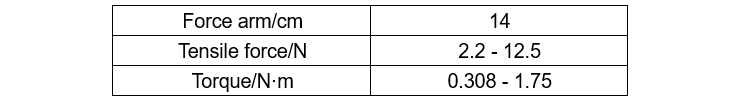

Torque Calculation Basis and Design Criteria

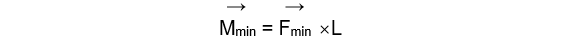

Based on the structural characteristics of the linkage operating handle, the torque requirement for manual closing of the circuit breaker can be derived by determining the length of the force arm and the pulling force parameters. According to the mechanical formula

- L→ is the distance vector from the rotation axis of the operating handle to the force application point, with an average measured value of 14 cm;

- F→min is the minimum vector force required to drive the rotating rod;

- M→min is the minimum torque required to initiate rotation of the rod.

Through operational characteristic analysis, the rotational resistance of the manually operated circuit breaker reaches its peak at the 15th rotation cycle. The minimum torque data at this point can cover the entire closing process. The torque design of the remote closing device must exceed this critical value with a safety margin to accommodate torque variations among different circuit breaker models. Detailed test data will be presented in subsequent sections.

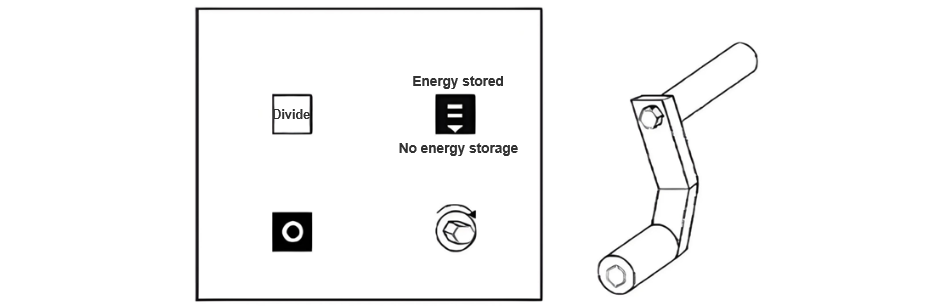

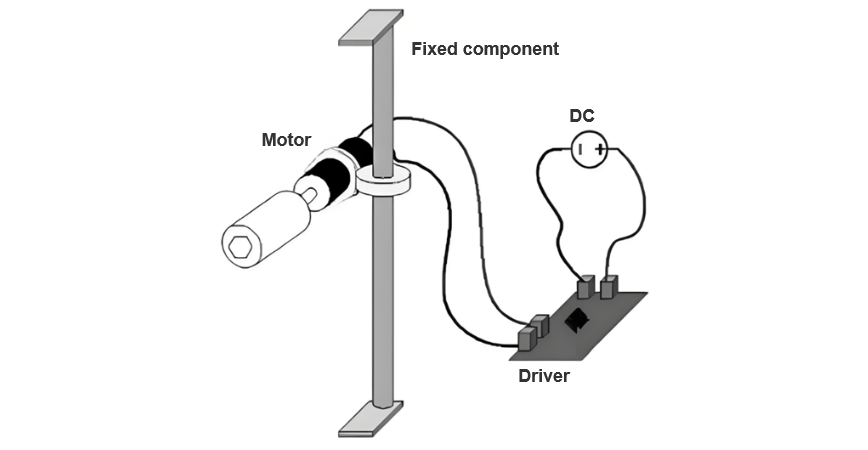

Basic Structure of the Remote Closing Device

As shown in Figure 2, the device consists of a fixed rod, moving components, electric device, and closing joint. The fixed rod is designed to be telescopic, with support plates welded on both sides. During installation, the rod is first shortened and placed vertically into the cabinet, then extended to make the support plates prop against the cabinet for horizontal fixation. The moving components are adjusted in the vertical direction to align the closing joint of the electric device with the rotating head of the handcart switch. After configuration, operators can withdraw to a safe area and send a clockwise signal via the remote transmitter to complete the closing operation.

