Components of Electrostatic Precipitator

Electrostatic precipitators are mandatory nowadays in thermal power plants and other power plants where there is a discharge of flue gases. With ever increasing concern about environmental pollution and the need to reduce it, electrostatic precipitators have become a necessity. Electrostatic precipitator uses the high-intensity electric field to ionise the dust particles in the air stream, and then the dust particles get collected by oppositely charged collectors (electrodes). The dust particles, once collected are removed from the collector plates periodically by hammering the collectors.

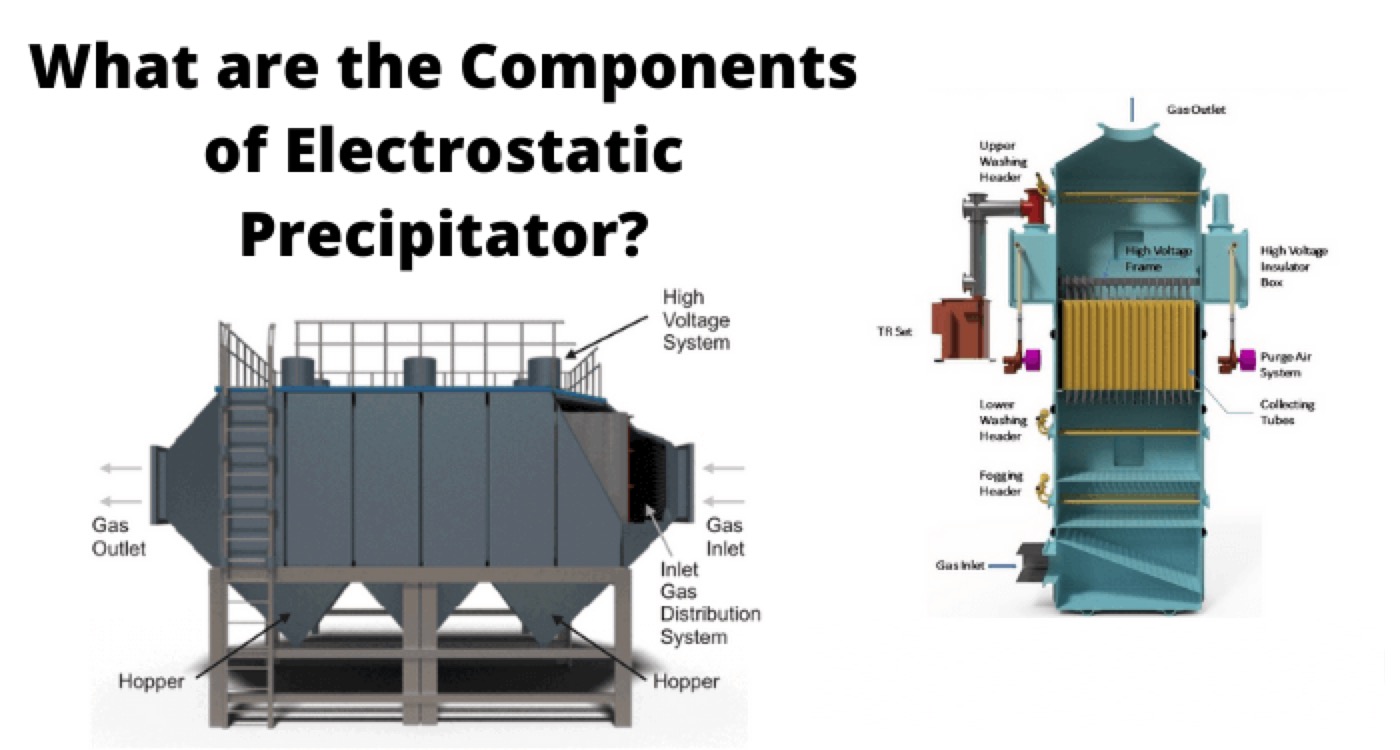

We are going to learn about the various components in an electrostatic precipitator in this articles so you can have a better understanding how electrostatic precipitator work and remove the impurities from the flue gases.

Here is a basic diagram of an electrostatic precipitator. Here you can see there is an AC supply which is fed to a control cabinet. The voltage is stepped up by using high voltage step-up transformer and then rectified by diodes. Once the AC is converted to dc, it is fed to the discharge electrodes. The flue gases pass through the discharge electrodes and get ionized. The collector electrodes, which has a polarity opposite to that of the ions, attract the ions. By hammering the collector electrodes, the dust particles are separated from the collector electrodes and is collected by the hopper.

So, in short, the various components in an electrostatic precipitator are:

Electrodes

440v 50hz 3 phase supply

High voltage transformer

Rectifier

Hooper

Insulators

Here is a more detailed diagram of an electrostatic precipitator

Now we will go through some of these components in detail:

Electrodes

Discharge electrodes are made up of tubes containing welded and annealed copper wires of small diameter. The wires hang vertically and can produce a high amount of corona discharge. Their main function is to generate a high-intensity electric field and ionize the particles in the flue gas.

Collecting electrodes are made of sheet metal. They attract the particulate matter.

Rapper Coils

Rapper coils deliver a shearing force of high strength to dislodge the particles from the collecting electrodes. They hit the collecting electrodes at set time intervals for collecting the dust particles in the hopper.

Transformer Rectifier Unit

High voltage DC is required to charge the discharge electrodes to produce the corona effect. To do that, first, the voltage is first stepped up using a high voltage transformer. Then the AC supply is changed into DC. The DC supply is then fed to the discharge electrodes.

Hopper

Hopper is a large pyramidal shaped container that collects the particulate matter. They are made up of steel. The dust collected in the collecting electrodes gets transferred into the hopper when rapper coils dislodge the particles from the electrodes. The hopper collects the dust particles. Once the hopper reaches maximum capacity, the dust is expelled out through an opening in the bottom. Vibrators are installed on the outer walls to release the particulate matter.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Electrical4U is dedicated to the teaching and sharing of all things related to electrical and electronics engineering.