What are Flexible AC Transmission Systems ?

What are Flexible AC Transmission Systems ?

FACTS Definition

Flexible AC Transmission Systems (FACTS) are defined as systems that use power electronics to improve the control and power transfer in AC transmission networks.

Features of FACTS

Fast voltage regulation

Increased power transfer over long AC lines

Damping of active power oscillations

Load flow control in meshed systems

Thereby significantly improving the stability and performance of existing and future transmission systems.With Flexible AC Transmission Systems (FACTS), power companies can better utilize existing networks, increase the availability and reliability of their lines, and improve dynamic and transient network stability, ensuring a better quality of supply.

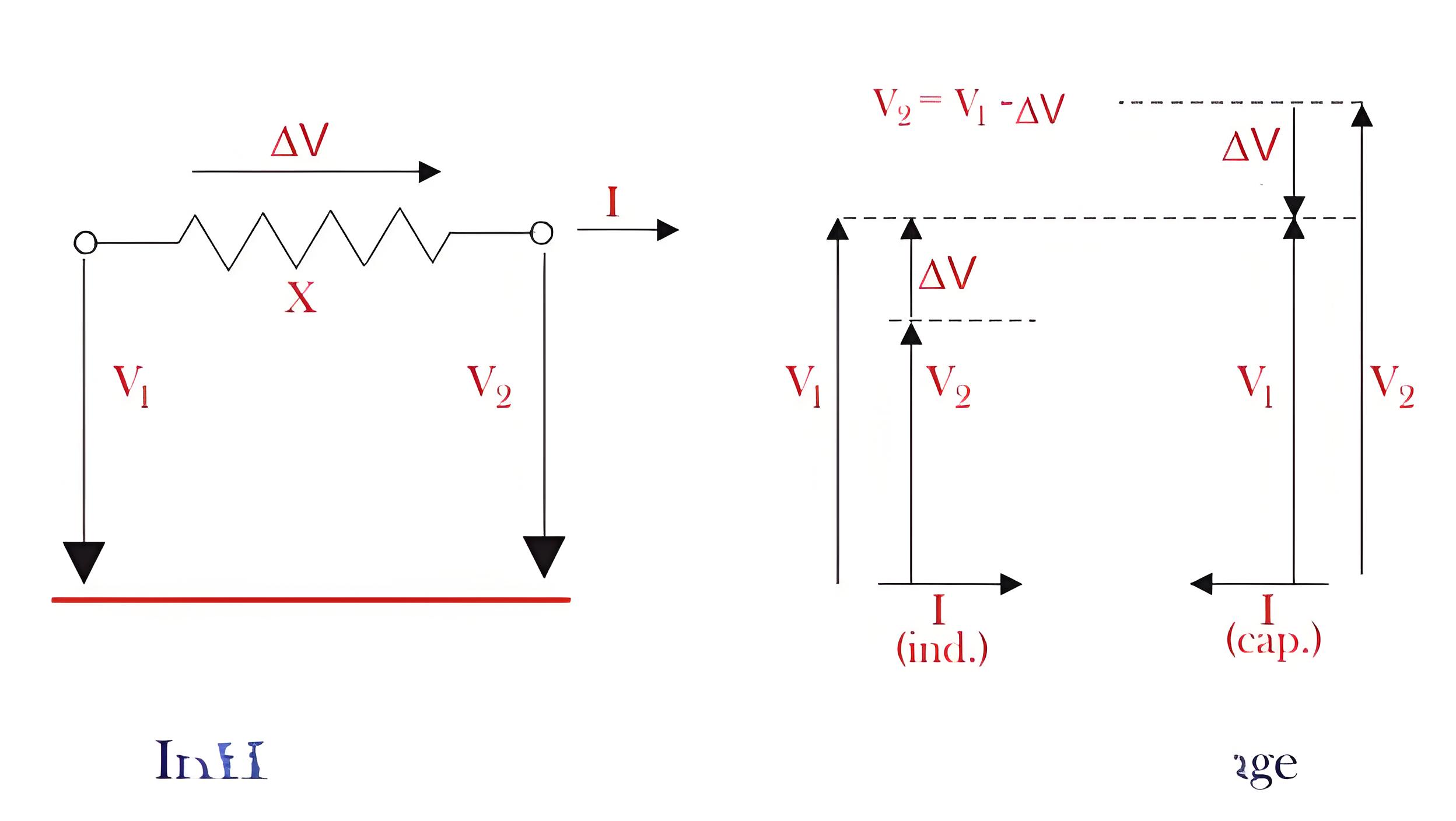

Influence of Reactive Power Flow on Power System Voltage

Reactive Power Compensation

Consumer loads need reactive power that varies continuously, increasing transmission losses and affecting voltage in the network. To prevent high voltage fluctuations or power failures, this reactive power must be balanced. Passive components like reactors or capacitors can supply inductive or capacitive reactive power. Fast and precise reactive power compensation, using thyristor-switched and thyristor-controlled components, can improve transmission efficiency and control, replacing slower mechanical switches.

Effects of Reactive Power Flow

Reactive power flow has the following effects:

