What is the difference between aluminum and silicon in terms of their use as semiconductors?

Differences Between Aluminum and Silicon in Semiconductor Applications

Aluminum and silicon have different applications in semiconductor technology, primarily due to their distinct physical and chemical properties and their specific roles in device fabrication. Here are the main differences between aluminum and silicon in semiconductor applications:

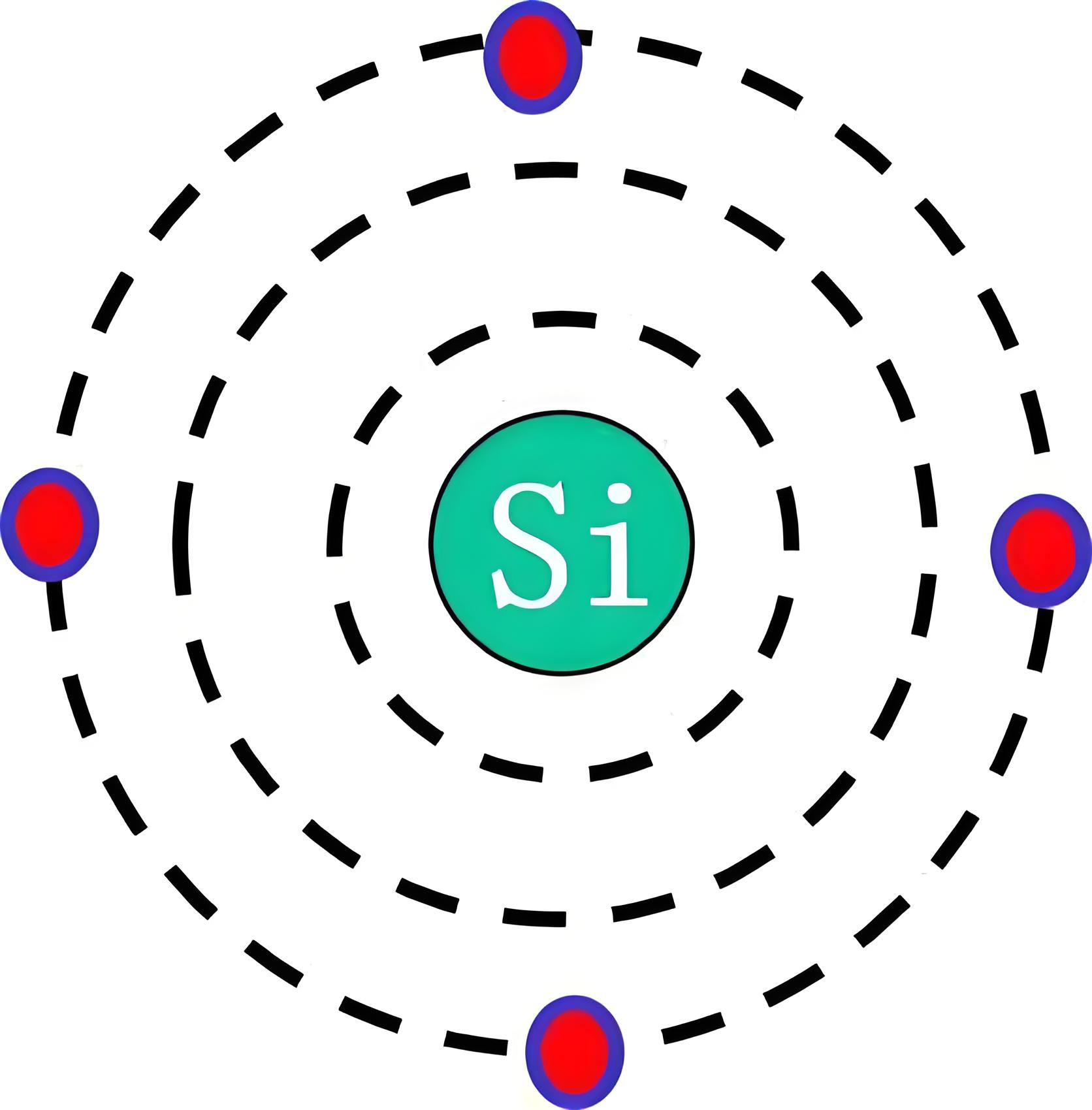

Silicon

Physical Properties:

Crystal Structure: Silicon typically exists in a single-crystal form, with the most common crystal structure being the diamond cubic structure.

Conductivity: Silicon is a typical semiconductor material, and its conductivity can be adjusted through doping (introducing impurity atoms).

Bandgap: Silicon has a bandgap of approximately 1.12 eV, making it suitable for electronic devices operating at room temperature.

Chemical Properties:

Oxidation: Silicon readily forms a dense layer of silicon dioxide (SiO₂) on its surface, which has excellent insulating properties and is widely used for insulation and passivation in semiconductor devices.

Stability: Silicon remains chemically stable at high temperatures, making it suitable for high-temperature processes.

Applications:

Integrated Circuits: Silicon is the primary material used in the manufacture of integrated circuits (ICs), including microprocessors, memory chips, and other logic circuits.

Solar Cells: Silicon-based solar cells are the most common and economical photovoltaic devices.

Sensors: Silicon-based sensors are widely used in various applications, such as pressure sensors and temperature sensors.

