Thermal Power Generation Plant or Thermal Power Station

What is a Thermal Power Plant?

A thermal power generation plant or thermal power station is the most conventional source of electric power. The thermal power plant is also referred to as a coal thermal power plant and steam turbine power plant.

Let’s dive into how a thermal power plan works.

Theory of Thermal Power Station

The theory of thermal power stations or the working of the thermal power stations is very simple. A power generation plant mainly consists of alternator runs with help of a steam turbine. The steam is obtained from high-pressure boilers.

Generally in India, bituminous coal, brown coal, and peat are used as fuel for the boiler. The bituminous coal is used as boiler fuel has volatile matter from 8 to 33% and ash content 5 to 16%. To increase thermal efficiency, coal is used in the boiler in powder form.

In a coal thermal power plant, the steam is produced at high pressure in the steam boiler due to the burning of fuel (pulverized coal) in boiler furnaces. This steam is further supper heated in a superheater.

This superheated steam then enters into the turbine and rotates the turbine blades. The turbine is mechanically so coupled with an alternator that its rotor will rotate with the rotation of turbine blades.

After entering in turbine the steam pressure suddenly falls and the corresponding volume of the steam increases.

After imparting energy to the turbine rotor, the steam passes out of the turbine blades into the condenser.

In the condenser, the cold water is circulated with the help of a pump which condenses the low-pressure wet steam.

This condensed water is further supplied to a low-pressure water heater where the low-pressure steam increases the temperature of this feed water; it is again heated at high pressure.

For better understanding, we furnish every step of the function of a thermal power station as follows,

First, the pulverized coal is burnt into the furnace of steam boiler.

High-pressure steam is produced in the boiler.

This steam is then passed through the superheater, where it further heated up.

This super heated steam is then entered into a turbine at high speed.

In turbine, this steam force rotates the turbine blades that means here in the turbine the stored potential energy of the high pressured steam is converted into mechanical energy.

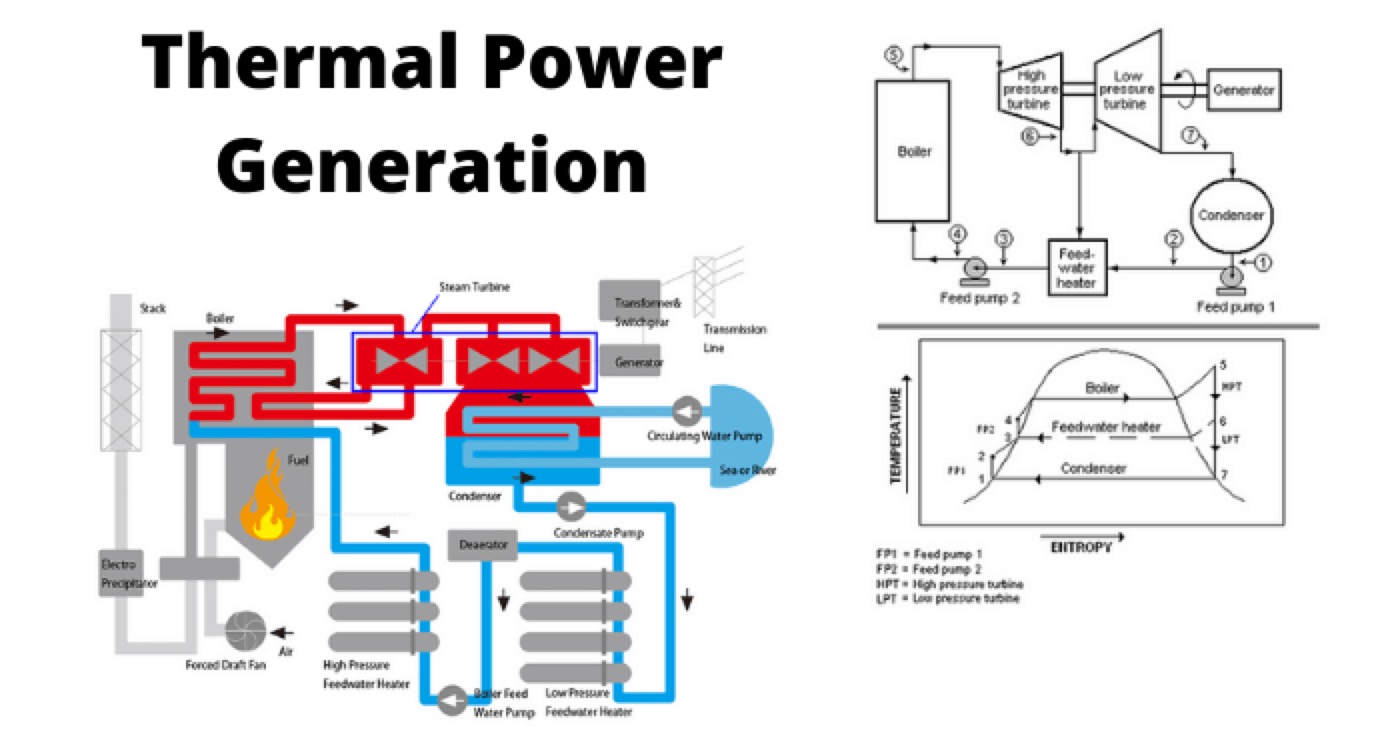

Line Diagram of Power Plant

After rotating the turbine blades, the steam has lost its high pressure, passes out of turbine blades, and enters into a condenser.