Increase in transmission system losses

Adding to power plant installations

Adding to operating costs

Major influence on system voltage deviation

Degradation of load performance at under voltage

Risk of insulation breakdown at over-voltage

Limitation of power transfer

Steady-state and dynamic stability limits

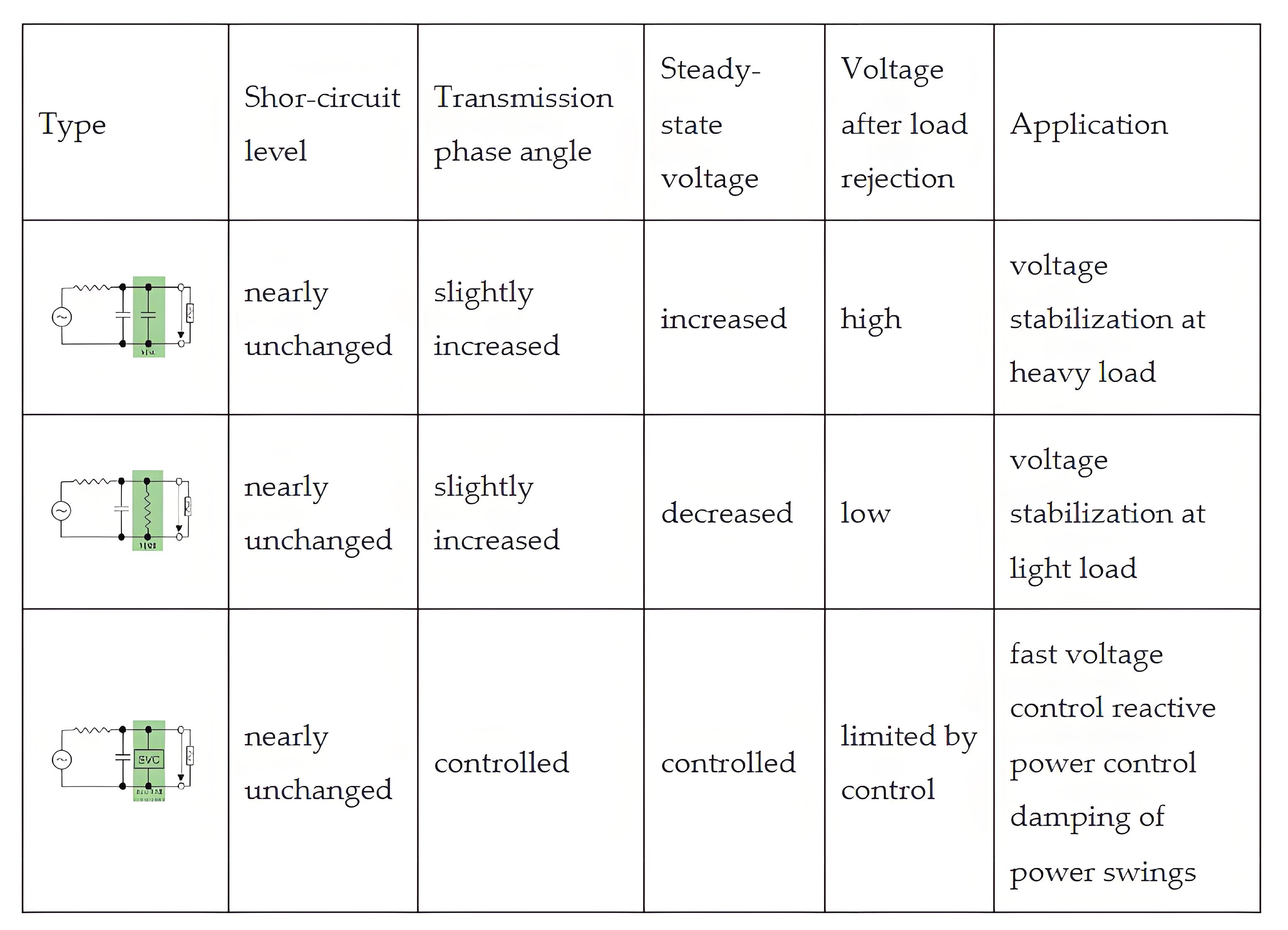

Parallel and Series

Fig. Shows today’s most common shunt compensation devices, their influence on the most important transmission parameters, and typical applications.

