What is the Tensile Test of Conductors?

What is the Tensile Test of Conductors?

Tensile Test Definition

A tensile test measures the strength of a material by pulling it apart until it breaks.

Purpose of Tensile Test for Conductors

This test ensures that cable conductors, such as aluminium wires, are strong enough to handle the pulling forces they experience during installation and use.

Apparatus for Tensile Test

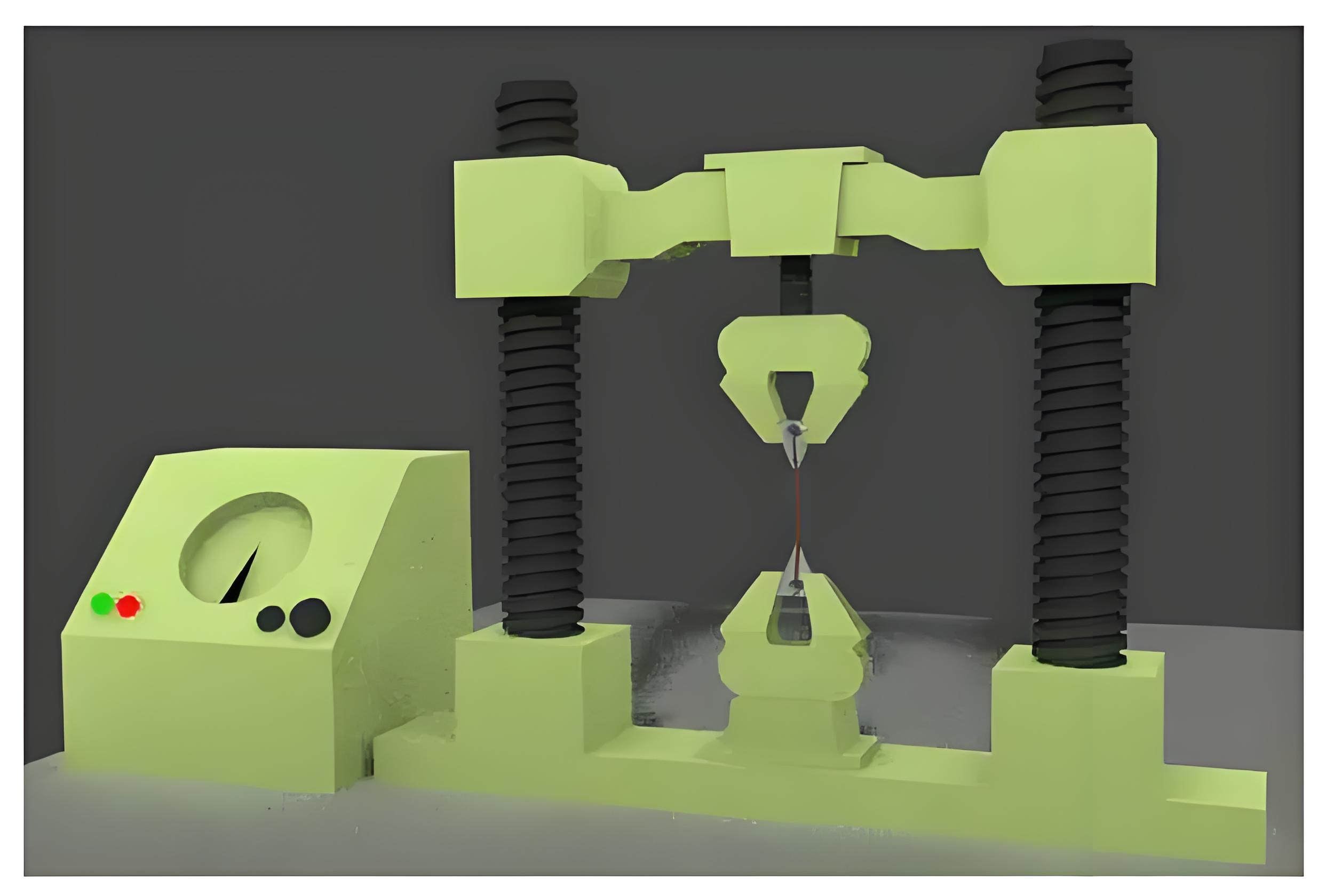

Tensile Testing Machine: An automatic machine, with two end grips properly designed to hold the conductor with sufficient strength so that the conductor cannot slid by any means during the test. The machine should have sufficient capacity to apply required tension during test.

Plane Faced Micrometer which can able to measure accurately even 0.01 mm variation. This is used to measure the diameter of the specimen conductor.

Suitable Scale with least scale division 1 mm to measure length of the specimen conductor.

