What is Tan Delta Test?

What is Tan Delta Test?

Tan Delta Test Definition

Tan delta is defined as the ratio of the resistive to capacitive components of electrical leakage current, indicating insulation health.

Principle of Tan Delta Test

When a pure insulator is connected between the line and earth, it acts like a capacitor. Ideally, if the insulating material, also serving as a dielectric, is 100% pure, the electric current passing through would only have a capacitive component, with no resistive component, due to zero impurities.

In a pure capacitor, the capacitive electric current leads the applied voltage by 90o.In reality, it’s impossible to achieve 100% purity in insulators. Over time, aging insulators accumulate impurities such as dirt and moisture. These impurities create a conductive path, introducing a resistive component to the leakage current from the line to earth.

Therefore, a low resistive component of leakage current indicates a good insulator. The health of an electrical insulator is gauged by the low ratio of resistive to capacitive components, known as tan delta or dissipation factor.

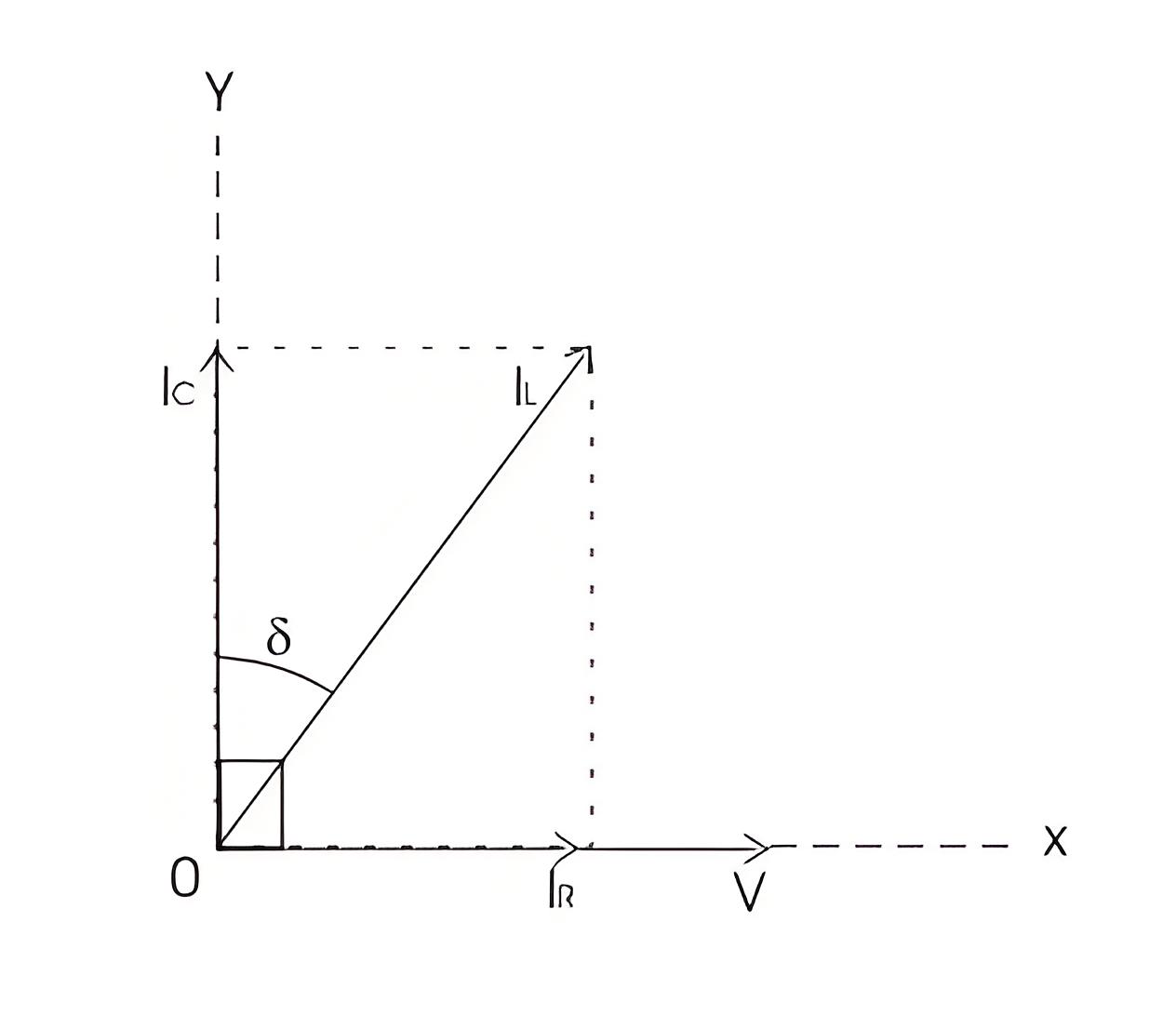

In the vector diagram above, the system voltage is drawn along the x-axis. Conductive electric current i.e. resistive component of leakage current, IR will also be along x-axis.

As the capacitive component of leakage electric current IC leads system voltage by 90o, it will be drawn along y-axis.

Now, total leakage electric current IL(Ic + IR) makes an angle δ (say) with y-axis.

Now, from the diagram above, it is cleared, the ratio, IR to IC is nothing but tanδ or tan delta.

NB: This δ angle is known as loss angle.

Method of Tan Delta Testing

The cable, winding, current transformer, potential transformer, transformer bushing, on which tan delta test or dissipation factor test to be conducted, is first isolated from the system. A very low-frequency test voltage is applied across the equipment whose insulation to be tested.

First, the normal voltage is applied. If the value of tan delta appears good enough, the applied voltage is raised to 1.5 to 2 times of normal voltage, of the equipment. The tan delta controller unit takes measurement of tan delta values. A loss angle analyzer is connected with tan delta measuring unit to compare the tan delta values at normal voltage and higher voltages and analyze the results.

During the test, it is essential to apply test voltage at a very low frequency.

Reason of applying Very Low Frequency

At higher frequencies, the capacitive reactance of an insulator drops, increasing the capacitive current component. Since the resistive component remains fairly constant, depending on the voltage and the insulator’s conductivity, the overall current amplitude also increases.

Therefore, required apparent power for tan delta test would become high enough which is not practical. So to keep the power requirement for this dissipation factor test, very low-frequency test voltage is required. The frequency range for tan delta test is generally from 0.1 to 0.01 Hz depending upon size and nature of insulation.

There is another reason for which it is essential to keep the input frequency of the test as low as possible.