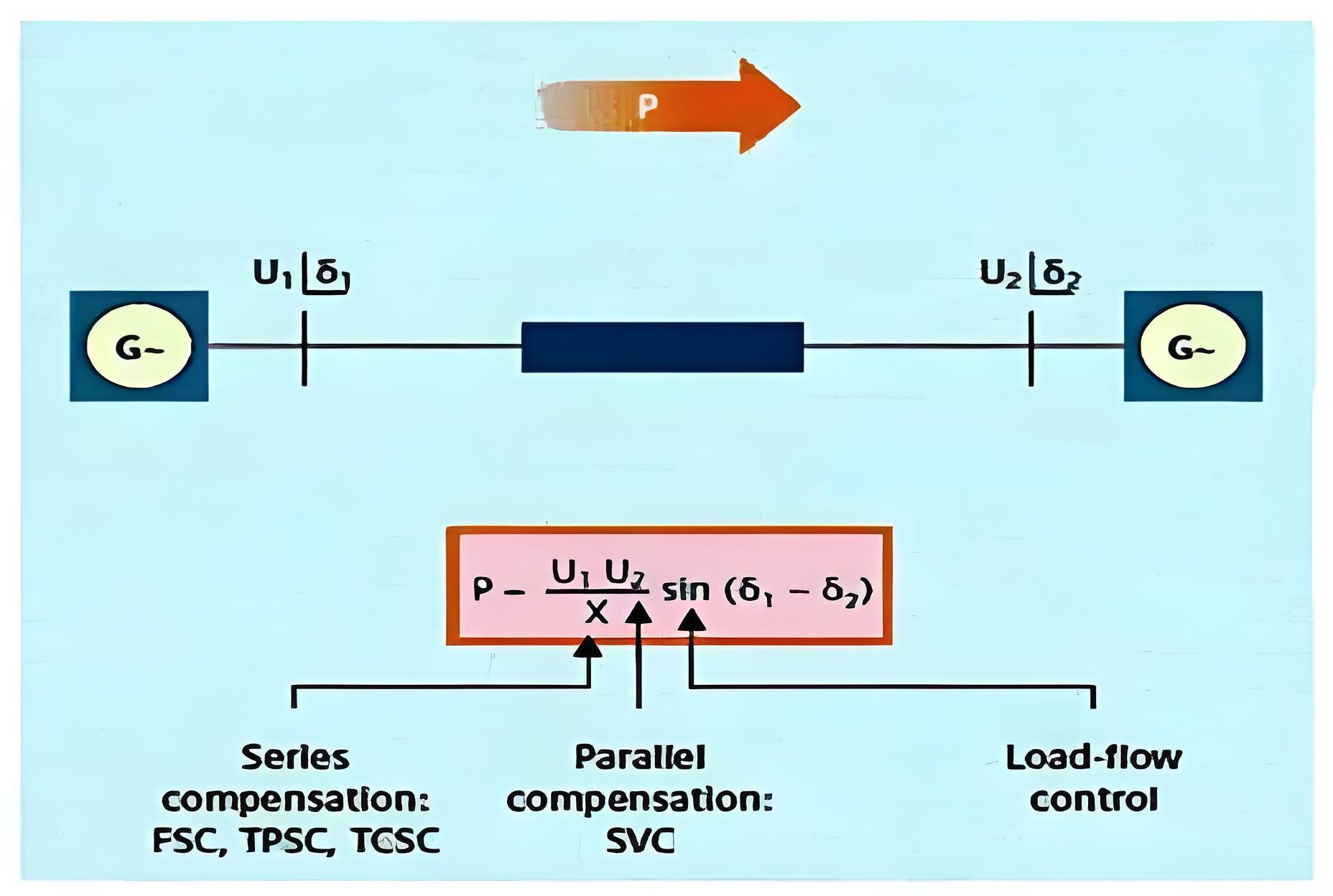

Fig.: The active power/ transmission angle equation illustrates which FACTS components selectively influence which transmission parameters.

Protection and Control Systems

To improve redundancy management, special modules were developed to supplement the SIMATIC TDC automation system. These modules issue triggering signals to thyristor valves and take up less space than previous technology.

SIMATIC TDC’s flexible interface design allows it to replace existing systems easily. This integration can be done with minimal delay, ensuring measured values from old systems are processed by the new control system. The space efficiency of SIMATIC TDC also allows parallel configuration with existing systems.

Human Machine Interface.The interface between the operator and the plant .(HMI = Human Machine Interface) is the standardized.SIMATIC Win CC visualization system, which further simplifies operation and facilitates the adaptation of graphical user interfaces to the operator’s requirements.

Hardware for Control and Protection

Siemens offers the latest in control and protection for FACTS – the tried and tested SIMATIC TDC (Technology and Drive Control) automation system. SIMATIC TDC is used worldwide in almost every industry and has been proven in both production and process engineering as well as in many HVDC and FACTS applications.

Operating personnel and project planning engineers work exclusively with a standardized, universal hardware and software platform, enabling them to perform demanding tasks more rapidly. One of the main considerations in developing this automation system was to ensure the highest degree of availability of the FACTS – which is why all control and protection systems, as well as the communication links, are configured redundantly (if requested by the customer).

The new instrumentation and control technology also permits the use of a high-performance fault recorder operating at a 25 kHz sampling rate. New instrumentation and control technology reduces the period between fault recording and the printout of the fault report from several minutes (previously) to 10 seconds (now).

Converter for FACTS

LTT – Light Triggered Thyristors

Thyristors control passive components in reactive power compensation systems. Siemens’ direct light triggering system activates thyristors with a 10-microsecond light pulse at 40 milliwatts. This device includes overvoltage protection, making it self-protecting if forward voltage exceeds limits.

The light pulse travels through fiber optics from the valve control to the thyristor gate. Conventional systems use electrically triggered thyristors, requiring pulses of several watts generated by nearby electronic equipment. Direct light triggering reduces electrical components in the thyristor valve by 80%, improving reliability and electromagnetic compatibility. Additionally, the new thyristor technology ensures long-term availability of electronic components for at least 30 years.

Thyristor valves from Siemens are assembled from 4-inch or 5-inch thyristors, depending on the current- carrying capacity/rated current required. Thyristor technology has been under constant development since the early 1960s. At present, thyristors can safely and economically handle blocking voltages of up to 8-kilovolts and rated currents of up to 4,200 amperes.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.