What is Electrical Insulator Testing?

What is Electrical Insulator Testing?

Electrical Insulator Definition

An electrical insulator is defined as a device that resists the flow of electric current, providing protection and ensuring safety in electrical systems.

Causes of Insulator Failure

Cracking, defective materials, porosity, improper glazing, flashover, and mechanical stress are primary causes of insulator failure.

Testing of Insulators

Flashover tests of insulator

Power Frequency Dry Flashover Test of Insulator

First the insulator to be tested is mounted in the manner in which it would be used practically.

Then terminals of variable power frequency voltage source are connected to the both electrodes of the insulator.

Now the power frequency voltage is applied and gradually increased up to the specified value. This specified value is below the minimum flash over voltage.

This voltage is maintained for one minute and observe that there should not be any flash-over or puncher occurred.

The insulator must be capable of sustaining the specified minimum voltage for one minute without flash over.

Power Frequency Wet Flashover Test or Rain Test of Insulator

In this test also the insulator to be tested is mounted in the manner in which it would be used practically.

Then terminals of variable power frequency voltage source are connected to the both electrodes of the insulator.

After that the insulator is sprayed with water at an angle of 45o in such a manner that its precipitation should not be more 5.08 mm per minute. The resistance of the water used for spraying must be between 9 kΩ 10 11 kΩ per cm3 at normal atmospheric pressure and temperature. In this way we create artificial raining condition.

Now the power frequency voltage is applied and gradually increased up to the specified value.

This voltage is maintained for either one minute or 30 second as specified and observe that there should not be any flash-over or puncher occurred. The insulator must be capable of sustaining the specified minimum power frequency voltage for specified period without flash over in the said wet condition.

Power Frequency Flash over Voltage test of Insulator

The insulator is kept in similar manner of previous test.

In this test the applied voltage is gradually increased in similar to that of previous tests.

But in that case the voltage when the surroundings air breaks down, is noted.

Impulse Frequency Flash over Voltage Test of Insulator

The overhead outdoor insulator must be capable of sustaining high voltage surges caused by lightning etc. So this must be tested against the high voltage surges.

The insulator is kept in similar manner of previous test.

Then several hundred thousands Hz very high impulse voltage generator is connected to the insulator.

Such a voltage is applied to the insulator and the spark over voltage is noted.

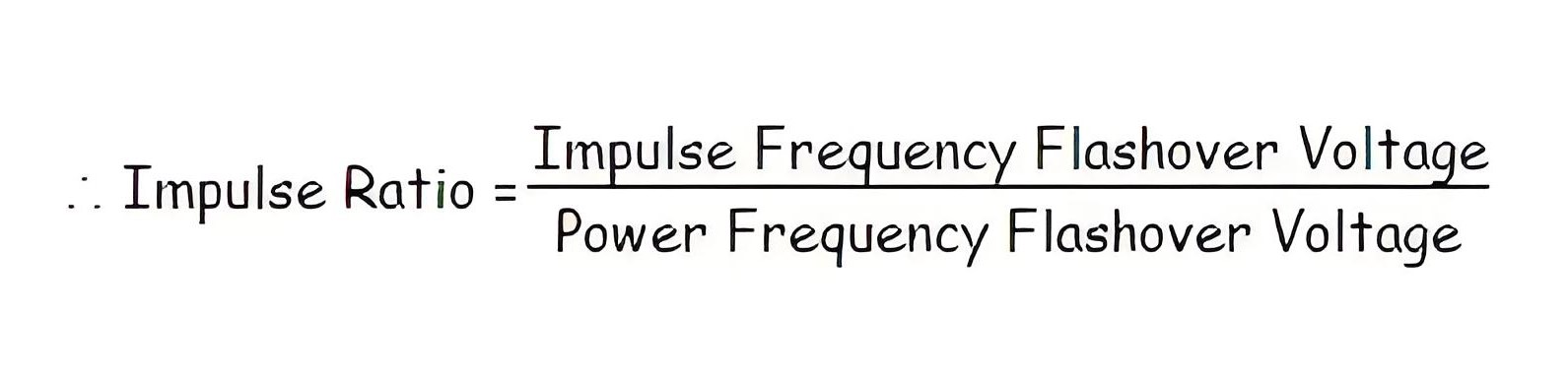

The ratio of this noted voltage to the voltage reading collected from power frequency flash over voltage test is known as impulse ratio of insulator.

This ratio should be approximately 1.4 for pin type insulator and 1.3 for suspension type insulators.

Performance tests

Temperature Cycle Test of Insulator

The insulator is first heated in water at 70oC for one hour.

Then this insulator immediately cooled in water at 7oC for another one hour.

This cycle is repeated for three times.

After completion of these three temperature cycles, the insulator is dried and the glazing of insulator is thoroughly observed.

After this test there should not be any damaged or deterioration in the glaze of the insulator surface.

Puncture Voltage Test of Insulator

The insulator is first suspended in an insulating oil.

Then voltage of 1.3 times of flash over voltage, is applied to the insulator.

Porosity Test of Insulator

The insulator is first broken into pieces.

Then These broken pieces of insulator are immersed in a 0.5 % alcohol solution of fuchsine dye under pressure of about 140.7 kg ⁄ cm2 for 24 hours.

After that the sample are removed and examine.

Mechanical Strength Test of Insulator

The insulator is applied by 2½ times the maximum working strength for about one minute.

The insulator must be capable of sustaining this much mechanical stress for one minute without any damage in it.

Routine tests

Each of the insulator must undergo the following routine test before they are recommended for using at site.

Proof Load Test of Insulatot

In proof load test of insulator, a load of 20% in excess of specified maximum working load is applied for about one minute to each of the insulator.

Corrosion Test of Insulator

The insulator with its galvanized or steel fittings is suspended into a copper sulfate solution for one minute.

Then the insulator is removed from the solution and wiped, cleaned.

Again it is suspended into the copper sulfate solution for one minute.

4.The process is repeated for four times.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.