Advantages and Disadvantages of Electrostatic Precipitator

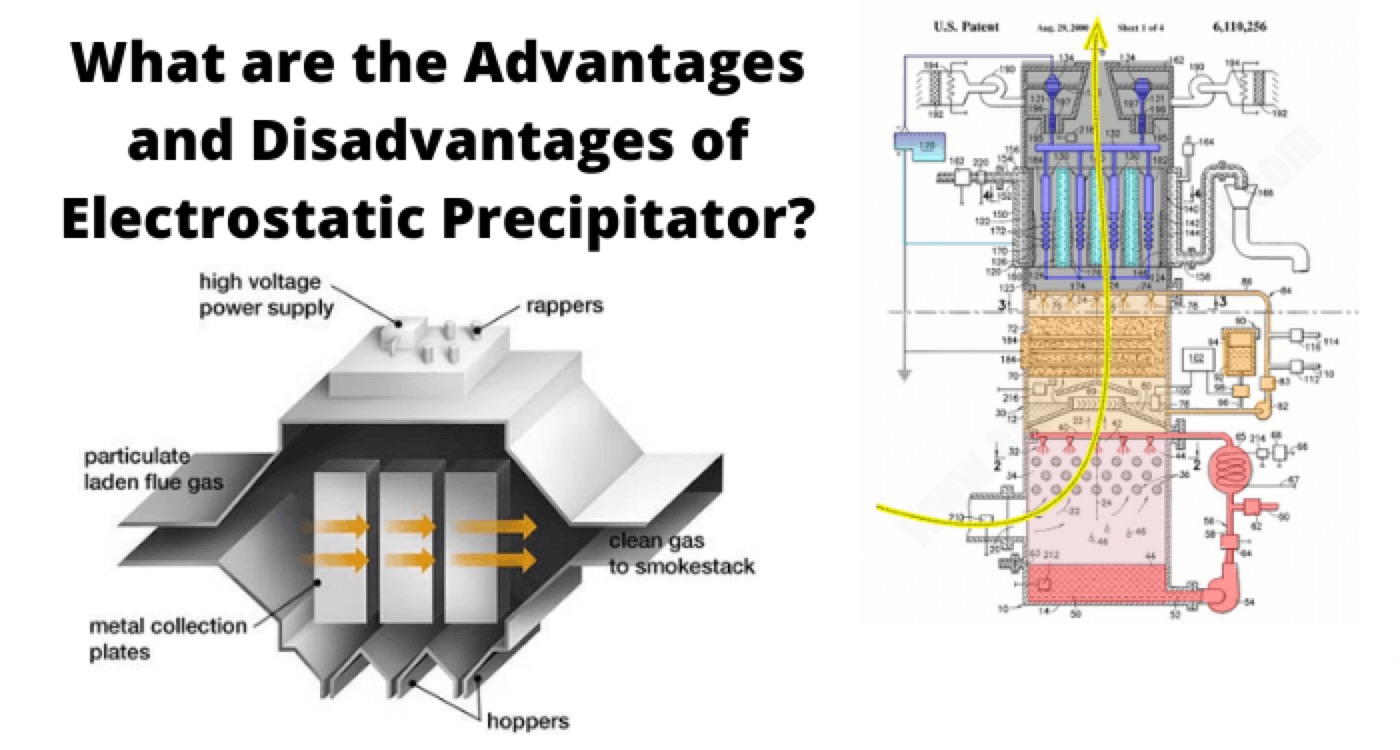

Electrostatic precipitators are ubiquitous nowadays in thermal power plants due to ever-increasing concern about environmental pollution. Electrostatic precipitator uses the high-intensity electric field to ionise the dust particles in the air stream and then the dust particles are collected by oppositely charged collectors (electrodes). The dust particles, once collected are removed from the collector plates periodically by hammering the collectors by a different mechanism.

But all devices have their pros and cons and we are going to discuss that in this article. After familiarising ourselves with the advantages and disadvantages of electrostatic precipitators, we are going to decide whether having them in a thermal power plant adds overall value.

Note: ESP will mean electrostatic precipitator whenever it is used in the articles.

Advantages of Electrostatic Precipitator

• The High Efficiency of Removal of Particles/Pollutants

The efficiency of an electrostatic precipitator depends on a lot of factors like the resistivity of the particles, the corona power ratio etc. For removal of particles under normal circumstances, their efficiency is very high, up to 99% removal of dust particles. Electrostatic precipitators have relatively high collection efficiencies (99-100%) over a wide range of particle sizes (∼0.05-5 μm).

• Collection of Dry as Well as Wet Pollutants

There are two types of electrostatic precipitators: wet and dry. Dry ESPs are used for collection of dry pollutants like ash or cement particles. Wet ESPs are used to remove wet particles like as resin, oil, paint, tar, acid or anything that is not dry in the conventional sense.

• Low Operating Costs

Operating costs for electrostatic precipitators are low and in the long run, they are economically feasible.

Disadvantages of Electrostatic Precipitator

• High Capital Costs

Electrostatic precipitators have a high initial capital cost, which makes it prohibitive for small-scale industries. They are expensive to purchase and install.

• Requires Large Space

In addition to being costly, they require large space to be set up. Again the value proposition for small-scale industries gets reduced as they are costly as well as need a lot of space to be set up.

• Not Flexible Once Installed

Electrostatic precipitators do not offer the flexibility of operation. Once installed, it is difficult to change the capacity of the ESP or move it to a different location. So proper planning needs to be done regarding the capacity, type and location for installing the ESP.

• They cannot be used to collect gaseous pollutants

An electrostatic precipitator can be used for collecting only dry and wet pollutants and not for gaseous pollutants. This is a major disadvantage of ESPs.

So, after going through the advantages and disadvantages of electrostatic precipitators, we are in a position to conclude whether we should install ESPs in a thermal power plant. Initial cost is definitely high and that makes it difficult for small-scale industries to install it. But with government support, the cost can be reduced for these sectors. With proper planning and land allocation, the disadvantage of being inflexible and large space requirement can be negated. ESPs can be used every effectively for dry and wet pollutants. Hence installing them can bring a lot of benefits to the plant in the long run and keep the environment safe.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Electrical4U is dedicated to the teaching and sharing of all things related to electrical and electronics engineering.