Loss evaluation in transformers based on IEC 60076

I. Definitions of Losses in IEC 6007

IEC 60076-1 (General Requirements) and IEC 60076-7 (Loading Guidelines) specify two core types of losses:

No-load Loss (P0)

Definition: Losses measured when the primary winding is energized at rated voltage and the secondary winding is open-circuited (dominated by core losses).

Test Conditions

- Measured at rated frequency and voltage (typically sinusoidal power frequency).

- Corrected to reference temperature (75°C for oil-immersed transformers, 115°C for dry-type).

Load Loss (Pk)

Definition: Losses measured when the secondary winding is short-circuited and rated current flows through the primary winding (dominated by copper losses).

Test Conditions:

- Measured at rated current and frequency.

- Corrected to reference temperature (75°C for oil-immersed; varies for dry-type based on insulation class).

II. Testing and Calculation of Losses

No-load Loss Test (IEC 60076-1 Clause 10)

Method

- Direct measurement using a power analyzer (instrument losses must be subtracted).

- Test voltage: rated voltage ±5%, with the lowest value used.

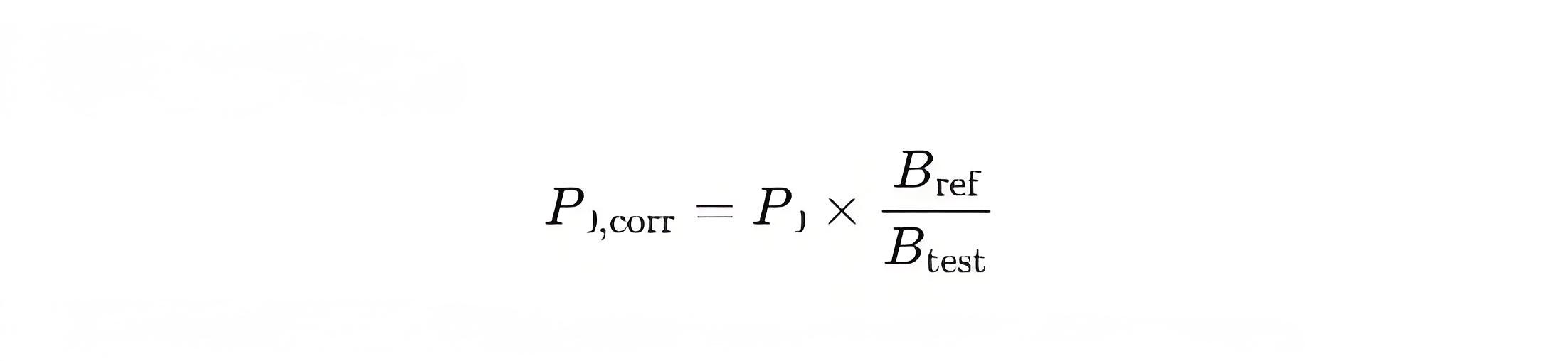

Temperature Correction Formula:

Bref: Flux density at reference temperature; B test : Measured flux density.

2. Load Loss Test (IEC 60076-1 Clause 11)

Method:

- Measured during short-circuit impedance testing.

- Test current: rated current; frequency deviation ≤ ±5%.

Temperature Correction Formula (for copper windings)

Tref: Reference temperature (75°C); T test : Winding temperature during testing.

Key Parameters and Tolerances

Loss Tolerances (IEC 60076-1 Clause 4.2):

- No-load loss: +15% allowed (measured value must not exceed guaranteed value).

- Load loss: +15% allowed (measured value must not exceed guaranteed value).

Stray Losses:

Losses caused by leakage flux in structural components, evaluated via high-frequency component separation or thermal imaging.

Energy Efficiency Classes and Loss Optimization

Per IEC 60076-14 (Energy Efficiency Guidelines for Power Transformers):