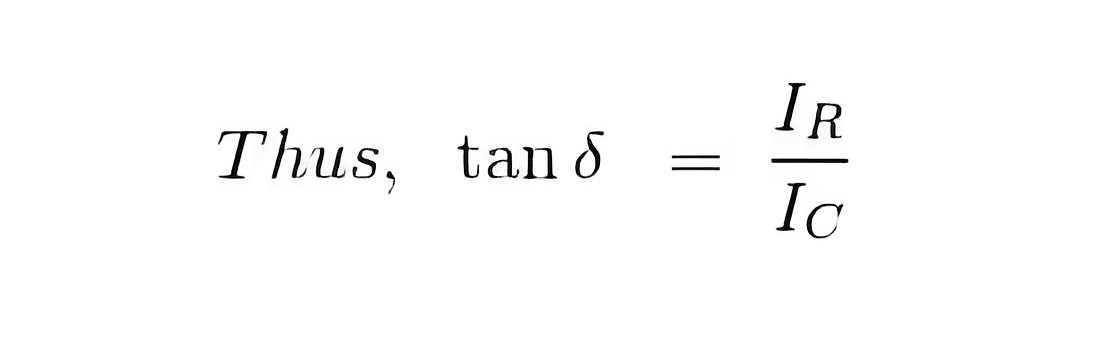

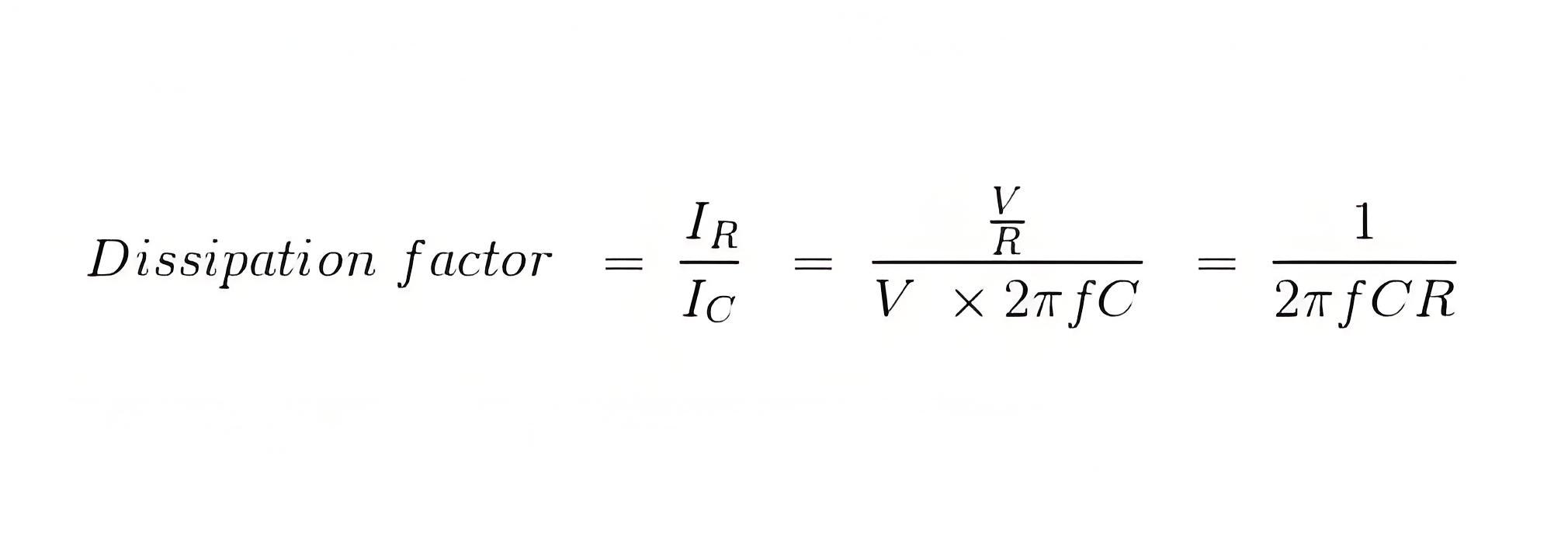

As we know,

That means, dissipation factor tanδ ∝ 1/f.Hence, at low frequency, the tan delta number is higher, and the measurement becomes easier.

How to Predict the Result of Tan Delta Testing

There are two ways to predict the condition of an insulation system during tan delta or dissipation factor test.

First, one is, comparing the results of previous tests to determine, the deterioration of the condition of insulation due to aging effect.

The second one is, determining the condition of insulation from the value of tanδ, directly. No requirement of comparing previous results of tan delta test.