Weighing Balance with sensitivity of 0.01g to measure mass of the specimen.

Method of Tensile Test of Conductors

A conductor specimen slightly longer than the gauge length (the length on which the test is done) is selected. Ensure the specimen has extra length at both ends for gripping by the tensile testing machine. No pre-conditioning of the specimen is needed.

Procedure of Tensile Test

The conductor specimen is fixed in the machine, and tension is applied gradually until the specimen fractures, noting the breaking load to calculate tensile strength.

Cable Tensile Test

This specific tensile test for cable conductors checks if the material meets the necessary tensile strength requirements for safe and effective use.

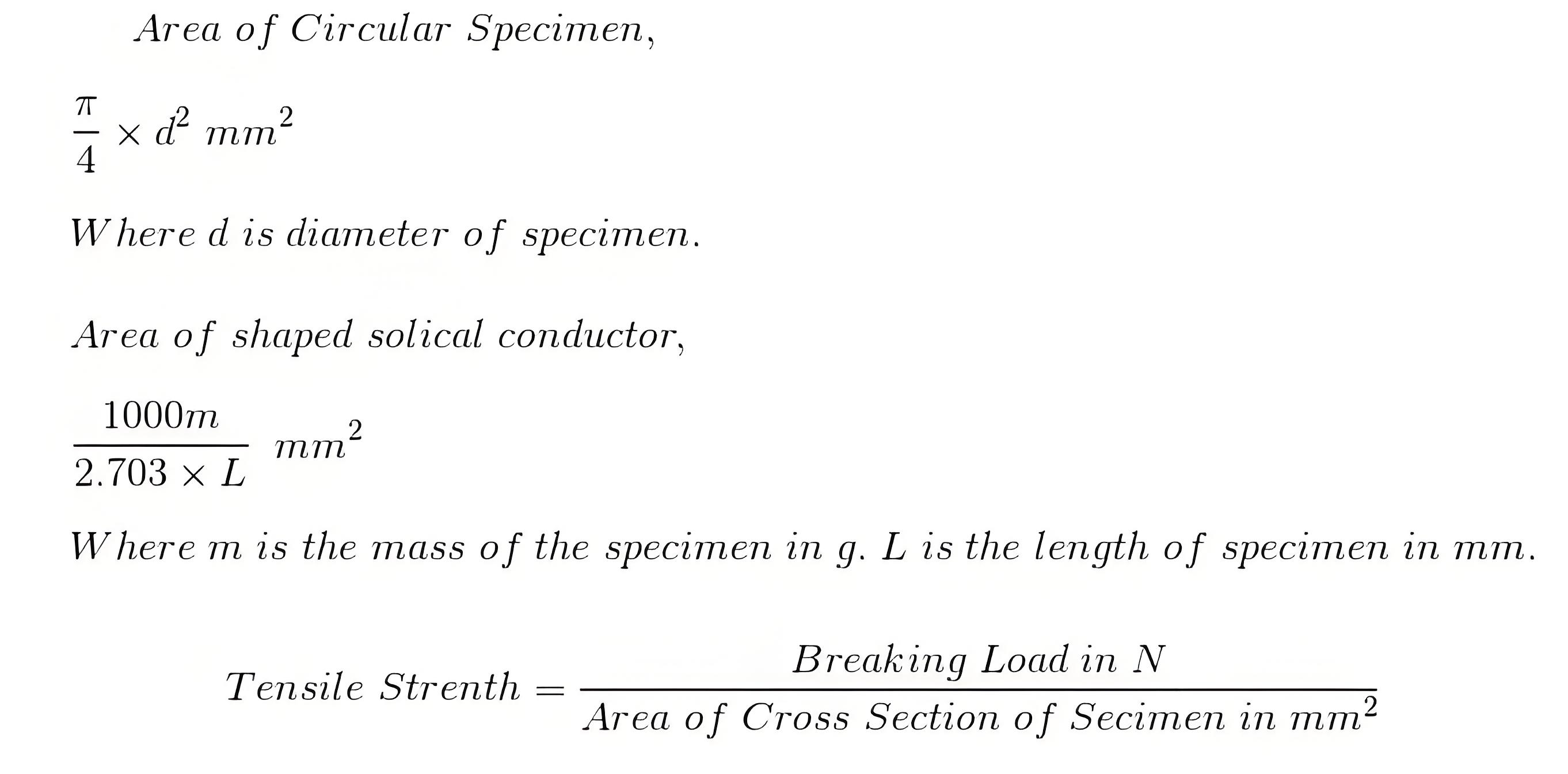

Calculation

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.