Thermoelectric Generators: Principles, Materials and Applications

A thermoelectric generator (TEG) is a device that converts heat energy into electrical energy using the Seebeck effect. The Seebeck effect is a phenomenon that occurs when a temperature difference exists between two different conductors or a circuit of conductors, creating an electric potential difference. TEGs are solid-state devices that have no moving parts and can operate silently and reliably for long periods of time. TEGs can be used to harvest waste heat from various sources, such as industrial processes, automobiles, power plants, and even human body heat, and convert it into useful electricity. TEGs can also be used to power remote devices, such as sensors, wireless transmitters, and spacecraft, by using radioisotopes or solar heat as the heat source.

How Does a Thermoelectric Generator Work?

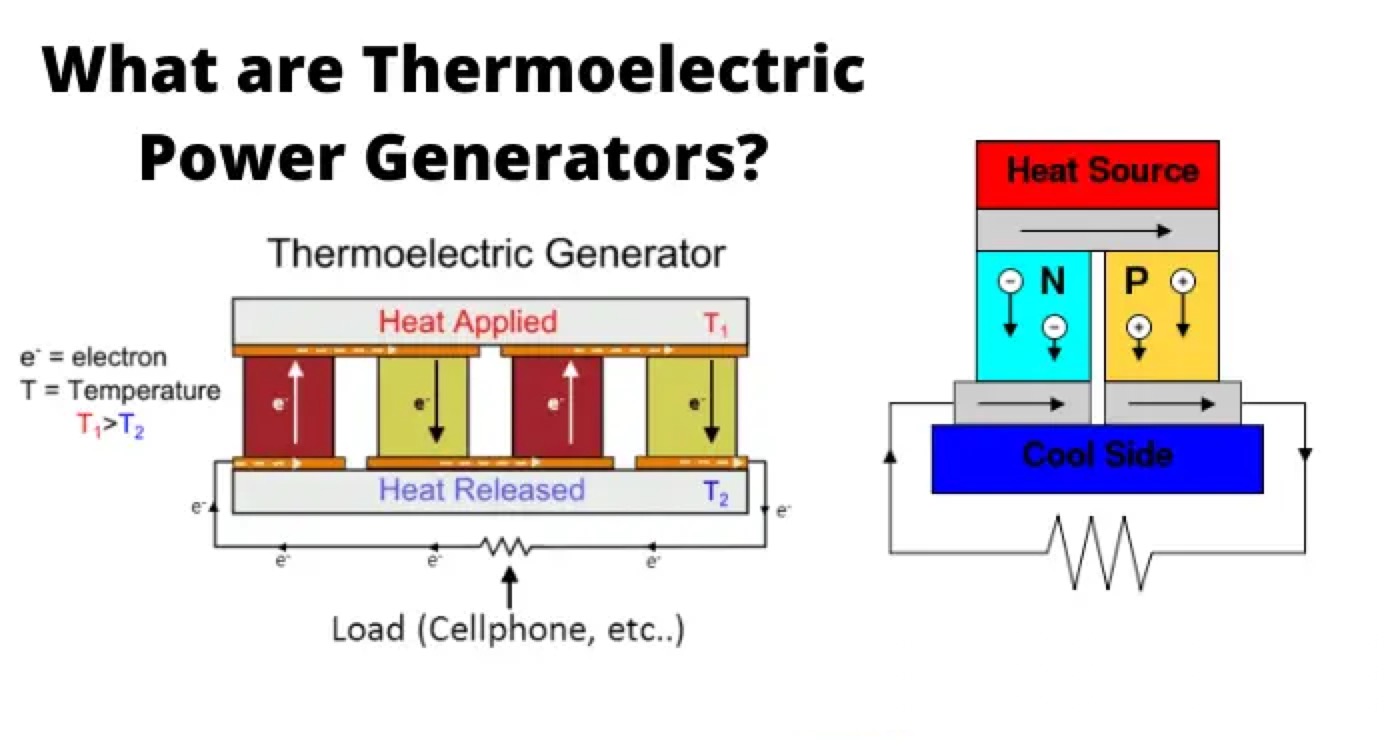

A thermoelectric generator consists of two main components: thermoelectric materials and thermoelectric modules.

