Busbars and Connectors in HV and EHV installations

What is an Electric Busbar?

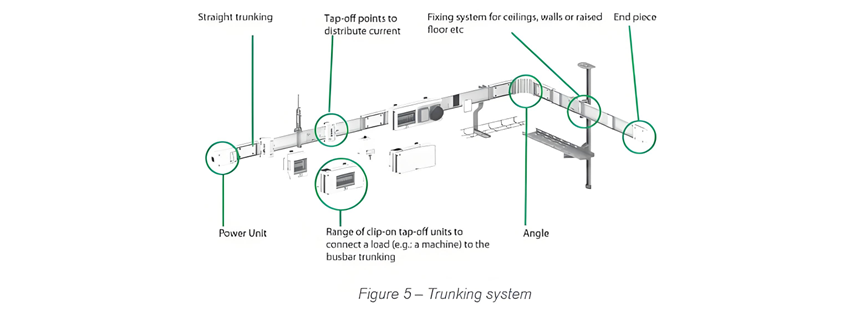

Widely used in data centers and industrial plants for high-current power distribution, these systems enable flexible layout and easy expansion through modular design.

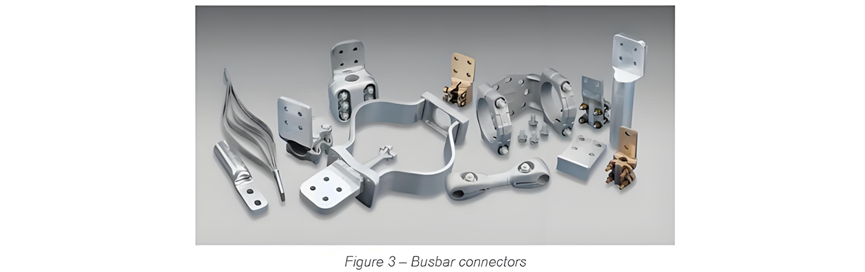

For copper-copper connections, bronze connectors are used; for aluminium-aluminium connections, aluminium alloy connectors should be applied; and for copper-aluminium connections, bi-metallic connectors are mandatory to prevent corrosion caused by electrolytic effects.

Insulated Busbars & Trunking Systems

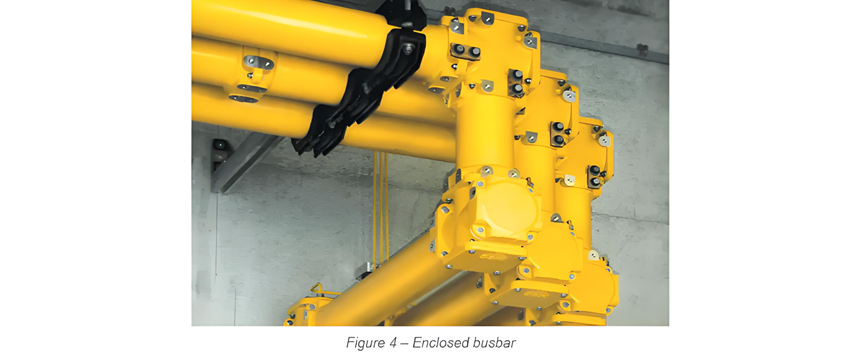

In indoor medium-voltage (MV) and low-voltage (LV) installations—particularly where high currents and limited space coexist—busbars are often enclosed in metallic casings for mechanical protection and insulation.This design reduces busbar heat dissipation due to restricted air flow and radiation losses, resulting in current ratings significantly lower than those for free-air installations. Ventilated enclosures can be used to minimize current derating.

Technical Details Analysis

- Electrochemical Protection for Different Material Connections

- Copper-copper joints: Bronze connectors (tin bronze or aluminium bronze) enhance contact reliability via solid solution strengthening, preventing pure copper creep relaxation.

- Aluminium-aluminium joints: 6061-T6 aluminium alloy connectors undergo aging treatment to ensure oxide film stability.

- Copper-aluminium transitions: Bi-metallic connectors use explosive welding or brazing (e.g., copper-aluminium composite bars) to block electrochemical corrosion paths.

- Thermal Management Challenges in Enclosed Busbars

Thermal resistance analysis: Air gaps formed by enclosures reduce thermal conductivity by 30%-50%.

Compensation solutions:

- Forced air cooling: Internal fans increase current-carrying capacity by 20%-30%.

- Enclosure cooling fins: Enhanced surface area for natural convection.

- High thermal conductivity insulation: Silicone rubber coatings to reduce thermal resistance.

- Engineering Application Specifications

- Protection class: Typically IP54 for indoor environments, upgraded to IP65 in humid conditions.

- Short-circuit withstand: Compliant with IEC 61439 dynamic and thermal stability requirements.

- Expansion compensation: Expansion joints every 30-50 meters to accommodate thermal deformation.

Widely used in data centers and industrial plants for high-current power distribution, these systems enable flexible layout and easy expansion through modular design.

Isolated Busbars

Isolated busbars typically consist of copper or aluminium flat bars (one or more per phase, sized according to current requirements), with each phase enclosed in a separately earthed sheath. The sheath ends are connected by short-circuit rated bars capable of carrying full fault currents.The sheath primarily prevents inter-phase short circuits. Additionally, it cancels out magnetic fields generated by conductor currents: an equal and opposite current induced in the sheath neutralizes the electromagnetic field almost completely.Common insulating media include air and SF₆.