Electric Arc Furnace

Electric Arc Furnace means an extremely hot enclosed space, where heat is produced by means of electrical arcing for melting certain metals such as scrap steel without changing electro-chemical properties of the metal.

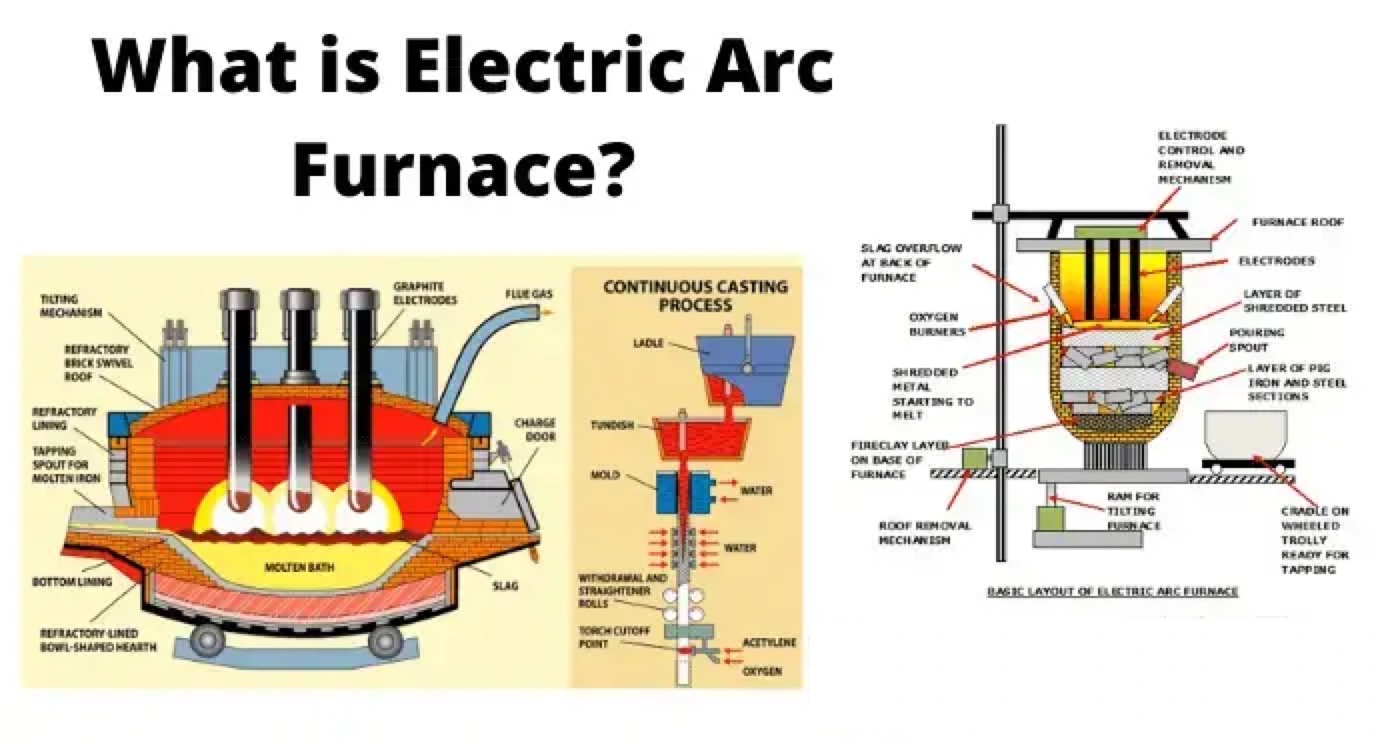

Here, electric arc is produced between the electrodes. This electric arc is used for melting the metal. The arc furnaces are used to produce mini steel structural bars and steel rods. The electric furnace is in form of a vertical vessel of fire brick. There are mainly two types of electric furnaces. They are alternating current (AC) and direct current (DC) operated electric furnaces.

DC Electric Arc Furnace

DC Arc Furnace is recent and advanced furnace compared to AC Arc Furnace. In DC Arc Furnace, current flows from cathode to anode. This furnace has only a single graphite electrode and the other electrode is embedded at the bottom of the furnace. There are different methods for fixing anode at the bottom of the DC furnace.

The first arrangement consists of a single metal anode placed at the bottom. It is water cooled because it gets heated up fast. In the next one, the anode be the conducting hearth by C-MgO lining. The current is given to the Cu plate positioned at the bottom portion. Here, the cooling of anode is by the air. In the third arrangement, the metal rods act as anode. It is entrenched in MgO mass. In the fourth arrangement, the anode is the thin sheets. The sheets are entrenched in MgO mass.

Advantages of DC Electric Arc Furnace

Decrease in electrode consumption by 50%.

Melting is almost uniform.

Decrease in power consumption (5 to 10%).

Decrease in flicker by 50%.

Decrease in refractory consumption

Hearth life can be extended.

AC electric Arc Furnace

In AC electric furnace, current flows between the electrodes through the charges in metal. In this furnace three graphite electrodes are used as cathode. The scrap itself acts as an anode. When compared to DC arc furnace, this is cost effective. This furnace is most commonly used in small furnaces.

Construction of Electric Arc Furnace

As mentioned above, the electric furnace is a large firebrick lined erect vessel. It is demonstrated in figure 2.

The main parts of electric furnace are the roof, hearth (lower part of a furnace, from where molten metal is collected), electrodes, and side walls. The roof consists of three holes through which the electrodes are inserted. The roof is made up of alumina and magnesite-chromite bricks. The hearth includes metal and slag. The tilting mechanism is used to pour the metal that is molten to the cradle by shifting the furnace. For the electrode removal and furnace charging (topping up scrap metals), roof retraction mechanism is incorporated. The provision for fume extraction is also given around the furnace considering the health of operators. In AC electric furnace, electrodes are three in number. These are round in section. Graphite is used as electrodes because of high electric conductivity. Carbon electrodes are also used. The electrodes positioning system helps to raise and lower the electrodes automatically. The electrodes get highly oxidized when the current density is high.

Transformer: –

The transformer provides the electrical supply to the electrodes. It is located near to the furnace. It is well protected. The rating of large electric arc furnace may be up to 60MVA.

Working Principle of Electrical Arc Furnace

The working of electric furnace includes charging the electrode, meltdown period (melting the metal) and refining. The heavy and light scrap in the large basket is preheated with the help of exhaust gas. For speeding up the slag formation, burnt lime and spar are added to it. The charging of furnace takes place by swinging the roof of the furnace. As per requirement, the hot metal charging also takes place.

Next is the meltdown period. The electrodes are moved down onto the scrap in this period. Then the arc is produced between the electrode and metal. By considering the protection aspect, low voltage is selected for this. After the arc is shielded by electrodes, the voltage is increased for speeding up the melting process. In this process, carbon, silicon, and manganese get oxidized. The lower current is required for large arc production. The heat loss is also less in this. Melting down process can be fastening by deep bathing of electrodes.

Refining process starts during melting. The removal of sulfur is not essential for single oxidizing slag practice. Only phosphorous removal is required in this. But in double slag practice, both (S and P) are to be removed. After the deoxidizing; in double slag practice, the removal of oxidizing slag is performed. Next, with the help of aluminum or ferromanganese or ferrosilicon, it gets deoxidized. When the bathing chemistry and required temperature is reached, the heat will get deoxidized. Then, the molten metal is ready for tapping.

For the cooling of the furnace, tubular pressure panels or hollow annulus spraying can be used.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Electrical4U is dedicated to the teaching and sharing of all things related to electrical and electronics engineering.