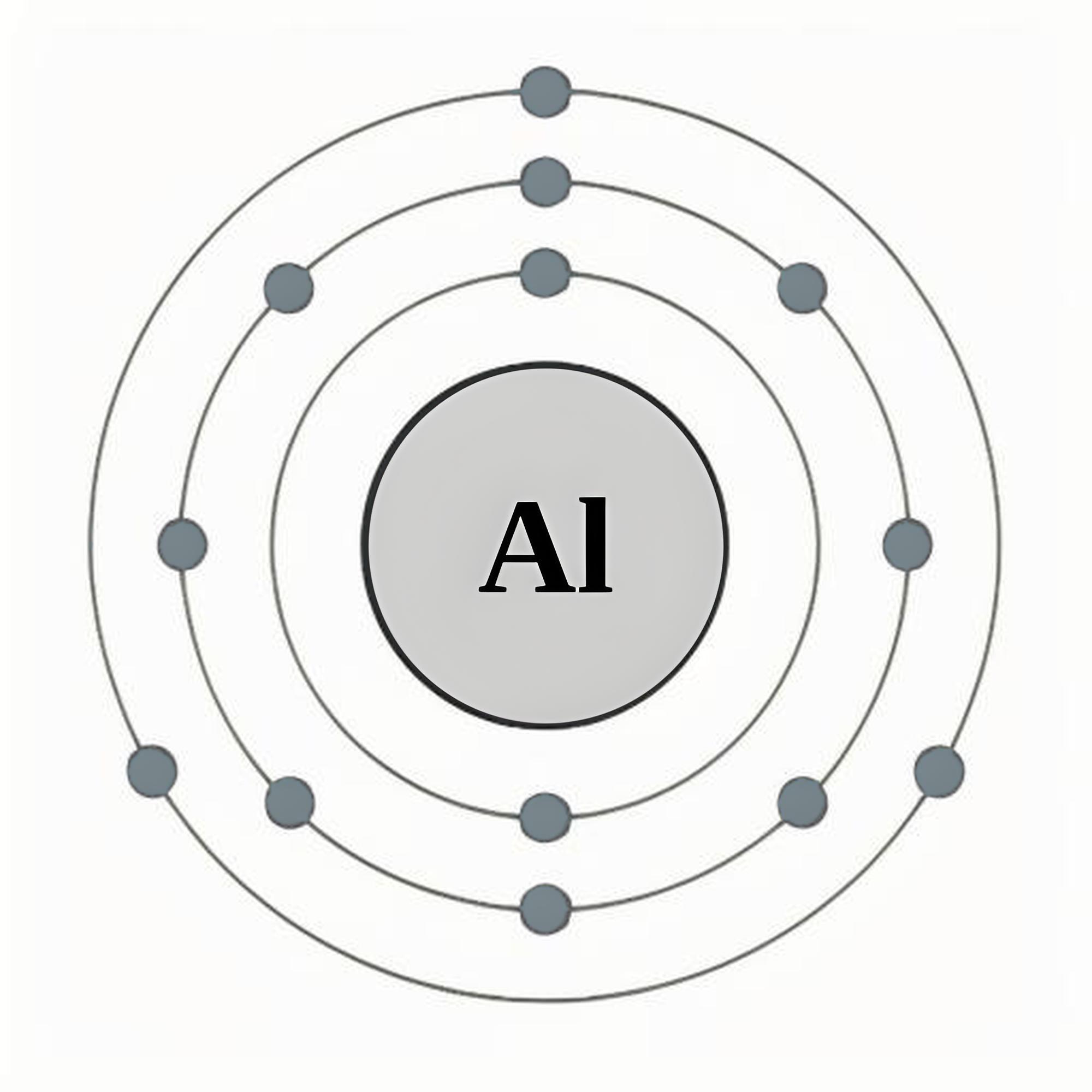

Aluminum

Physical Properties:

Conductivity: Aluminum is a good conductor of electricity, with conductivity second only to silver, copper, and gold.

Melting Point: Aluminum has a relatively low melting point (660°C), making it suitable for low-temperature processes.

Ductility: Aluminum has excellent ductility and malleability, making it easy to process into various shapes.

Chemical Properties:

Oxidation: Aluminum readily forms a dense layer of aluminum oxide (Al₂O₃) on its surface, which has good insulating properties and corrosion resistance.

Reactivity: Aluminum can be highly reactive under certain conditions, such as high temperatures or strong acidic environments.

Applications:

Interconnect Material: In semiconductor devices, aluminum is commonly used to create metal interconnects, connecting different components and layers.

Packaging Material: Aluminum and its alloys are often used for packaging semiconductor devices, providing mechanical protection and heat dissipation.

Reflective Material: Aluminum has excellent reflective properties and is commonly used to make optical reflectors and optoelectronic devices.

Main Differences

Material Type:

Silicon: Semiconductor material, primarily used for manufacturing the core components of electronic devices.

Aluminum: Conductive material, primarily used for interconnects and packaging.

Physical and Chemical Properties:

Silicon: Possesses good semiconductor characteristics and readily forms an insulating layer of silicon dioxide on its surface.

Aluminum: Has excellent conductivity and ductility, and readily forms an insulating layer of aluminum oxide on its surface.

Application Areas:

Silicon: Widely used in integrated circuits, solar cells, and sensors.

Aluminum: Primarily used for metal interconnects, packaging materials, and reflective materials.

Conclusion

Silicon and aluminum play different roles in semiconductor technology. Silicon, as a semiconductor material, is the core material for manufacturing electronic devices, while aluminum, as a conductive material, is mainly used for interconnects and packaging. Their respective physical and chemical properties determine their advantages and suitability in different applications.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.