Realization of Remote Control and Operation

Motor Selection and Parameters

In selecting the core motor module, permanent magnet DC brushless motors and brushed motors were compared. Brushless motors offer significant advantages in service life and noise level (≤55dB), but feature complex control circuits and higher costs (40% more than brushed types). Given the device's non-stringent requirements for motor control, the XD-3420 permanent magnet DC brushed motor was chosen for its simple control and low cost. Key parameters:

- Rated voltage: 12V; Rated current: 2.42A;

- Rated power: 30W; Calculated rated torque: 11.9N·m (1.19kgf·cm), meeting operational requirements.

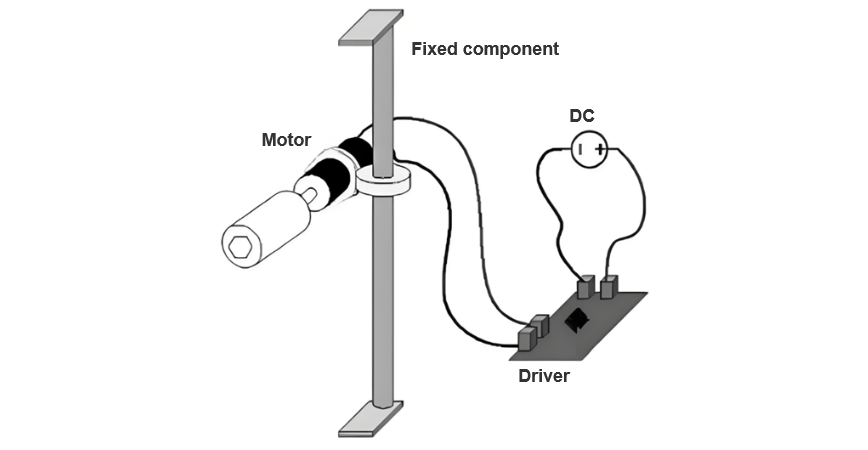

To enable maintenance personnel to operate from a safe distance, the device employs a Qichip QA-R-010 wireless remote control switch for wireless power management. The module consists of a transmitter and receiver: the receiver supports DC input from 3.6V to 24V, with red/black wires for positive/negative inputs and blue/gray wires for corresponding outputs (output voltage matches input). The two-button transmitter offers three output modes: momentary, latching, and interlocking. The project utilizes the momentary mode, where the switch module conducts only while the button is pressed, ensuring instant disconnection upon release to meet the requirements of transient control during closing operations.

On-site remote control experiment

We used a tensile tester to measure the pulling force required for manual closing of a decommissioned hand - cranked handcart switch. As shown in Table 1, when the hand - cranked closing reaches around the 15th circle, the minimum pulling force needed for hand - cranked closing reaches its maximum value. Using this pulling force, we calculated that the minimum torque required for the entire hand - cranked closing process is 1.75 N·m.

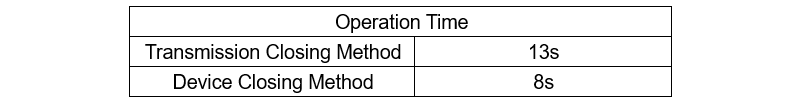

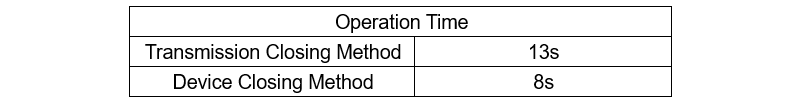

We compared the operation times of the traditional manual closing method and the remote closing device. Table 2 shows that using the remote closing device not only avoids risks but also slightly improves operation efficiency compared to pure manual operation. Without increasing time costs, it significantly reduces operators' safety risks.

To address the safety risk of maintenance personnel needing to operate old - fashioned hand - cranked circuit breakers up close in the current distribution network, we proposed and developed an auxiliary device. It allows maintenance personnel to keep a distance from the switchgear and remotely control the circuit breaker closing. We detailed the basic software and hardware components of the prototype and its usage. Torque tests show that this remote closing auxiliary device meets the closing torque requirements of hand - cranked circuit breakers. Compared with the traditional operation method, the operation time is similar. It avoids the risks of maintenance personnel operating such circuit breakers up close without increasing time costs, and the device has good engineering application value.