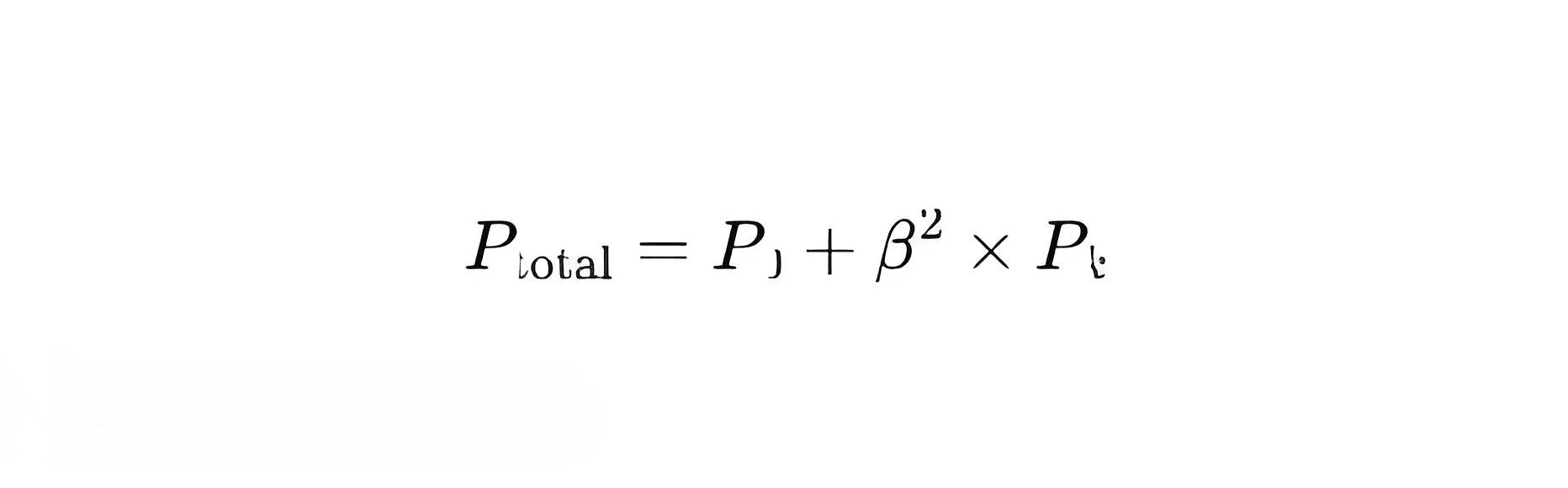

Total Losses (P total):

β: Load ratio (actual load / rated load).

Efficiency Classes (e.g., IE4, IE5) require total losses reduced by 10%~30%, achieved via:

- High-permeability silicon steel (reduces no-load losses).

- Optimized winding design (minimizes eddy current losses).

Practical Application Example

Case: 35kV Oil-Immersed Transformer (IEC 60076-7)

Rated Parameters:

- Capacity: 10 MVA

- Guaranteed no-load loss: 5 kW

- Guaranteed load loss: 50 kW (at 75°C).

Test Data:

No-load loss: 5.2 kW (within +15% tolerance → 5.75 kW limit).

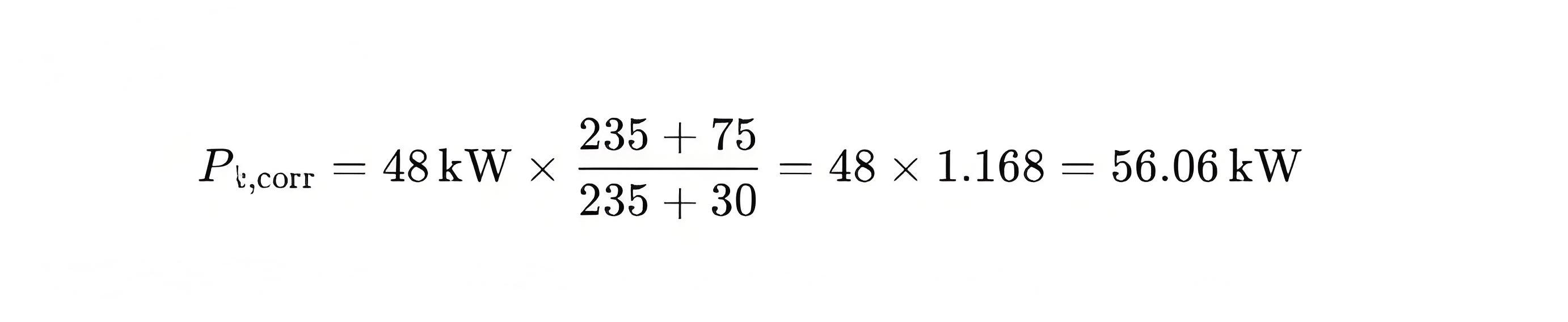

Load loss (tested at 30°C):

Conclusion: Load loss exceeds tolerance? Verify against 50 × 1.15 = 57.5 kW.

VI. Common Issues and Considerations

Ambient Temperature:

Tests must be conducted between -25°C to +40°C; corrections required outside this range.

Harmonic Losses:

Evaluate additional harmonic losses under non-sinusoidal loads per IEC 60076-18.

Digital Testing:

Use IEC 61869-calibrated sensors for accuracy.

Focused on the design of electrical equipment, proficient in electrical principles and relevant specifications, and skilled in using design software. From intelligent substations to various types of electrical equipment, I am adept at optimizing design solutions, integrating new technologies. With practical experience and collaborative management capabilities, I deliver outstanding electrical design achievements.