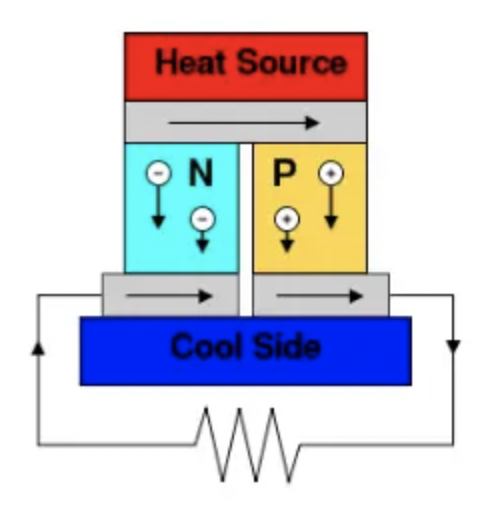

Thermoelectric materials are materials that exhibit the Seebeck effect, meaning that they generate an electric voltage when subjected to a temperature gradient. Thermoelectric materials can be classified into two types: n-type and p-type. N-type materials have an excess of electrons, while p-type materials have a deficiency of electrons. When an n-type material and a p-type material are connected in series by metal electrodes, they form a thermocouple, which is the basic unit of a thermoelectric generator.

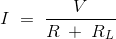

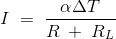

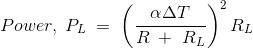

A thermoelectric module is a device that contains many thermocouples connected electrically in series and thermally in parallel. A thermoelectric module has two sides: a hot side and a cold side. When the hot side is exposed to a heat source and the cold side is exposed to a heat sink, a temperature difference is created across the module, causing a current to flow through the circuit. The current can be used to power an external load or charge a battery. The voltage and power output of a thermoelectric module depends on the number of thermocouples, the temperature difference, the Seebeck coefficient, and the electrical and thermal resistances of the materials.

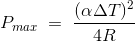

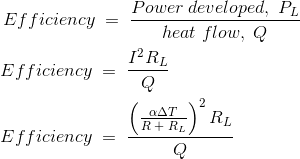

The efficiency of a thermoelectric generator is defined as the ratio of the electrical power output to the heat input from the source. The efficiency of a thermoelectric generator is limited by the Carnot efficiency, which is the maximum possible efficiency for any heat engine operating between two temperatures. The Carnot efficiency is given by:

ηCarnot=1−ThTc

where Tc is the temperature of the cold side, and Th is the temperature of the hot side.

The actual efficiency of a thermoelectric generator is much lower than the Carnot efficiency due to various losses such as Joule heating, thermal conduction, and thermal radiation. The actual efficiency of a thermoelectric generator depends on the figure of merit (ZT) of the thermoelectric materials, which is a dimensionless parameter that measures the performance of a material for thermoelectric applications. The figure of merit is given by:

ZT=κα2σT

where α is the Seebeck coefficient, σ is the electrical conductivity, κ is the thermal conductivity, and T is the absolute temperature.

The higher the figure of merit, the higher the efficiency of the thermoelectric generator. The figure of merit depends on both intrinsic properties (such as electron and phonon transport) and extrinsic properties (such as doping level and geometry) of the materials. The goal of thermoelectric materials research is to find or design materials that have a high Seebeck coefficient, high electrical conductivity, and low thermal conductivity, which are often conflicting requirements.

What are Some Common Thermoelectric Materials?

Thermoelectric materials can be classified into three categories: metals, semiconductors, and complex compounds.

Metals have high electrical conductivity but low Seebeck coefficient and high thermal conductivity, resulting in a low figure of merit. Metals are mainly used as electrodes or interconnects in thermoelectric modules.

Semiconductors have moderate electrical conductivity and Seebeck coefficient but high thermal conductivity, resulting in a moderate figure of merit. Semiconductors can be doped to create n-type or p-type materials with different carrier concentrations and mobilities. Semiconductors are widely used as thermoelectric materials for low-temperature applications (below 200°C).

Complex compounds have low electrical conductivity but a high Seebeck coefficient and low thermal conductivity, resulting in a high figure of merit. Complex compounds are usually composed of multiple elements with different valence states and crystal structures, which create complex electronic band structures and phonon scattering mechanisms that enhance thermoelectric performance. Complex compounds are widely used as thermoelectric materials for high-temperature applications (above 200°C).