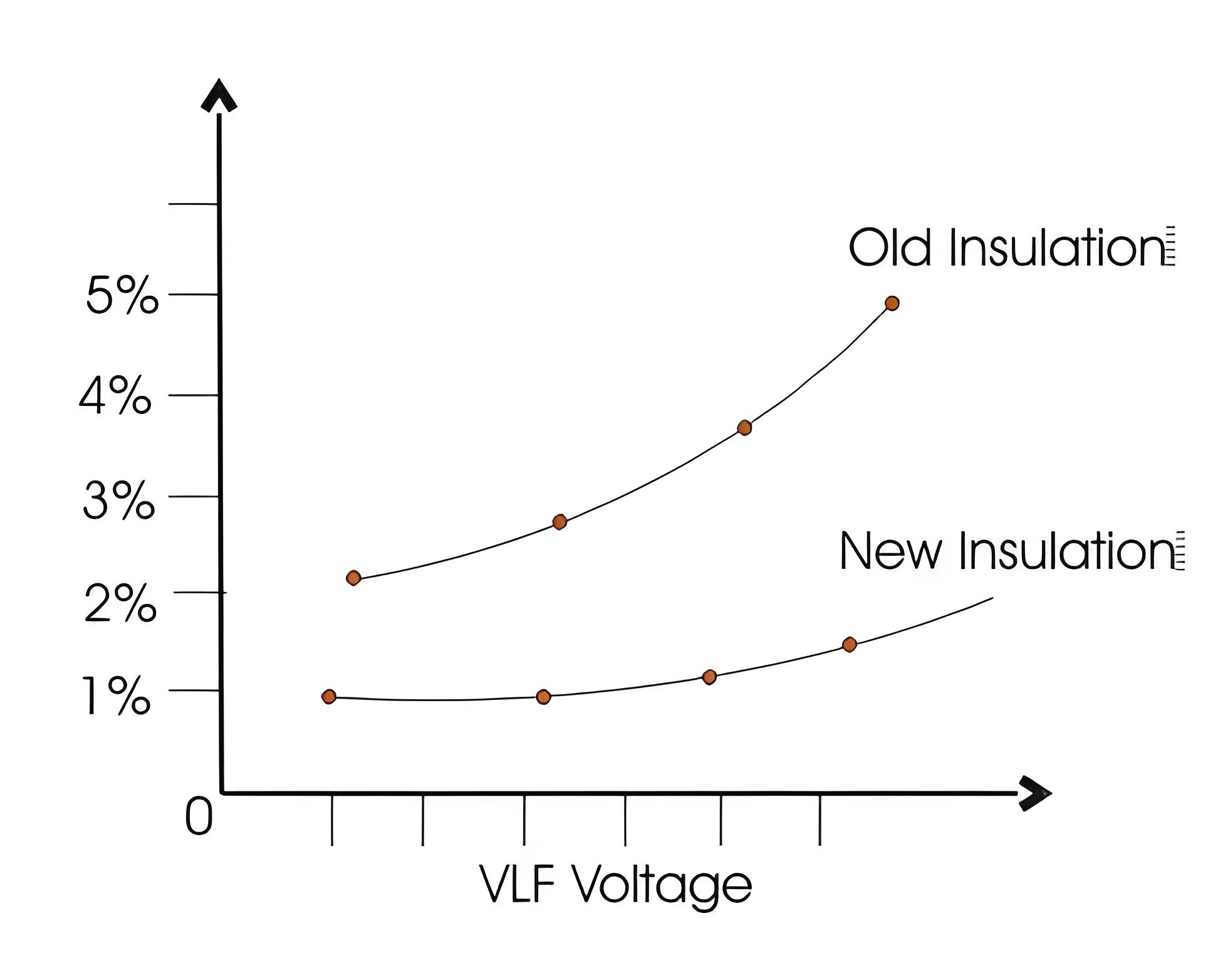

If the insulation is perfect, the loss factor will be approximately the same for all range of test voltages. But if the insulation is not sufficient, the value of tan delta increases in the higher range of test voltage.

From the graph, it is clear that the tan and delta number nonlinearly increases with increasing test very low-frequency voltage. The increasing tan&delta, means, high resistive electric current component, in the insulation. These results can be compared with the results of previously tested insulators, to take the proper decision whether the equipment would be replaced or not.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.