What is a Surface Steam Condenser?

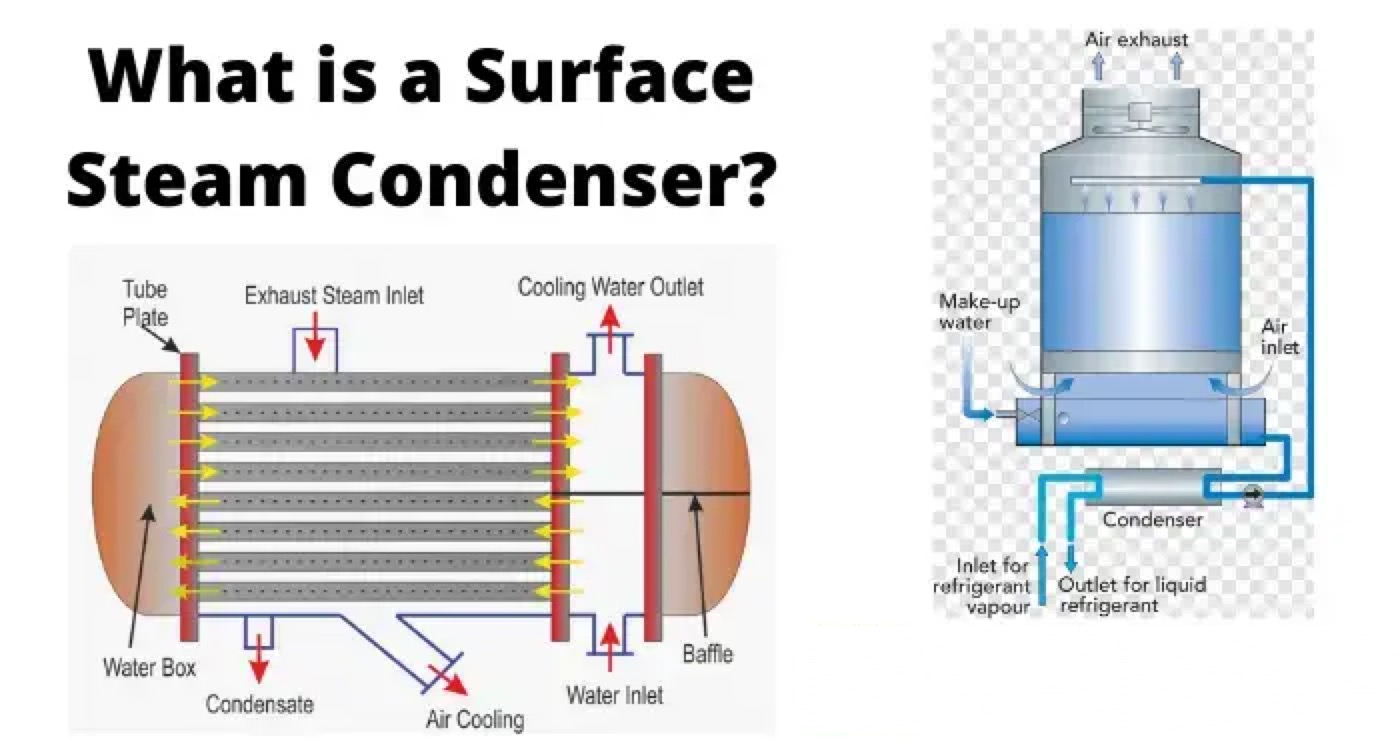

A surface steam condenser is a device that cools and condenses the exhaust steam from a steam turbine in a thermal power plant or other applications that use steam. The main purpose of a surface steam condenser is to increase the efficiency of the turbine by creating a low-pressure environment at the turbine outlet and to recover the pure water from the steam for reuse as boiler feed water.

A surface steam condenser consists of a shell that contains a large number of tubes through which cooling water flows. The exhaust steam passes over the tubes and transfers its heat to the cooling water, resulting in the condensation of the steam into liquid water. The condensed water, also known as condensate, is collected at the bottom of the shell and pumped out by a condensate extraction pump. The cooling water, which absorbs the heat from the steam, exits the shell and is circulated through a cooling tower or other heat rejection system.

A surface steam condenser also requires an air extraction pump that removes the air and other non-condensable gases from the shell. This creates a vacuum inside the shell, which lowers the pressure and temperature of the exhaust steam and enhances the heat transfer and condensation process.

There are different types and designs of surface steam condensers, depending on the flow direction of the steam and cooling water, the number of passes of the cooling water, and other factors. In this article, we will discuss some of the common types of surface steam condensers and their advantages and disadvantages.

Two-Flow Surface Condenser

A two-flow surface condenser is a type of surface condenser in which the cooling water flows through the tubes twice, once from one end to another, and then back from another end to the original end. The exhaust steam enters from the top of the shell and flows over the tubes, as shown in the figure below.

The advantages of a two-flow surface condenser are:

It has a simple design and construction.

It has a high heat transfer coefficient due to the counterflow arrangement of steam and cooling water.

It has a low-pressure drop across the tubes due to the short tube length.

The disadvantages of a two-flow surface condenser are:

It requires more cooling water than a single-flow surface condenser for the same amount of steam.

It has a higher risk of tube fouling due to the longer contact time between cooling water and the tube wall.

It has a lower vacuum efficiency due to the higher temperature difference between inlet and outlet cooling water.

Multi-Flow Surface Condenser

A multi-flow surface condenser is a type of surface condenser in which the cooling water flows through more than two passes in parallel through different sections of tubes. The exhaust steam enters from one side of the shell and flows over all sections of tubes, as shown in the figure below.