Some examples of common thermoelectric materials are:

Bismuth telluride (Bi2Te3) and its alloys: These are the most widely used thermoelectric materials for low-temperature applications (below 200°C), such as cooling devices and power generation from waste heat sources. Bi2Te3 has a layered structure that consists of alternating quintuple layers of Bi2 and Te3 atoms bonded by weak van der Waals forces. This structure results in low thermal conductivity due to phonon scattering at the layer boundaries. Bi2Te3 can be alloyed with other elements such as antimony (Sb), selenium (Se), or sulfur (S) to tune its electrical properties and optimize its figure of merit.

Lead telluride (PbTe) and its alloys: These are among the most widely used thermoelectric materials for medium-temperature applications (200-600°C), such as power generation from automotive exhaust or industrial waste heat sources. PbTe has a rock-salt structure that consists of alternating layers of Pb2+ and Te2- ions bonded by strong ionic forces. This structure results in a high Seebeck coefficient due to heavy Pb atoms that create large band degeneracy near the Fermi level. PbTe can be alloyed with other elements such as tin (Sn), thallium (Tl), or sodium (Na) to enhance its figure of merit.

Skutterudites: These are complex compounds with the general formula MX3, where M is a transition metal (such as cobalt, Co) and X is a pnictogen (such as antimony, Sb).

Skutterudites have a cubic structure that consists of a three-dimensional network of M4X12 units with large voids that can accommodate guest atoms (such as rare earth elements, RE). The guest atoms act as phonon scatterers that reduce the thermal conductivity, while the host atoms provide high electrical conductivity and Seebeck coefficient. Skutterudites are promising thermoelectric materials for medium- to high-temperature applications (300-800°C), such as power generation from waste heat recovery or concentrated solar power.

Half-Heusler compounds: These are ternary compounds with the general formula XYZ, where X is a transition metal (such as titanium, Ti), Y is another transition metal (such as nickel, Ni), and Z is a main group element (such as tin, Sn).

Half-Heusler compounds have a cubic structure that consists of four interpenetrating fcc sublattices, one occupied by X atoms and the other three occupied by Y and Z atoms in a 1:2 ratio. Half-Heusler compounds have high Seebeck coefficient and electrical conductivity due to their complex electronic band structures and low thermal conductivity due to their heavy constituent atoms. Half-Heusler compounds are promising thermoelectric materials for high-temperature applications (above 800°C), such as power generation from nuclear reactors or aerospace engines.

What are Some Applications of Thermoelectric Generators?

Thermoelectric generators have various applications in different fields, depending on the temperature range, power output, and heat source availability. Some examples of thermoelectric generator applications are:

Cooling devices: Thermoelectric generators can be used to cool electronic components, such as microprocessors, lasers, or sensors, by applying an electric current to create a temperature difference between the hot and cold sides of the module. This process is called thermoelectric cooling or the Peltier effect, which is the reverse of the Seebeck effect. Thermoelectric cooling devices have advantages over conventional cooling methods, such as compactness, reliability, noiselessness, and precise temperature control.

Power generation from waste heat: Thermoelectric generators can be used to harvest waste heat from various sources, such as industrial processes, automobiles, power plants, and even human body heat, and convert it into useful electricity. This can improve energy efficiency and reduce the greenhouse gas emissions of these sources. For example, thermoelectric generators can be integrated into automotive exhaust systems to recover some of the heat lost during combustion and generate electricity for onboard electronics or battery charging. Thermoelectric generators can also be attached to human skin or clothing to generate electricity from body heat for powering wearable devices or medical implants.

Power generation from radioisotopes: Thermoelectric generators can be used to power remote devices, such as sensors, wireless transmitters, and spacecraft, by using radioisotopes as the heat source.

Radioisotopes are unstable isotopes that emit radiation and decay into other elements. The radiation can be converted into heat by using a material that absorbs it, such as lead or tungsten. The heat can then be converted into electricity by using thermoelectric modules. Radioisotope thermoelectric generators (RTGs) have advantages over other power sources, such as batteries or solar panels, in terms of long lifetime, high reliability, and independence from environmental conditions. RTGs have been used to power many space missions, such as Voyager 1 and 2, Curiosity rover, and Perseverance rover.

What are Some Challenges and Future Directions for Thermoelectric Generators?