In the condenser, the cold water is circulated with help of a pump which condenses the low-pressure wet steam.

This condensed water is then further supplied to a low-pressure water heater where the low-pressure steam increases the temperature of this feed water, it is then again heated in a high-pressure heater where the high pressure of steam is used for heating.

The turbine in the thermal power station acts as a prime mover of the alternator.

Overview of Thermal Power Plant

A typical Thermal Power Station Operates on a Cycle which is shown below.

The working fluid is water and steam. This is called the feed water and steam cycle. The ideal Thermodynamic Cycle to which the operation of a Thermal Power Station closely resembles is the rankine cycle.

In a steam boiler, the water is heated up by burning the fuel in the air in the furnace, and the function of the boiler is to give dry superheated steam at the required temperature. The steam so produced is used in driving the steam Turbines.

This turbine is coupled to the synchronous generator (usually a three-phase synchronous alternator), which generates electrical energy.

The exhaust steam from the turbine is allowed to condense into the water in the steam condenser of turbine, which creates suction at very low pressure and allows the expansion of the steam in the turbine to very low pressure.

The principal advantages of the condensing operation are the increased amount of energy extracted per kg of steam and thereby increasing efficiency, and the condensate which is fed into the boiler again reduces the amount of fresh feed water.

The condensate along with some fresh makeup feed water is again fed into the boiler by a pump (called the boiler feed pump).

In the condenser, the steam is condensed by cooling water. Cooling water recycles through the cooling tower. This constitutes a cooling water circuit.

The ambient air is allowed to enter the boiler after dust filtration. Also, the flue gas comes out of the boiler and gets exhausted into the atmosphere through stacks. These constitute air and flue gas circuits.

The flow of air and also the static pressure inside the steam boiler (called draught) is maintained by two fans called Forced Draught (FD) fan and Induced Draught (ID) fan.

The total scheme of a typical thermal power station along with different circuits is illustrated below.

Inside the boiler, there are various heat exchangers, viz. Economizer, Evaporator (not shown in the fig above, it is basically the water tubes, i.e. downcomer riser circuit), Super Heater (sometimes Reheater, air preheater are also present).

In Economiser the feed water is heated to a considerable amount by the remaining heat of flue gas.

The Boiler Drum maintains a head for natural circulation of a two-phase mixture (steam + water) through the water tubes.

There is also a Super Heater which also takes heat from flue gas and raises the temperature of steam as per requirement.

The efficiency of Thermal Power Station or Plant

The overall efficiency of the steam power plant is defined as the ratio of heat equivalent of electrical output to the heat of combustion of coal. The overall efficiency of a thermal power station or plant varies from 20% to 26% and it depends upon plant capacity.

Installed plant capacity |

Average overall thermal efficiency |

upto 1MW |

4% |

1MW to 10MW |

12% |

10MW to 50MW |

16% |

50MW to 100MW |

24% |

above 100MW |

27% |

Thermal Power Plant Location

A thermal power station or thermal power plant has an ultimate target to make a business profitable. Hence for optimizing the profit, the location of the station is much important factor.

Power generation plant location plays an optimizing part in the economy of the station.

The most economical location of a power plant can be determined by the graphical method as described below,

The most economical and ideal power plant location is the center of gravity of the load because for such a power generation plant the length of the power transmission network will be minimum, thus the capital cost to the system is reduced.

Let’s explain the graphical method, say, X and Y be two reference axes.

Let’s Q1(x1, y1), Q2(x2, y2), Q3(x3, y3), Q4(x4, y4),……………………………………….and Qn(xn, yn) are n numbers of load centers.

From the above graph we get, the coordinates of the center of gravity of the load, Q(x, y) where

The location of the thermal power station is best at the center of gravity of the load, but many times it is not possible to establish a thermal power plant at the CG of the load.

Since normally CG point of the load may be at the heart of the city. So other points are to be considered to decide the best-optimized location of the power plant.

The electric power generation plant must be constructed at such a place where the cost of land is quite reasonable.

The land should be such that the acquisition of private property must be minimum.

A large quantity of cooling water is required for the condensers etc of thermal power generation plant, hence the plant should preferably be situated beside the big source of a natural water source such as a big river.

Availability of a huge amount of fuel at a reasonable cost is one of the major criteria for choosing a plant location.

The plant should be established on plane land.

The soil should be such that it should provide a good and firm foundation of plants and buildings.

The thermal power plant location should not be very nearer to the dense locality as there is smoke, noise steam, water vapors, etc.

There must be ample scope of development of future demand.

A place for an ash handling plant for thermal power stations should also be available very nearby.

A very tall chimney of power station should not obstruct the traffics of airships.

Advantages of Thermal Power Station

The advantages of a thermal power station include:

Economical for low initial cost other than any generating plant.

Land required less than hydropower plant.

Since coal is the main fuel and its cost is quite cheap than petrol/diesel so generation cost is economical.

Maintenance is easier.

Thermal power plants can be installed in any location where transportation and bulk of water are available.

Disadvantages of Thermal Power Station

The disadvantages of a thermal power station include:

The running cost for a thermal power station is comparatively high due to fuel, maintenance, etc.

A large amount of smoke causes air pollution. The thermal power station is responsible for Global warming.

The heated water that comes from the thermal power plants has an adverse effect on the aquatic lives in the water and disturbs the ecology.

The overall efficiency of the thermal power plant is low like less than 30%.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

We aim to gather electrical knowledge and share it with others.