The advantages of a multi-flow surface condenser are:

It has a higher heat transfer rate than a two-flow surface condenser due to more contact area between steam and cooling water.

It has a lower pressure drop across the tubes due to the shorter tube length in each pass.

It has a higher vacuum efficiency due to the lower temperature difference between inlet and outlet cooling water.

The disadvantages of a multi-flow surface condenser are:

It has a more complex design and construction than a two-flow surface condenser.

It requires more cooling water than a two-flow surface condenser for the same amount of steam.

It has a higher risk of tube fouling due to more passes of cooling water.

Downflow Surface Condenser

A downflow surface condenser is a type of surface condenser in which the exhaust steam enters from the top of the shell and flows downward over the tubes. The cooling water enters from one end of the shell and flows through the tubes in one direction. The condensed water collects at the bottom of the shell and is pumped out by a condensate extraction pump. The air extraction pump is located at the lowest point of the shell, as shown in the figure below.

Central Flow Surface Condenser

A central flow surface condenser is a type of surface condenser in which the exhaust steam enters from the top of the shell and flows radially inward toward the center of the tube nest, where the air extraction pump is located. The cooling water enters from one end of the shell and flows through the tubes in one direction, as shown in the figure below.

The advantages of a central flow surface condenser are:

It has a better distribution of steam over the tube surface than a downflow surface condenser, as the steam has access to the whole periphery of the tubes.

It has a lower risk of air accumulation and corrosion than a downflow surface condenser, as the air is extracted from the center of the tube nest.

It has a lower pressure drop across the tubes than a downflow surface condenser, as the tube length is shorter.

The disadvantages of a central flow surface condenser are:

It has a more complex design and construction than a downflow surface condenser, as it requires a volute casting around the tube nest to direct the steam flow radially inward.

It has a lower heat transfer coefficient than a two-flow or multi-flow surface condenser, as the steam and cooling water flow in parallel rather than counterflow.

It has a higher risk of tube fouling than a two-flow or multi-flow surface condenser, as the cooling water flows only once through the tubes.

Inverted Flow Surface Condenser

An inverted flow surface condenser is a type of surface condenser in which the exhaust steam enters from near the bottom of the shell and flows upward over the tubes. The cooling water enters from one end of the shell and flows through the tubes in one direction. The condensed water collects at the bottom of the shell and is pumped out by a condensate extraction pump. The air extraction pump is located at the top of the shell, as shown in the figure below.

The advantages of an inverted flow surface condenser are:

It has a high heat transfer coefficient than a central flow or downflow surface condenser, as the steam and cooling water flow in counterflow rather than parallel.

It has a high vacuum efficiency than a central flow or downflow surface condenser, as the air is extracted from the top of the shell, where it is less dense and less humid.

It has a low risk of air accumulation and corrosion than a central flow or downflow surface condenser, as the air is extracted from the top of the shell, where it is less likely to mix with the condensate.

The disadvantages of an inverted flow surface condenser are:

It has a more complex design and construction than a central flow or downflow surface condenser, as it requires a special arrangement to introduce the steam near the bottom of the shell.

It has a higher pressure drop across the tubes than a central flow or downflow surface condenser, as the tube length is longer.

It has a higher risk of tube fouling than a two-flow or multi-flow surface condenser, as the cooling water flows only once through the tubes.

Evaporative Surface Condenser

An evaporative surface condenser is a type of surface condenser that is used when the supply of cooling water is very limited. In this condenser, the exhaust steam flows through a series of tubes, and a thin film of cooling water flows over the tubes. The cooling water evaporates partially due to the heat transfer from the steam, resulting in a higher rate of condensation. The condensed water and wet air are extracted from the tube outlet by an air extraction pump. A natural or forced air flow helps to accelerate the evaporation process. The cooling water that is not evaporated is collected in a tray and can be recycled as cooling water. An evaporative surface condenser requires only make-up water to compensate for the evaporation loss. This type of surface condenser is suitable for small power plants where water scarcity is an issue.

The advantages of an evaporative surface condenser are:

It has a low water consumption than other types of surface condensers, as it requires only make-up water to compensate for the evaporation loss.

It has a high cooling capacity than other types of surface condensers, as it utilizes both sensible and latent heat transfer mechanisms.

It has a low maintenance cost than other types of surface condensers, as it has fewer tubes and valves.

The disadvantages of an evaporative surface condenser are:

It has a high initial cost than other types of surface condensers, as it requires a special design and construction.

It has a high risk of scaling and corrosion than other types of surface condensers, as the cooling water is in direct contact with the tube surface and the air.

It has a high environmental impact than other types of surface condensers, as it emits water vapor and pollutants into the atmosphere.

Conclusion

Surface steam condensers are important devices that improve the efficiency and performance of steam turbines and other applications that use steam. They are designed to cool and condense the exhaust steam into pure water for reuse as boiler-feed water. They also create a vacuum inside the shell that lowers the pressure and temperature of the exhaust steam and enhances the heat transfer and condensation process.

There are different types and designs of surface steam condensers, depending on the flow direction of the steam and cooling water, the number of passes of the cooling water, and other factors. Some of the common types of surface steam condensers are two-flow, multi-flow, downflow, central flow, inverted flow, and evaporative. Each type has its own advantages and disadvantages that should be considered before selecting the best option for a specific application.

Surface steam condensers are widely used in thermal power plants, air conditioning systems, water cooling systems, and industrial facilities. They play a vital role in saving energy, water, and cost, as well as reducing emissions and pollution.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Electrical4U is dedicated to the teaching and sharing of all things related to electrical and electronics engineering.