Thermoelectric generators have many potential benefits for energy conversion and harvesting applications, but they also face some challenges and limitations that need to be overcome for practical implementation. Some of these challenges are:

Low efficiency: The efficiency of thermoelectric generators is limited by the Carnot efficiency and the figure of merit of the thermoelectric materials. The current state-of-the-art thermoelectric materials have a figure of merit around 1-2 at room temperature and 2-3 at high temperature, resulting in an efficiency of 5-10% at best. To achieve higher efficiency, new thermoelectric materials with a higher figure of merit need to be discovered or designed by using advanced techniques such as band structure engineering, nanostructuring, doping, alloying, or heterostructure.

High cost: The cost of thermoelectric generators is mainly determined by the cost of the thermoelectric materials and modules. Current thermoelectric materials are often composed of rare or toxic elements that are expensive or difficult to obtain. The fabrication of thermoelectric modules also requires sophisticated processes and equipment that increase the cost. To reduce the cost of thermoelectric generators, alternative materials that are abundant, cheap, and environmentally friendly need to be developed or discovered. The fabrication of thermoelectric modules also needs to be simplified and scaled up to reduce the manufacturing cost and increase the production rate.

Thermal management: The performance of thermoelectric generators depends on the temperature difference between the hot and cold sides of the module. Therefore, efficient heat transfer and dissipation are essential for achieving high power output and reliability. The heat source and the heat sink need to be properly designed and matched with the thermoelectric module to ensure optimal heat flow and temperature distribution. The thermal contact resistance between the module and the heat source or sink also needs to be minimized to reduce thermal losses. The thermoelectric materials and modules also need to withstand high temperatures and thermal stresses without degradation or failure.

System integration: Thermoelectric generators are not standalone devices but rather components of a larger system that includes other elements, such as heat exchangers, electrical converters, controllers, sensors, and batteries. The integration of these elements into a coherent and functional system requires careful design and optimization of various parameters, such as electrical impedance, voltage regulation, power conditioning, load matching, and system control. The system integration also needs to consider the specific application requirements, such as size, weight, cost, durability, safety, and environmental impact.

The future directions for thermoelectric generator research and development include:

Novel thermoelectric materials: The discovery or design of novel thermoelectric materials with a high figure of merit is the key to improving the efficiency and competitiveness of thermoelectric generators. Novel thermoelectric materials can be obtained by using advanced techniques such as band structure engineering, nanostructuring, doping, alloying, or heterostructure to manipulate the electronic and phononic properties of the materials. Novel thermoelectric materials can also be obtained by exploring new classes of materials, such as organic, hybrid, or topological materials, that may exhibit unconventional or enhanced thermoelectric effects.

Advanced thermoelectric modules: The development of advanced thermoelectric modules with improved performance and reliability is another important aspect of thermoelectric generator research and development. Advanced thermoelectric modules can be achieved by using novel thermoelectric materials with high figures of merit or by using novel module architectures or configurations that can increase power output or reduce thermal losses. Advanced thermoelectric modules can also be achieved by using novel fabrication methods or techniques that can reduce the cost or increase the quality of the modules.

Innovative thermoelectric systems: The innovation of thermoelectric systems with novel designs and applications is a promising direction for thermoelectric generator research and development. Innovative thermoelectric systems can be achieved by using novel heat sources or sinks that can provide high or stable temperature differences or by using novel integration schemes or strategies that can optimize the system’s performance or functionality. Innovative thermoelectric systems can also be achieved by exploring new application domains or scenarios that can benefit from the advantages of thermoelectric generators.

Conclusion

Thermoelectric generators are devices that can convert heat energy into electrical energy using the Seebeck effect. Thermoelectric generators have many advantages over conventional power generation methods, such as compactness, reliability, noiselessness, and direct conversion. Thermoelectric generators have various applications in different fields, such as cooling devices, power generation from waste heat, and power generation from radioisotopes. However, thermoelectric generators also face some challenges and limitations that need to be overcome for practical implementation, such as low efficiency, high cost, thermal management, and system integration. The future directions for thermoelectric generator research and development include novel thermoelectric materials, advanced thermoelectric modules, and innovative thermoelectric systems. Thermoelectric generators have great potential for energy conversion and harvesting applications in various sectors and scenarios.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Blake is an electrical engineering leader with 20+ years of expertise in imaging technology innovation. Former CTO of a global scientific camera manufacturer, he now drives strategic R&D and CCD-to-CMOS transitions at Jingtu Optoelectronics. His career combines technical excellence in precision instrumentation with cross-disciplinary team leadership across global markets.