Diesel Power Plant: A Comprehensive Guide

A diesel power plant is a type of power plant that uses a diesel engine as the prime mover to drive an alternator and generate electricity. Diesel power plants are mainly used for small-scale power generation or as backup sources of electricity in remote areas or during emergencies. In this article, we will discuss the components, working principles, advantages, disadvantages, and applications of diesel power plants.

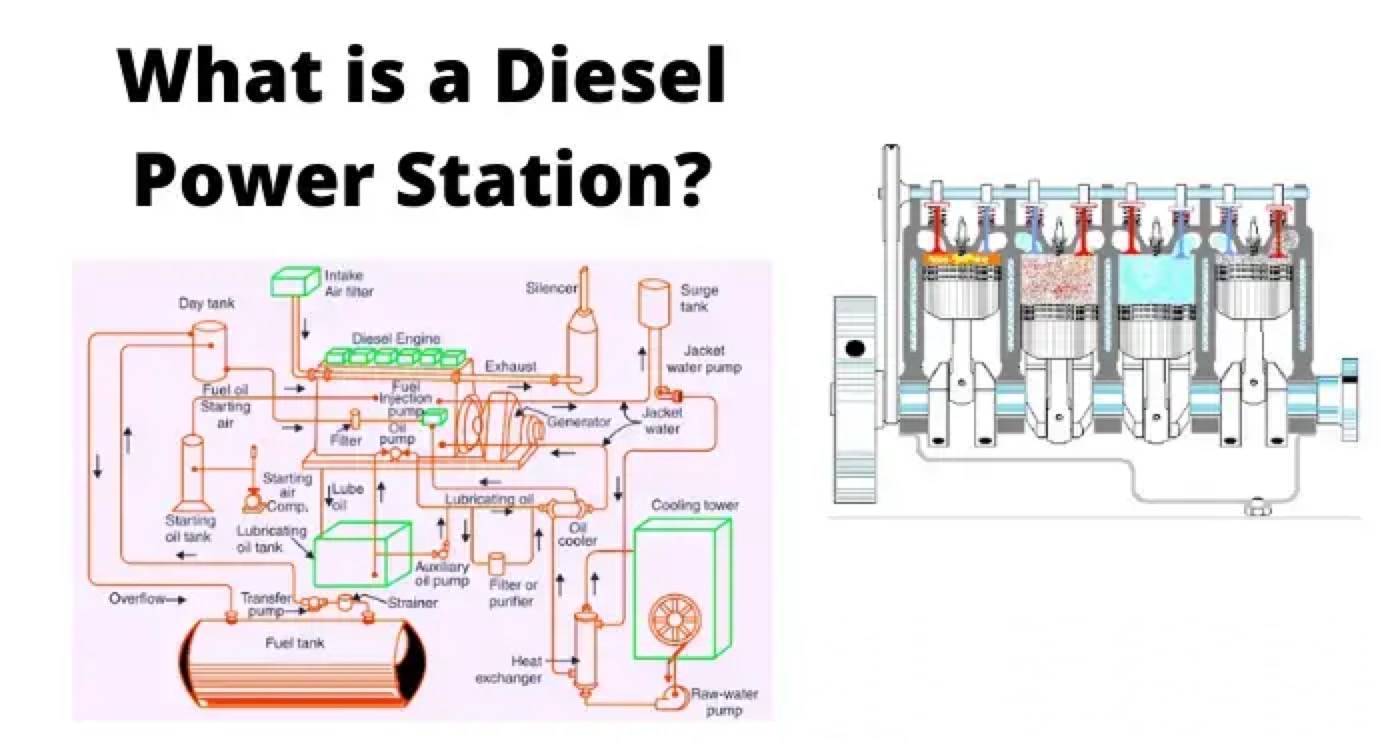

What is a Diesel Power Plant?

A diesel power plant is defined as a power plant that uses a diesel engine as the prime mover to drive an alternator and generate electricity. A diesel engine is an internal combustion engine that converts the chemical energy of diesel fuel into mechanical energy. The mechanical energy is then used to rotate the shaft of an alternator, which converts it into electrical energy.

A diesel power plant consists of several systems and components that work together to produce electricity. The main components of a diesel power plant are:

Diesel engine

Air intake system

Exhaust system

Fuel supply system

Cooling system

Lubrication system

Starting system

Alternator

Control panel

The schematic diagram of a diesel power plant is shown below:

!https://www.electricaltechnology.org/wp-content/uploads/2021/08/Schematic-Diagram-of-Diesel-Power-Plant.png

The working principle of a diesel power plant is based on the four-stroke cycle of a diesel engine. The four strokes are:

Intake stroke: The air intake system draws fresh air from the atmosphere and filters it to remove dust and dirt. The filtered air is then compressed by the piston in the cylinder.

Compression stroke: The piston moves up and compresses the air in the cylinder to high pressure and temperature.

Power stroke: The fuel supply system injects a measured amount of diesel fuel into the cylinder through a fuel injector. The fuel mixes with the compressed air and ignites spontaneously due to the high temperature. The combustion of fuel releases a large amount of energy, which pushes the piston down and creates a power stroke.

Exhaust stroke: The piston moves up again and expels the exhaust gases from the cylinder through the exhaust valve. The exhaust system removes the exhaust gases from the engine and reduces the noise level.

The above cycle is repeated for each cylinder of the engine. The power strokes of different cylinders are synchronized to produce a smooth and continuous rotation of the crankshaft. The crankshaft is connected to the alternator by a coupling or a belt. The alternator converts the mechanical energy of the crankshaft into electrical energy. The electrical energy is then delivered to the load or the grid through a control panel.

The cooling system circulates water or air through the engine to remove excess heat and maintain an optimal temperature. The lubrication system supplies oil to the moving parts of the engine to reduce friction and wear. The starting system provides compressed air or electricity to start the engine initially.

Advantages of Diesel Power Plant

Some of the advantages of diesel power plants are:

They are simple in design and easy to install.

They require less space and can be designed for portable use.

They have quick starting and stopping capabilities, which reduce standby losses.

They have high thermal efficiency and low fuel consumption compared to coal-fired plants.

They can operate independently of external sources of water or coal.

They can provide a reliable and flexible power supply for peak load or emergency situations.

Disadvantages of Diesel Power Plant

Some of the disadvantages of diesel power plants are:

They have high operating and maintenance costs due to the high price of diesel fuel and lubricants.

They have limited capacity and are not suitable for large-scale power generation.

They produce noise and air pollution due to exhaust emissions.

They cannot operate under overload conditions for long periods.

Applications of Diesel Power Plants

Some of the applications of diesel power plants are:

They are used as standby or backup sources of electricity for industries, commercial complexes, hospitals, etc., during power outages or grid failures.

They are used as mobile or portable sources of electricity for remote areas, construction sites, military camps, etc., where the grid connection is not available or feasible.

They are used as peak load plants to supplement other types of power plants during periods of high demand or low supply.

They are used as emergency plants for essential services such as communication, water supply, etc., during natural disasters or wars.

They are used as starting plants for large steam or hydroelectric plants that require the initial rotation of their turbines.

Conclusion

Diesel power plants are one of the types of power plants that use diesel engines as prime movers to generate electricity. They have several advantages, such as simplicity, reliability, flexibility, and efficiency, but they also have some disadvantages, such as high cost, limited capacity, noise, and pollution. They are mainly used for small-scale power generation or as backup sources of electricity in remote areas or during emergencies.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

We aim to gather electrical knowledge and share it with others.