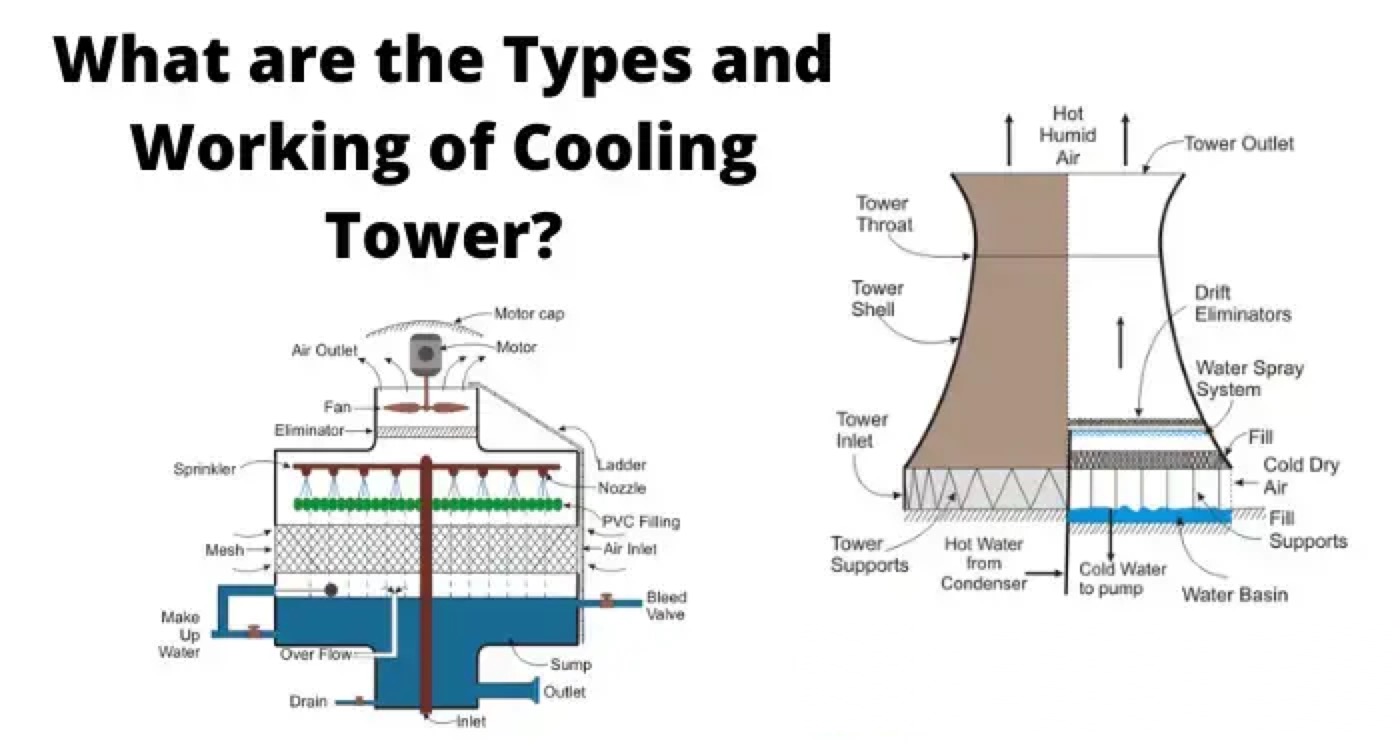

Hot water is coming at the inlet of the tower and pumped up to the header. The header contains nozzles and sprinklers which is used to spray water, and it will increase the surface area of water. After that, water comes to PVC filling; it used to reduce the speed of water. At the top the cooling tower, fans are used to lift air from bottom to the top.

Because of slow speed and more contact area of water, it makes a good connection between air and hot water. The process will reduce the temperature of water by evaporation process and cooled water is collected at the bottom of the cooling tower, and this cooled water is used again in the boiler.

Different Parts of Cooling Tower

Eliminator: It is not allowed to pass water. Eliminator is placed the at top of tower, from which only hot air can pass.

Spray Nozzles and Header: These parts are used to increase the rate of evaporation by increasing surface area of water.

PVC Falling: It reduces the falling speed of hot water and it is similar to beehive.

Mesh: When the fan is ON, it uses atmosphere air which contains some unwanted dust particles. Mesh is used to stop these particles and do not allow to enter dust in to cooling tower.

Float Valve: It is used to maintain level of water.

Bleed Valve: It is used to control the concertation of minerals and salt.

Body: Body or outer surface of cooling tower is often made up from FRP (fiber reinforced plastic), which protects the internal parts of cooling tower.

Types of Cooling Tower

Cooling towers can be classified in two types

1) Natural Draught Cooling Tower: In this type of cooling tower, fan is not used for circulating air but here, by enclosing the heated air in the chimney and it will create pressure difference between heated air and surrounding air. Because of this pressure difference air enters in to the cooling tower. It requires large hyperbolic tower, so capital cost is high but operating cost is low because of absence of electrical fan. There are two types of natural draught cooling tower, rectangular timber tower and reinforced concrete hyperbolic tower.

2) Mechanical or Forced Draught Cooling Tower: In this type of cooling tower, fan is used to circulate the air. When power plant runs on peak load, it requires a very high rate of cooling water. To rotate fan, it uses motor with speed around 1000 rpm. Working principle is same as natural draught cooling tower, only difference is that here fan is mounted on the cooling tower. If fan is mounted on the top of the tower is called as induced draught cooling tower which is most popular for very large capacity installation and requires large capacity of fan. So, forced draught cooling tower contains horizontal shaft for the fan and it is placed at bottom of the tower and induced draught cooling tower contains vertical shaft and it is placed at top of the cooling tower.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Electrical4U is dedicated to the teaching and sharing of all things related to electrical and electronics engineering.