Test for Thickness of Insulation of Power Cable

Definition of Insulation Thickness Test

A test to confirm the insulation and sheath thickness of power cables to ensure they meet specified standards.

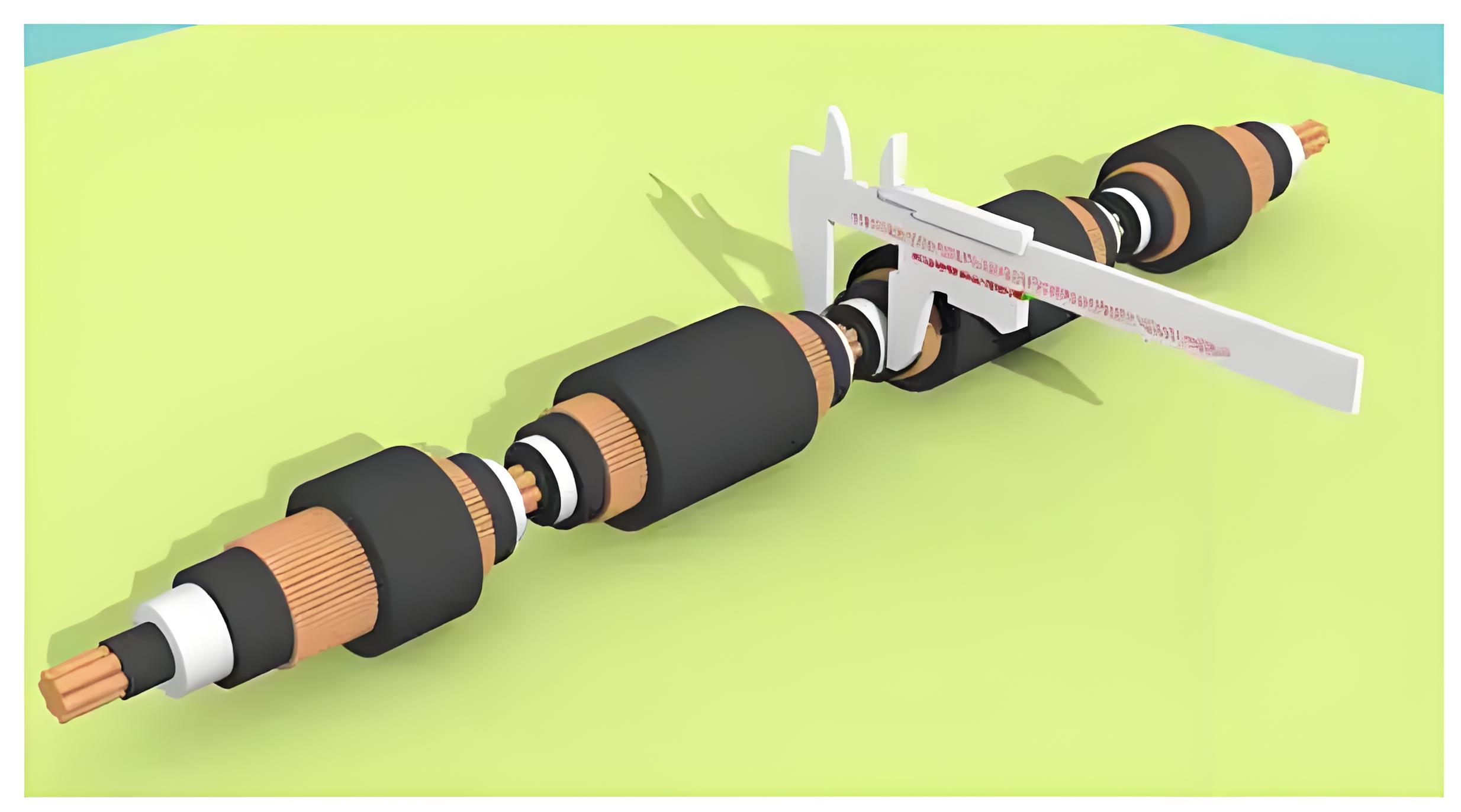

Apparatus required to test for thickness of insulation of Power Cable

This is purely a measurement process, hence the apparatus for the test are to be chosen very carefully. There should be, a micrometer gauge capable of measuring at least 0.01 mm variation, a vernier caliper which can clearly read at least 0.01 mm count, a measuring microscope with linear magnification of not less than 7 times and the possibility of reading at least to 0.01 mm, and a graduated magnifying glass can read clearly at least 0.01 mm.

First, prepare different specimens for each measuring instruments and method. There are two types of specimens: core cable pieces and slice pieces.

Specimen Preparation

Specimens are cut from the cable and prepared for different measurement techniques.

Procedure for testing of Thickness of Insulation of Power Cable

Use pieces at least 300 mm long for round conductors and outer sheaths. Cut specimens from the final product and remove all coverings without damaging the insulation or sheath. Use slice pieces for optical measurements, removing outer and inner materials if needed. Cut slices thinly along the plane perpendicular to the cable axis. Preferably take measurements at room temperature. Measure the core and insulated core diameters with a micrometer gauge or vernier caliper, perpendicular to the cable axis.

Take measurements at three equal intervals along the specimen, about 75 mm apart for a 300 mm piece. Measure the inner and outer diameters of the insulation or sheath at each point. For accuracy, take two measurements at each point, totaling six measurements for both inner and outer diameters. Calculate the average outer diameter and inner diameter from these measurements. The average radial thickness of the insulation or sheath is the difference between the average outer and inner diameters, divided by two.

If visual inspection shows eccentricity, use the optical method by taking a slice section of the specimen.

In the case of sliced section the specimen is placed under a measuring microscope along the optical axis. For circular specimen 6 such measurements are taken along the periphery at a regular interval. For noncircular conductor, such measurement is done radially at each point where the thickness of insulation appears minimum. The numbers of slices are taken from a specimen at regular interval along its length in such a manner that the total of such measurement would be not less than 18. For example, in case of circular conductor, at least 3 slices are taken from a specimen and 6 measurements in each slice to be carried out. In case of noncircular conductor, the number of slices taken from a specimen depends upon the number of points of minimum thickness of insulation. As in this case measurement is only made at the minimum thickness points.

Cable Insulation Importance

Ensures the cable can safely handle voltage and mechanical stresses throughout its service life.

Calculation for Thickness of Insulation

For Core/Cable Piece

Where, Dout is the average of six measurements taken for outer diameter of the insulation/sheath. Where, Din is the average of six measurements taken for inner diameter of the insulation/sheath.

For Slice Piece – The average of 18 optical measurements is taken as the minimum thickness of insulation/sheath.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.